-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Study on the microstructure, properties and application of Nb521 niobium-tungsten alloy

Release time:

2025-01-13

0 Introduction

The Nb521 niobium-tungsten alloy (Nb-5W-2Mo-1Zr) developed in my country is similar to the 5BMV alloy of the former Soviet Union. The 5BMV alloy was used in the manufacture of the thrust chamber of a two-element liquid rocket engine in the former Soviet Union. Under the protection of the high-temperature anti-oxidation coating of molybdenum silicide, the working temperature of the thrust chamber can reach about 1550℃, which greatly reduces the propellant flow used to cool the combustion chamber, which is beneficial to improve the performance of the engine.

With the need for model development, the use of Nb521 niobium-tungsten alloy in my country's aerospace field has become more extensive. It is not only used in two-element liquid rocket engines, but also in some high-temperature components of other high-speed aircraft. This paper studies the room temperature, high temperature properties and microstructure changes of the alloy, and uses the spinning method to trial-produce the nozzle extension section for the engine, and studies the high temperature properties and room temperature formability of the material.

1 Experiment

1. 1 Materials

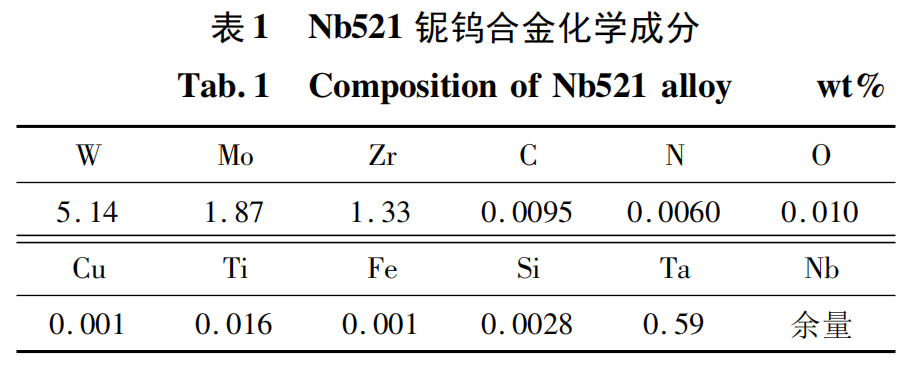

Nb521 niobium tungsten alloy plates and bars are in a recrystallized state, and the composition is shown in Table 1.

1. 2 Experimental methods and analysis

The recrystallized Nb521 niobium tungsten alloy plates and bars are processed into room temperature and high temperature tensile specimens, and tensile tests are carried out on room temperature and high temperature tensile testing machines respectively to determine the room temperature mechanical properties of Nb521 niobium tungsten alloy. The carbide strengthening phase in Nb521 niobium tungsten alloy is calibrated by X-ray diffraction. Nb521 niobium tungsten alloy is processed into small test bars (Ф3 mm ×100mm), and then a high temperature anti-oxidation coating is infiltrated on the surface of the small test bars. The test bars are heated by electricity and kept for a long time at 1450, 1500, 1550, 1600, 1700 and 1800℃, respectively. The changes of the strengthening phase during high temperature and long time holding are observed and analyzed by scanning electron microscopy, and the precipitated strengthening phase is calibrated by transmission electron microscopy. After the anti-oxidation coating was prepared on the surface of the high-temperature tensile specimen, its high-temperature tensile properties were measured.

2 Results and analysis

2. 1 Room temperature mechanical properties and structure

2. 1. 1 Room temperature mechanical properties

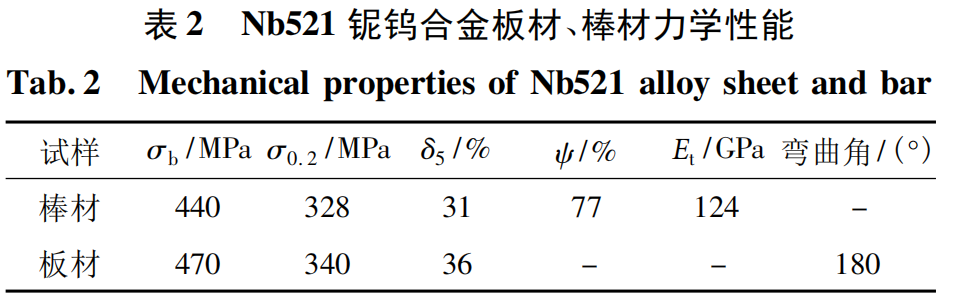

Table 2 shows the room temperature mechanical properties of Nb521 niobium tungsten alloy plates and bars. It can be seen from Table 2 that the material has good plasticity at room temperature and is suitable for forming parts through plastic processing methods such as spinning.

2. 1. 2 Room temperature structure

Figure 1 shows the room temperature structure of recrystallized Nb521 niobium tungsten alloy plates and bars. It can be seen that it is an equiaxed recrystallized structure. Figure 2 is a scanning electron microscope morphology of carbides in the finished plate. It can be seen that fine carbides are dispersed in the grains, and larger lamellar carbides are distributed at the grain boundaries. These carbides play a role in pinning grain boundaries and dislocations during high-temperature deformation and improving the high-temperature strength of the plate.

Nb521 niobium tungsten alloy contains various types of carbides such as MC, M2C and M3C2. Fine and stable carbides, nitrides and oxide dispersions are the most effective high temperature strengthening method for niobium alloys [1]. The carbide strengthening phases in niobium tungsten alloys are dispersed (Nb, Zr) C and Nb2C [2]. The carbides in the plate were calibrated by X-ray diffraction, and the calibration result was ZrC. ZrC is a dispersed stable phase, which mainly plays a role in dispersion strengthening for niobium tungsten alloys.

2.2 High temperature performance and structure

2.2.1 High temperature mechanical properties

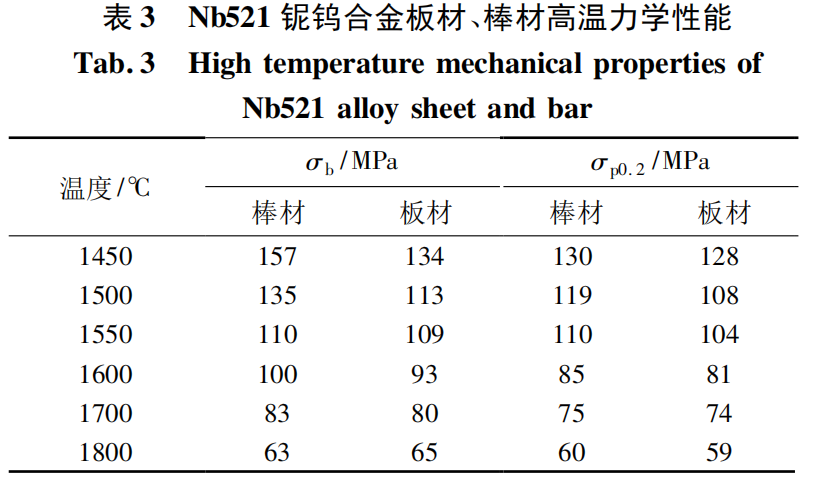

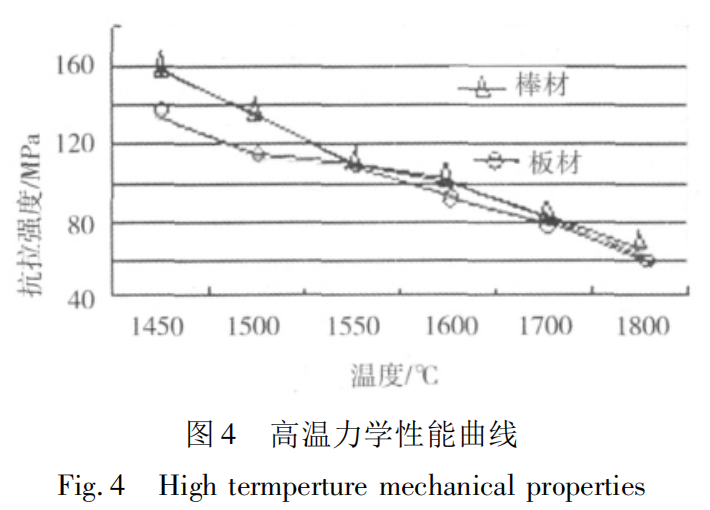

Table 3 shows the high temperature mechanical properties of Nb521 niobium tungsten alloy plates and bars. The engine thrust chamber requires that the tensile strength of the material at 1600℃ is generally not less than 60 MPa. It can be seen from Table 3 that the new material has good high temperature performance and fully meets the use requirements of the engine thrust chamber.

2. 2.2 High temperature structure

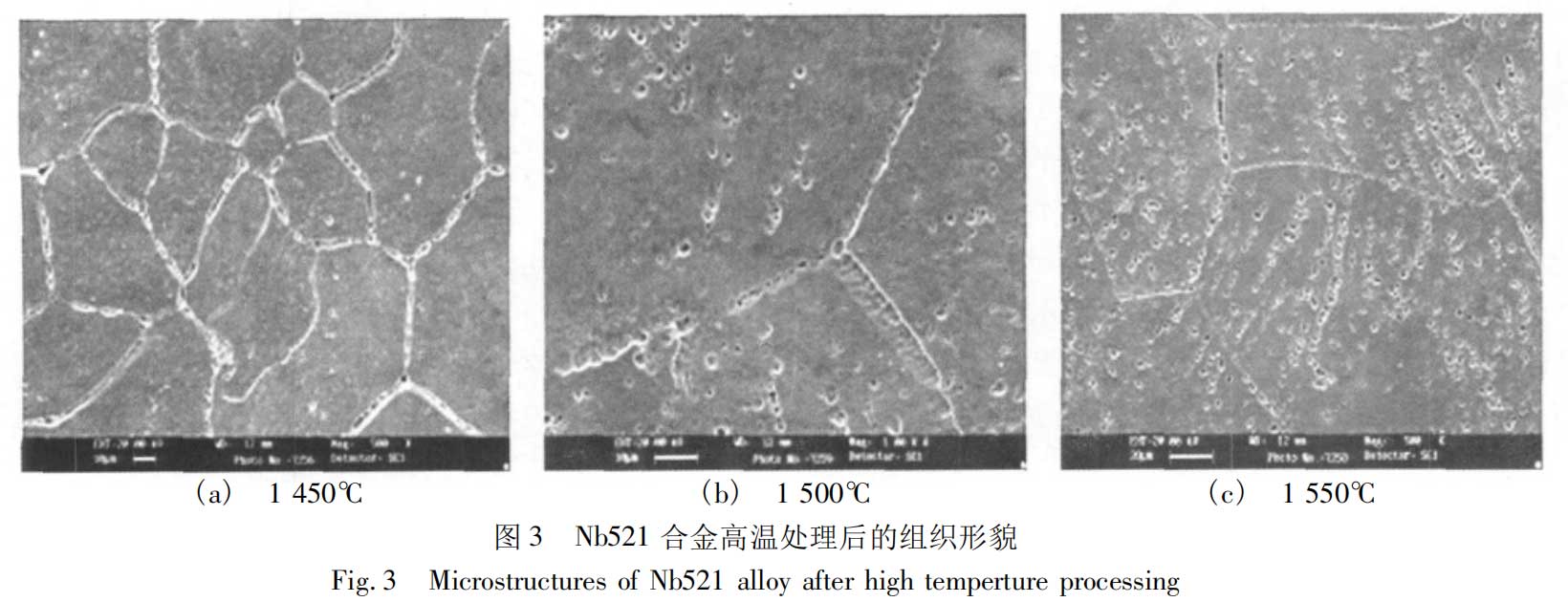

Figure 3 is a scanning photo of niobium tungsten alloy after being kept at 1450, 1500 and 1550℃ for 8 hours respectively.

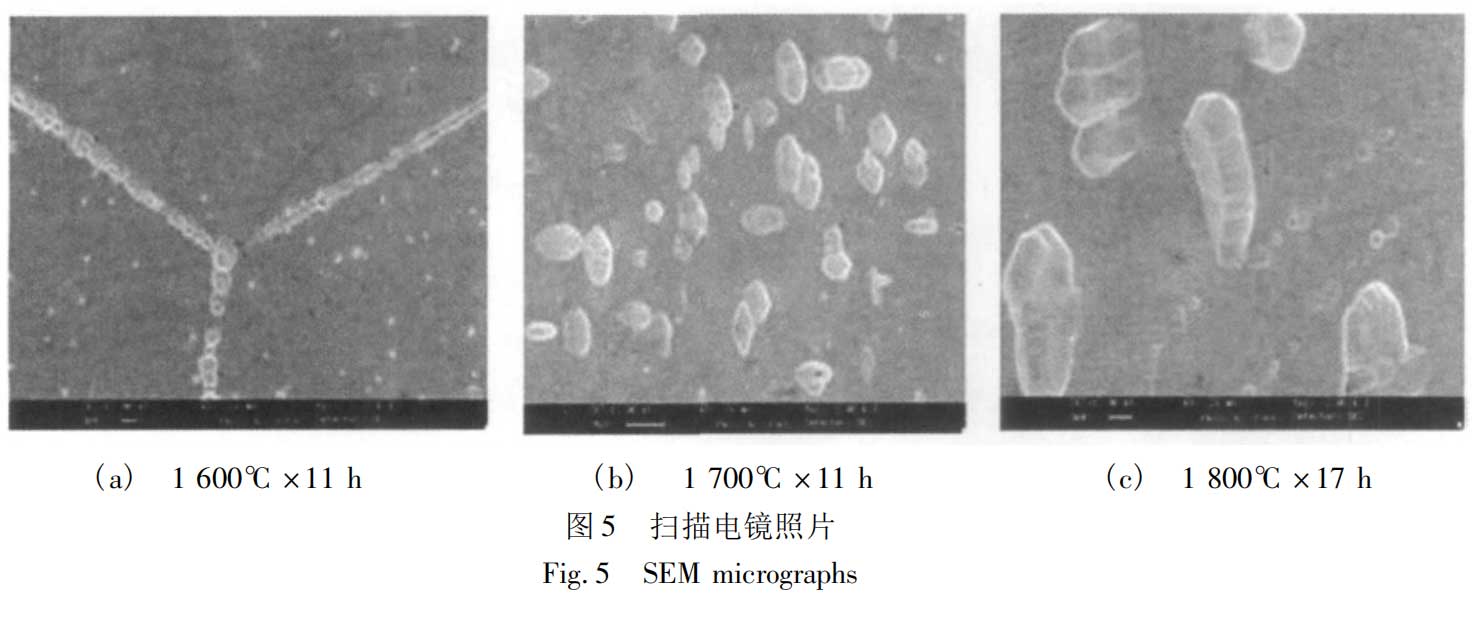

As shown in Figure 3, with the increase of heating temperature, the strengthening phase begins to precipitate and aggregate and grow. Carbide, as the high temperature strengthening phase of niobium tungsten alloy, can only play a good high temperature strengthening role when it is dispersed. Its aggregation and growth will inevitably lead to a decrease in the high temperature strength of niobium tungsten alloy. The high temperature mechanical property curve in Figure 4 also illustrates the relationship between strength decrease and temperature. Figure 5 is a scanning electron microscope photo of niobium tungsten alloy after being kept at 1600, 1700℃ for 11 hours and 1800℃ for 17 hours. It can be seen that when niobium tungsten alloy is heated at 1600℃ for a long time, the precipitated carbide phase morphology becomes almost spherical and distributed along the grain boundary.

When the holding time is the same, as the temperature increases, carbides precipitate and grow on the subgrain boundaries and matrix, and the shape of the carbides is no longer spherical, but has a certain crystallographic orientation.

3 Application of Nb521 niobium tungsten alloy in liquid rocket engines

3.1 Spinning of nozzle extension section for engine body

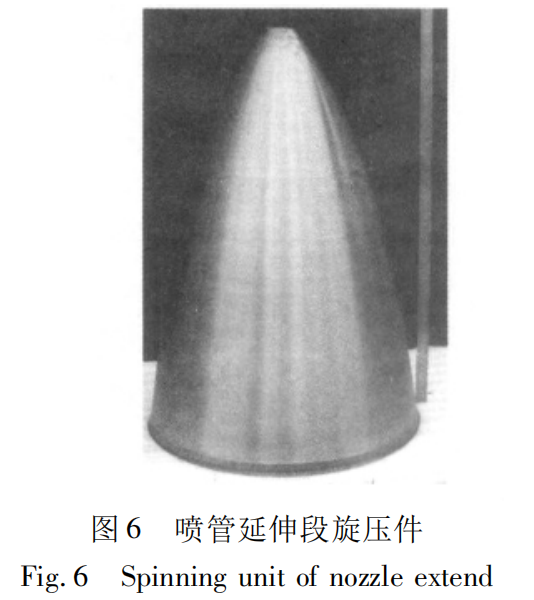

The workpiece shown in Figure 6 is a nozzle extension section formed by spinning of niobium tungsten alloy sheet. The workpiece is 950 mm high, the nozzle diameter is Ф650 mm, the minimum end diameter is Ф60 mm, and the wall thickness is uniformly transitioned from 1.5 mm to 0.55 mm at the nozzle.

Through the spinning test, the newly developed niobium tungsten alloy has good room temperature forming performance, and the limit thinning rate of the material should be around 70%.

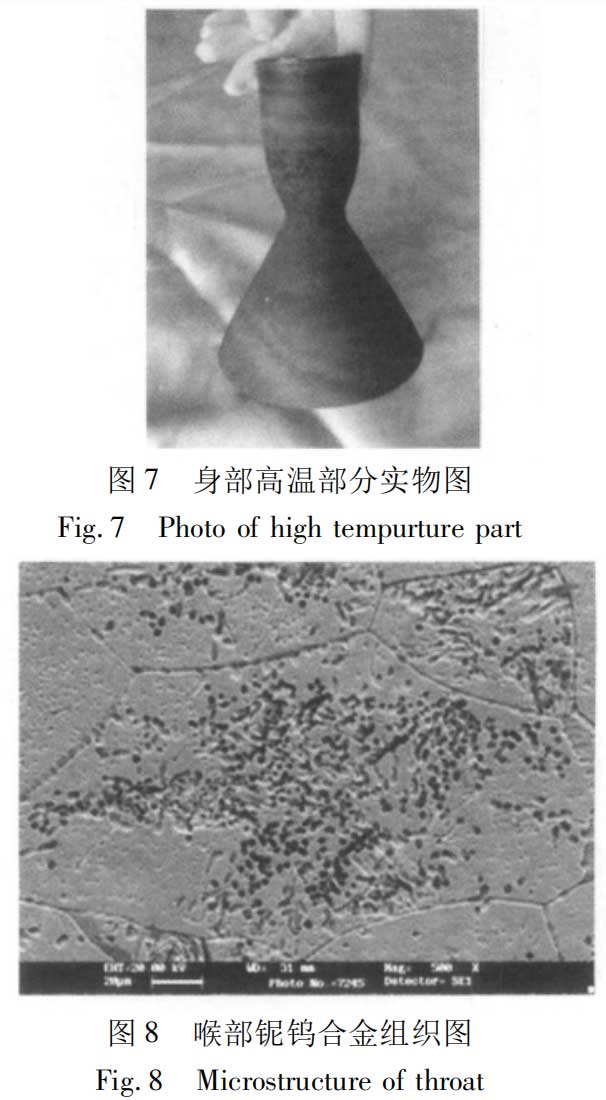

3. 2 Nb521 niobium tungsten alloy body

The engine body made of Nb521 niobium tungsten alloy was subjected to several hours of hot test after being sprayed with high-temperature anti-oxidation coating on the surface. Figure 7 shows the appearance of the high-temperature part of the body during the hot test, where the highest temperature is at the throat (the smallest diameter). Figure 8 shows the structure of Nb521 niobium tungsten alloy corresponding to the throat. The structure of the niobium tungsten alloy in Figure 8 is closest to the alloy microstructure in Figure 3 (c). Therefore, it can be judged that the temperature of the high-temperature part of the engine thrust chamber body should be around 1550℃ when working. It can be seen that the newly developed niobium tungsten alloy has excellent high-temperature performance and can fully meet the requirements of the engine body for high-temperature performance of materials.

4 Conclusion

(1) Nb521 niobium tungsten alloy contains a variety of carbide strengthening phases. The aggregation and growth of strengthening phases will reduce the high-temperature strength of the material.

(2) Nb521 niobium tungsten alloy has excellent room temperature plastic deformation ability and can form more complex workpieces at room temperature.

(3) Nb521 niobium tungsten alloy has good high temperature mechanical properties and can meet the use requirements of engines at 1550℃.

Paper citation information

Aerospace Materials and Technology http://www.yhclgy.com 2012 Issue 1 Study on the microstructure, properties and application of Nb521 niobium tungsten alloy

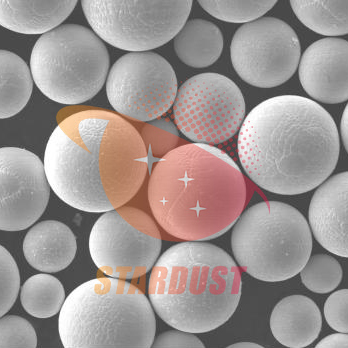

Spherical Nb521 alloy powder produced by Stardust Technology

1-RF plasma spheroidization process

2-High sphericity, high purity and low oxygen, uniform particle size distribution

3-Better fluidity, uniform powder spreading and higher printing accuracy

4-Widely used in engine components, thermal protection materials and thermal shielding materials in the aerospace field

http://en.stardusttech.cn/products_det/109.html

For more details, please contact Vicky Zhang +86-13318326185

News

-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Stardust Technology (Guangdong) Co., Ltd.

101, Building 1, Liandong Youzhi Zone, Senshuji Road, Nansha Community, Danzao Town, Nanhai District, Foshan City,Guangdong Pro.,China

QR code