Microstructure and Mechanical Properties of Refractory High-Entropy Alloy Ti30V30Cr5Zr5Ta15W15 Prepared from Low-Purity Raw Materials

Release time:

2025-09-23

In recent years, refractory high-entropy alloys have garnered significant attention due to their outstanding properties, including exceptional high-temperature strength [1-3], excellent radiation resistance [4-5], and superior corrosion resistance [6-7]. It is well-known that the purity of raw materials significantly impacts the stability of metallic material properties, primarily due to the influence of impurity elements on microstructure and mechanical behavior. Taking nickel-based superalloys [8] and titanium alloys [9], the presence of elements such as B, C, O, P, and S can enhance alloy strength by promoting dislocation motion. However, these elements also induce embrittlement at grain boundaries, reducing the alloy's ductility. Therefore, strict control of these element contents is essential in actual production and processing to mitigate their impact on performance stability [10]. The strengthening effect of nonmetallic interstitial atoms on alloy properties has also been reported in refractory high-entropy alloys [11-14]. For instance, N doping elevated the room-temperature yield strength of HfNbTaTiV alloys from 1036 MPa to 2716 MPa, with the (HfNbTaTiV)90N10 alloy maintaining a yield strength of 279 MPa at 1400°C [13]. Minimal Si addition reduces the density of NbTaMoW alloys while simultaneously enhancing their strength and ductility [14]. Current research on refractory high-entropy alloys predominantly focuses on high-purity raw materials, yet impurity elements within low-purity feedstocks significantly influence the mechanical properties of the resulting alloys. Reports indicate that the same refractory high-entropy alloy prepared via vacuum arc melting exhibits distinct performance variations due to raw material purity differences. For instance, TiZrHfNb alloy produced from higher-purity raw materials (>99.9 mass%) demonstrated a yield strength of 750 MPa [15], whereas TiZrHfNb alloy produced from relatively lower-purity raw materials (>99.8 mass%) exhibited a yield strength of 879 MPa[16]. TiZrHfNb alloys prepared from high-purity raw materials (>99.9 mass%) from different batches may also exhibit significant performance variations[17]. These results indicate that subtle purity differences in raw materials can affect the performance stability of refractory high-entropy alloys, while using lower-purity raw materials can sometimes even enhance the alloy's mechanical properties. Furthermore, employing low-purity raw materials substantially reduces the material cost of refractory high-entropy alloys. Therefore, investigating the impact of low-purity raw materials on the performance stability of prepared refractory high-entropy alloys is crucial for developing low-cost, high-performance alloys and expanding their industrial application prospects.

Previous work has employed high-purity raw materials to prepare Ti30V30Cr5Zr5Ta30-xWx (x = 5, 10, 15, and 20) refractory high-entropy alloys using high-purity raw materials. Detailed investigations of their microstructure and mechanical properties revealed simple phase compositions, excellent phase stability, and superior mechanical properties [18]. Based on this, this study selects the Ti30V30Cr5Zr5Ta15W15 alloy—the optimal alloy in this system in terms of comprehensive properties—as the research subject. It investigates the effects of low-purity raw materials on the microstructure and mechanical properties of this alloy. By doping C and N elements into the alloy, the study further explores the mechanisms by which impurity elements in low-purity raw materials influence its microstructure and properties.

1 Experimental Materials and Methods

Vacuum arc melting was employed to prepare the refractory high-entropy alloy Ti₃₀V₃₀Cr₅Zr₅Ta₁₅W₁₅, wherein the purity of high-purity metal raw materials was no less than 99.9 mass%. For low-purity metal raw materials, Ti, V, Cr, and Zr were 99.6, 99.7, 99.2, and 97.6 mass%, respectively. Non-metallic elements C and N were added in the form of WC and TiN powders. For simplified distinction, alloys prepared from high-purity and low-purity raw materials are denoted as Ta15W15 and LP-Ta15W15, respectively, while C- and N-doped alloys are labeled as Ta15W15C0.5 and Ta15W15N0.5. Cost analysis of the two purity grades revealed that the raw material cost for LP-Ta15W15 alloy decreased by nearly 70% compared to high-purity raw materials. Phase composition was determined using a D/MAX2500VL/PC rotating target X-ray diffractometer (XRD) with a scanning range of 10° to 110°. A SU8020 scanning electron microscope (SEM) was employed to observe the microstructure and fracture morphology of the alloy. The integrated energy dispersive spectrometer (EDS) characterized the elemental content and distribution within the alloy. A universal testing machine (MTS, NSS C51.105 GL) measured the mechanical properties of the alloy at room temperature and elevated temperatures, with an electronic extensometer configured for room-temperature compression testing. High-temperature compression tests were conducted under an argon protective atmosphere with a heating rate of 15 °C/min and a holding time of 10 min. Test specimens measured 3 mm × 3 mm × 6 mm, and the compression strain rate was 1 × 10⁻³ s⁻¹. Alloy hardness values were measured using a Vickers hardness tester (HV-1000SA) with an applied load of 1000 g and a dwell time of 10 s. To minimize experimental error, mechanical property tests were repeated three times for each alloy, and hardness measurements were performed ten times, with data analyzed using the average values.

2 Experimental Results and Discussion

2.1 Phase Composition

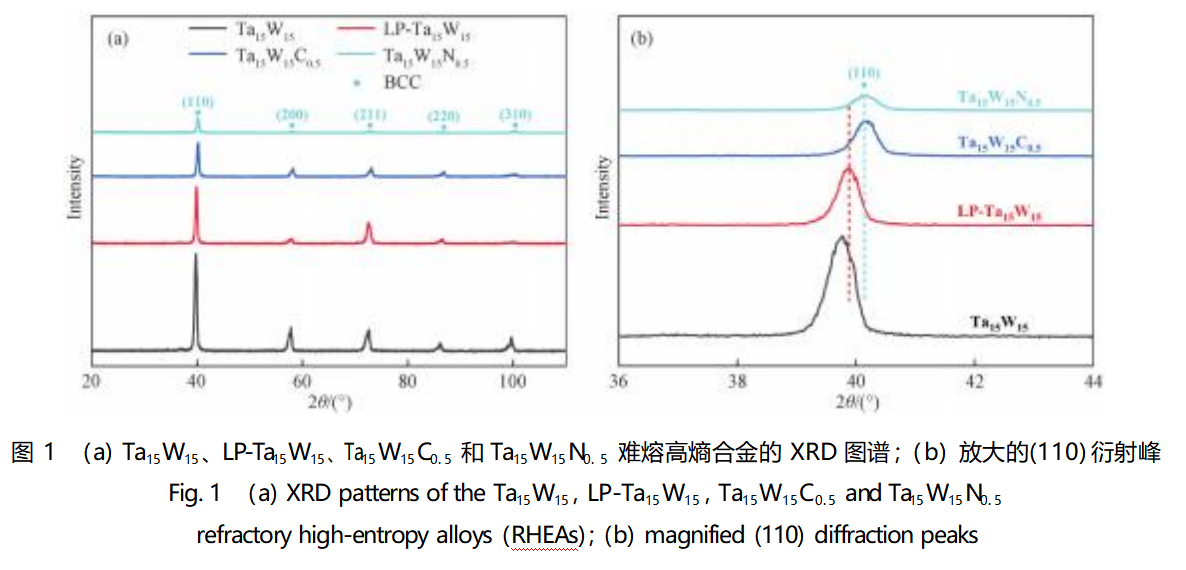

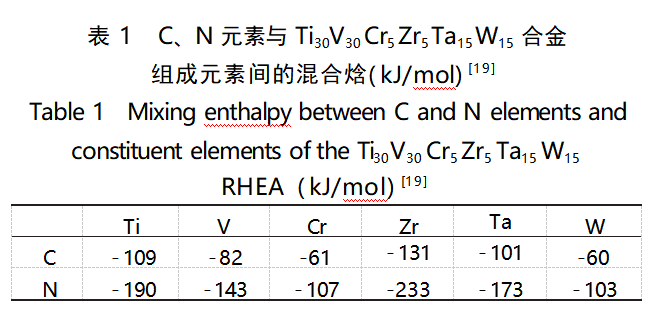

The XRD patterns of the refractory high-entropy alloys Ta15W15 and LP-Ta15W15 are shown in Figure 1. As seen in Figure 1(a), the phase composition of the LP-Ta15W15 alloy is consistent with that of the Ta15W15 alloy, exhibiting a single BCC phase with no other phase precipitates observed. Figure 1(b) presents an enlarged view of the (110) diffraction peak from Figure 1(a). It reveals that the (110) diffraction peak of the LP-Ta15W15 alloy shifts toward higher diffraction angles, indicating a reduction in the lattice constant of its BCC phase. This may be related to the mixing enthalpy between impurity elements in low-purity raw materials and the main alloy elements. Further characterization of the phase composition of Ta15W15C0.5 and Ta15W15N0.5 revealed the same phenomenon as in the LP-Ta15W15 alloy. Compared to LP-Ta15W15, the (110) diffraction peaks of Ta15W15C0.5 and Ta15W15N0.5 shifted more significantly to the right, confirming the influence of impurity elements on the alloy lattice constant. As shown in Table 1, the mixing enthalpies between C, N, and the alloy's constituent elements are all small negative values [19], indicating strong bonding between the main alloying elements and C/N. This promotes carbide and nitride formation, thereby reducing the alloy's lattice constant[20].

2.2 Microstructure

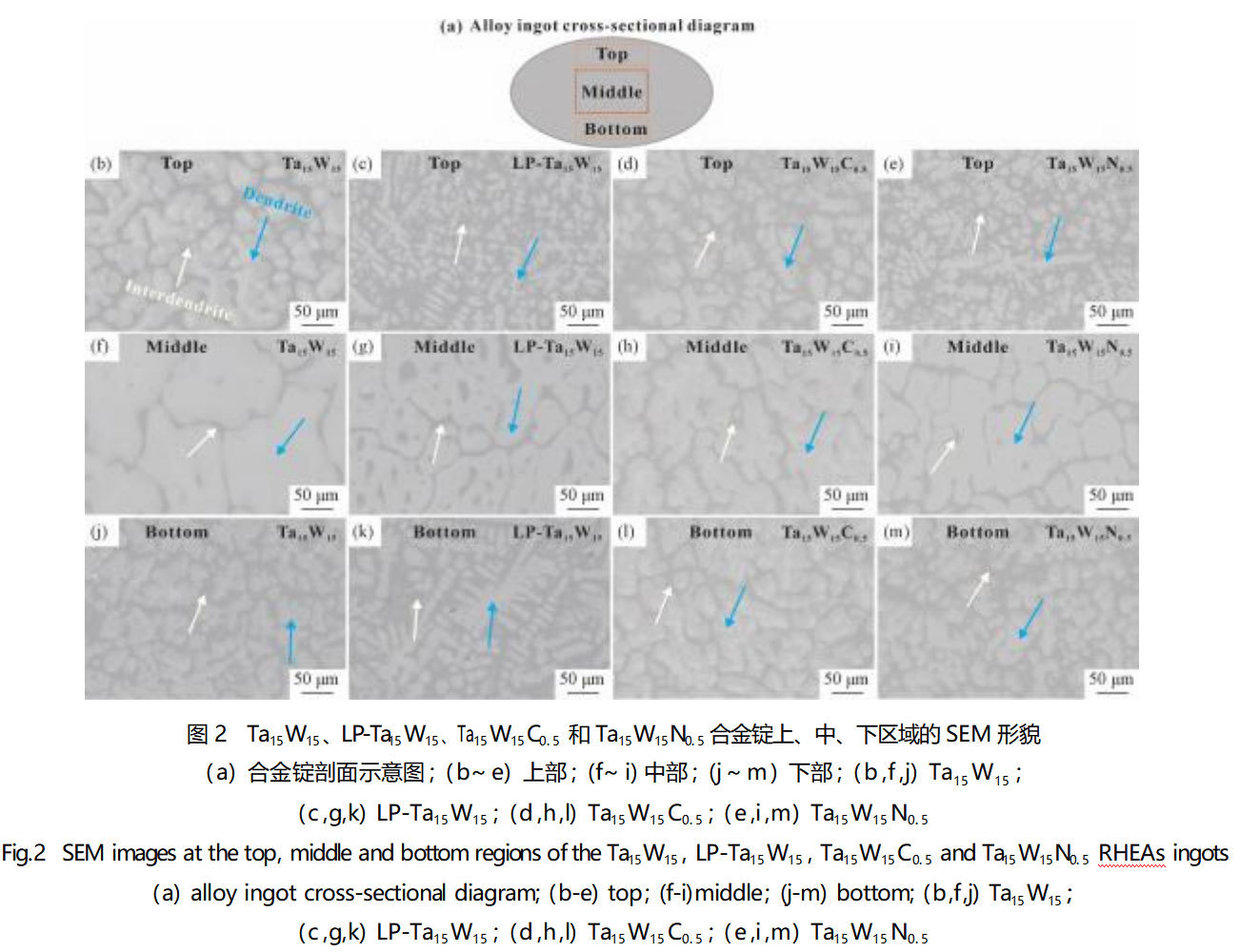

Studies have found that refractory high-entropy alloys prepared by vacuum arc melting typically exhibit certain microstructural variations across different regions due to differences in cooling rates [21-22]. In this study, to comprehensively evaluate the influence of low-purity raw materials on the microstructure of refractory high-entropy alloys, three distinct regions—upper, middle, and lower—of the alloy ingot were analyzed (Figure 2a). The microstructures of Ta15W15 and LP-Ta15W15 refractory high-entropy alloys in the upper, middle, and lower regions are shown in Figure 2. Compared to the Ta15W15 alloy, the LP-Ta15W15 alloy exhibits significant dendrite refinement in all three regions. This refinement is likely attributed to impurity elements in the low-purity raw materials acting as heterogeneous nucleation sites [23]. Dendritic refinement was also observed in the microstructures of Ta15W15 C0.5 and Ta15W15 N0.5 alloys across different regions (Figure 2), further confirming the possibility of impurity elements acting as heterogeneous nucleation sites to refine the alloy microstructure [24]. However, the microstructures of the LP-Ta15W15 alloy in the middle and lower layers exhibit distinct differences compared to those of the Ta15W15C0.5 and Ta15W15N0.5 alloys. Specifically, the intermediate layer of LP-Ta15W15 exhibits distinct inter-dendritic regions within its dendrites, while its lower layer microstructure closely resembles dendritic structures. In contrast, the inter-dendritic regions in the intermediate layer of Ta15W15 C0.5 and Ta15W15 N0.5 are less pronounced, and their lower layers display microstructures more akin to equiaxed grains. This may be attributed to the presence of other impurity elements in the low-purity raw materials of the LP-Ta15W15 alloy. These elements distributed within the dendrites during solidification disrupted the continuity of the matrix.

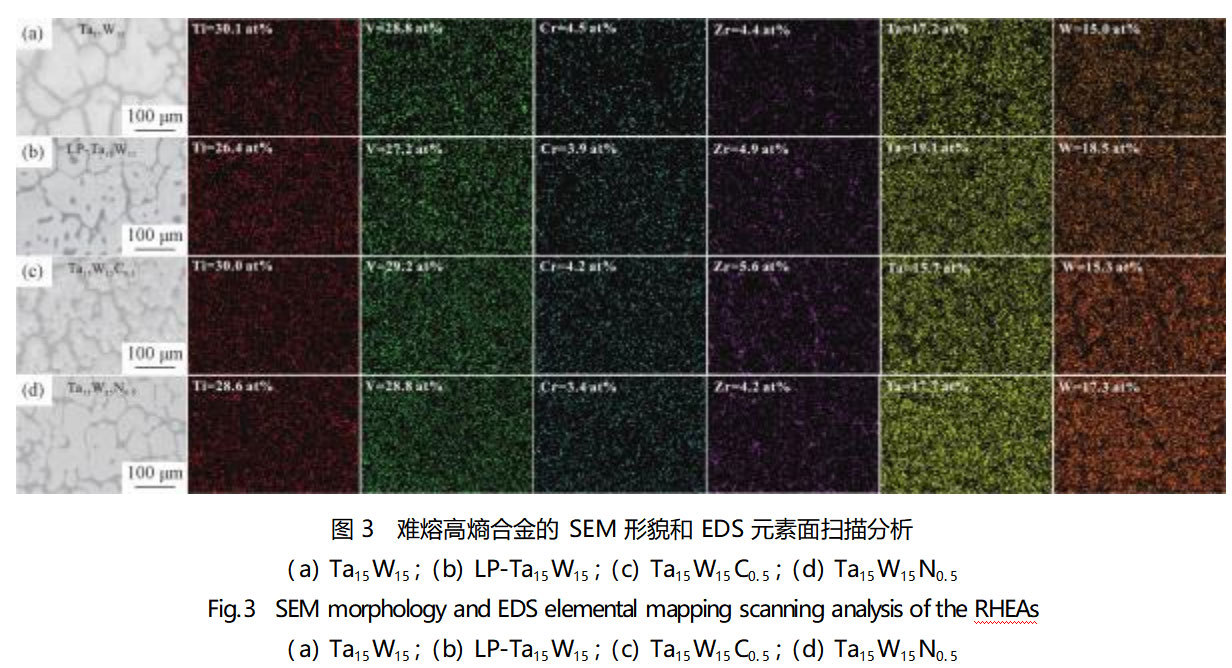

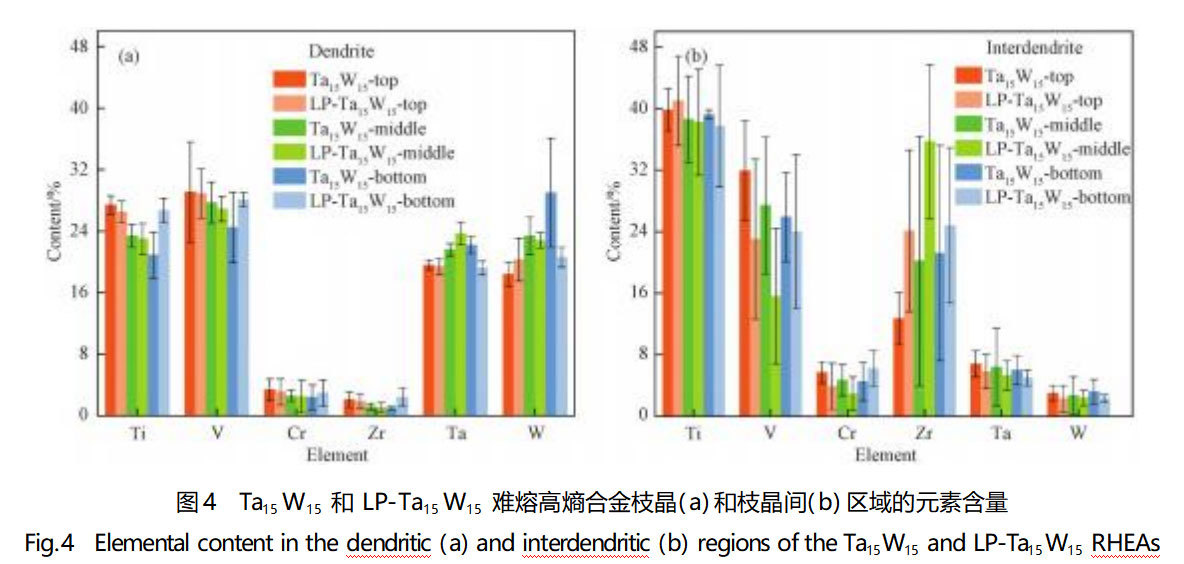

EDS scanning results for the intergranular regions of Ta15W15 and LP-Ta15W15 alloys are shown in Figure 3(a–b). Due to the low concentration of impurity elements in the low-purity raw materials, the testing precision of EDS makes it difficult to accurately measure their content; therefore, only the analysis results for the alloy's constituent elements are presented here. The study revealed that both Ta15W15 and LP-Ta15W15 alloys exhibit segregation phenomena, and the enrichment of elements within and between dendrites is consistent with previously reported results [18]. Specifically, Ti, Cr, and Zr elements predominantly enriched in the inter-dendritic regions, while Ta and W elements enriched within dendrites. V element distribution remained relatively uniform. Measured values for each alloy element generally aligned with their theoretical design values. Given the low C and N doping levels, EDS results for Ta15W15C0.5 and Ta15W15N0.5 alloys also align with the aforementioned findings (Fig. 3c–3d). To further analyze the impact of low-purity raw materials on alloy element enrichment, EDS point analysis was conducted on dendrites and inter-dendritic regions in the upper, middle, and lower zones of Ta15W15 and LP-Ta15W15 alloys. Results are shown in Figure 4. It can be observed that the content of each constituent element in the dendrites and inter-dendritic regions of the Ta15W15 and LP-Ta15W15 alloys does not show significant differences across these zones. Overall, Ti, Cr, and Zr exhibit higher concentrations in the inter-dendritic regions, while Ta and W are more abundant in the dendritic regions. Although the content error of V in the inter-dendritic regions was higher than that in the dendritic regions, it still exhibited a relatively uniform distribution, consistent with the results shown in Figure 3. These results indicate that impurity elements in low-purity raw materials have a limited influence on the element distribution in the prepared alloy, and the element segregation observed in the alloy is primarily related to the melting points and mixing enthalpies of the elements [25].

2.3 Mechanical Properties

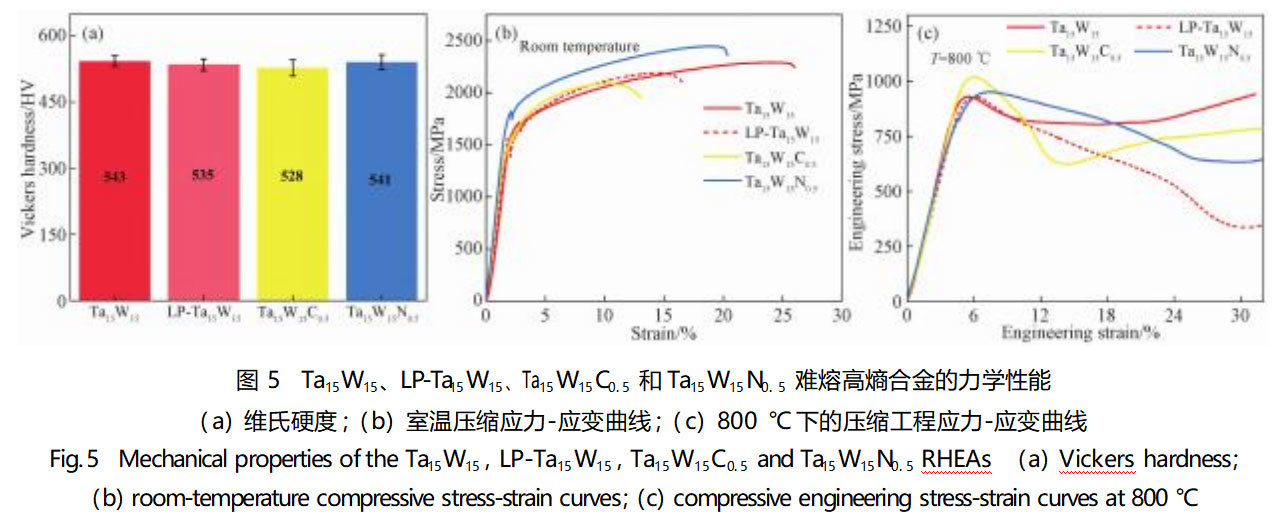

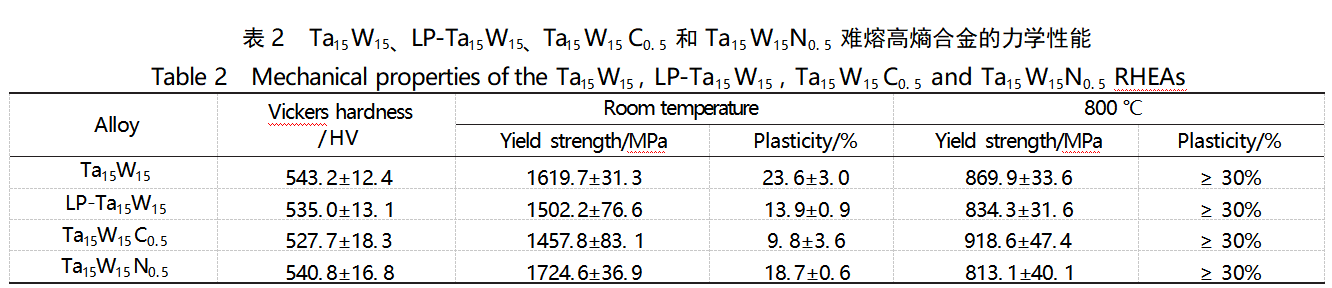

Considering microstructural variations in the alloy due to differing cooling rates, mechanical property test specimens were all taken from the central portion of the alloy. Figure 5 shows the Vickers hardness and room-temperature and high-temperature compressive mechanical properties of the Ta15W15 and LP-Ta15W15 alloys, with specific data presented in Table 2. Figure 5(a) reveals that the hardness values of LP-Ta15W15 and Ta15W15 alloys are essentially comparable within experimental error limits. The carbon-doped alloy exhibits only a slight decrease in hardness, while the nitrogen-doped alloy shows no significant change. This result indicates that impurity elements in low-purity raw materials have a minor effect on the hardness of the Ta15W15 alloy. As shown in Figure 5(b), the room-temperature plasticity of the LP-Ta15W15 alloy decreased significantly compared to the Ta15W15 alloy, dropping from 23.6% to 13.9%. Meanwhile, the mean yield strength decreased from 1619.7 MPa to 1502.2 MPa. The differing mechanical properties of alloys prepared from low-purity raw materials may also stem from the distinct effects of various impurity elements on alloy strength and plasticity. The changes in room-temperature mechanical properties of Ta15W15C0.5 and Ta15W15N0.5 alloys further corroborate this point. As shown in Figure 5(b), C doping reduced the alloy's room-temperature strength, while N doping increased it. Compared to the Ta15W15 alloy, the Ta15W15C0.5 alloy exhibited significantly reduced plasticity, whereas the Ta15W15N0.5 alloy showed a smaller decrease in plasticity. The aggregation of nonmetallic impurity elements at grain boundaries causes grain boundary embrittlement. Additionally, the strong bonding between C and elements such as Ti and Zr enriched in dendrites impairs the cooperative deformation capability between adjacent grains during deformation, thereby reducing the alloy's plasticity [26]. In contrast, the effect of N on room-temperature plasticity differs significantly from that of C.

At 800°C, the high-temperature strength of LP-Ta15W15 alloy is slightly lower than that of Ta15W15 alloy (Figure 5c). Notably, the high-temperature strength of the Ta15W15C0.5 alloy is significantly higher than that of the Ta15W15 alloy, while the Ta15W15N0.5 alloy exhibits slightly lower high-temperature strength than the Ta15W15 alloy. This result is inconsistent with the changes in room-temperature strength. This discrepancy may stem from differing performance mechanisms of C and N elements at room and elevated temperatures [27-28]. Due to high-temperature softening, the high-temperature plasticity of all four alloys exceeded their room-temperature values (≥30%). Based on these results, low-purity raw materials have a minor impact on the high-temperature properties of refractory high-entropy alloys, and certain impurity elements may even enhance the alloys' high-temperature strength. Overall, compared to room-temperature plasticity, impurity elements exert a lesser influence on the strength values of refractory high-entropy alloys, and under certain conditions may even further enhance their strength. Given that practical engineering applications of alloy materials generally do not permit plastic deformation and are primarily constrained within their strength limits, this characteristic helps broaden the engineering application prospects of refractory high-entropy alloys prepared from low-purity raw materials.

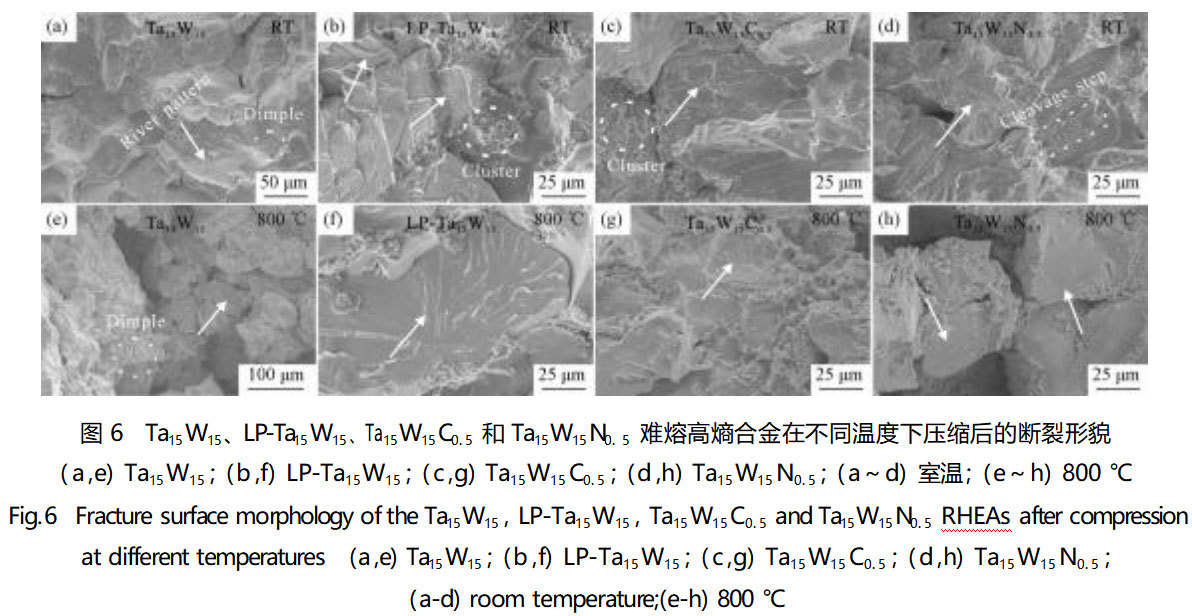

The fracture morphologies of Ta15W15 and LP-Ta15W15 alloys at room temperature and elevated temperatures are shown in Figure 6. It can be observed that the room-temperature fracture surface of the Ta15W15 alloy exhibits both ductile dimples and river-like patterns, indicating a ductile-brittle mixed fracture behavior. In contrast, the LP-Ta15W15 alloy shows a significant increase in river-like patterns on its fracture surface, corresponding to its deteriorated room-temperature plasticity. Additionally, distinct clustering features are observable on the LP-Ta15W15 fracture surface, a characteristic also present on the Ta15W15 C0.5 fracture surface (Figure 6c). These clusters induce localized stress concentrations during deformation, promoting crack initiation and significantly reducing the alloy's plasticity. In contrast, the fracture surface of the Ta15W15 N0.5 alloy exhibits dissociation steps in addition to river-like patterns (Figure 6d). This feature indicates the occurrence of localized plastic deformation, which may mitigate stress concentration to some extent. Consequently, this alloy demonstrates superior room-temperature plasticity compared to the Ta15W15 C0.5 alloy. After high-temperature compression at 800°C, the fracture morphologies of all four alloys remained consistent with their room-temperature counterparts. Their fracture mechanisms showed no significant alteration at elevated temperatures and are not elaborated upon here.

3 Conclusions

1) Compared to the Ta15W15 alloy prepared from high-purity raw materials, the LP-Ta15W15 alloy produced from low-purity raw materials exhibits refined dendrites and remains a single BCC phase. There are no significant differences in element distribution or content between the two alloys. Although the use of low-purity raw materials reduced the room-temperature plasticity of LP-Ta15W15 alloy by approximately 40%, its impact on room-temperature and high-temperature strength was relatively minor. This indicates that low-purity raw materials do not significantly affect the room-temperature and high-temperature strength of refractory high-entropy alloys, providing positive guidance for their engineering applications.

2) By doping trace amounts of C and N into the Ta15W15 alloy, it was found that the phase composition, microstructure, and room-temperature plasticity of Ta15W15C0.5 and Ta15W15N0.5 alloys corresponded to the results obtained with low-purity raw materials. However, the effects of C and N element doping on the strength of Ta15W15 alloy varied. Appropriate element doping can also help enhance its room-temperature or high-temperature strength. N doping exerted distinct effects on the strength of Ta15W15 alloy. Appropriate elemental doping further enhances its room-temperature or high-temperature strength. The C and N doping results confirm that in low-purity raw materials, impurity elements refine the dendrites and degrade the plasticity of Ta15W15 alloy, yet do not significantly alter the phase composition or element segregation behavior.

Reference: Chinese Library Classification: TG132.3 Document Type: A Article ID: 1009-6264(2025)07-0098-08

Microstructure and Mechanical Properties of Refractory High-Entropy Alloys (Ti30V30Cr5Zr5Ta15W15) Prepared from Low-Purity Raw Materials

The spherical refractory high-entropy alloy powder launched by Stardust Technology (Guangdong) Co., Ltd. is produced using radiofrequency plasma spheroidization technology. It features high purity, high sphericity, low oxygen content, and excellent flowability. This product series incorporates combinations of refractory metals such as tungsten, molybdenum, tantalum, and niobium. It is specifically designed to meet the extreme demands for high-temperature strength, creep resistance, and corrosion resistance in high-end applications including 3D printing, aerospace, and biomedical engineering. The company actively supports joint new product development with universities and research institutions and offers bulk customization services.welcome to contact our manager Cathie Zheng +86 13318326187.