Study on Spray Granulation Pre-Alloying of W-Ni-Fe Ternary Alloy Powder and Radio Frequency Plasma-Induced Densification and Spheroidization

Release time:

2025-09-18

Tungsten-nickel-iron (W-Ni-Fe) alloys, as one of the typical representatives of high-density tungsten-based alloys, are widely applied in modern scientific fields and defense and civilian industries—such as radiation shielding and guidance, industrial counterweights, nuclear energy, and energy components—due to their high density, low thermal expansion coefficient, corrosion resistance, and excellent machinability [1-5]. The production of high-density W-Ni-Fe alloy components predominantly relies on traditional powder metallurgy sintering methods. This involves mechanically premixing elemental powders, shaping them through processes like die pressing, followed by liquid-phase sintering to form green compacts, which are then machined into final parts [6]. Additive manufacturing (AM) technologies, represented by selective laser melting (SLM) and selective electron beam melting (SEBM), offer significant advantages for precision machining of complex components [7-8]. For AM, the properties of powder materials—including flowability, porosity, composition, and oxygen content—are critical to the performance of the formed components. This technology demands powders with excellent flowability and compactness. Therefore, researching the preparation processes (including composition design and densification/sphericalization methods) for dense spherical powders used in AM holds significant importance and broad application prospects for enhancing component performance.

Regarding the preparation of spherical powder materials for AM, current primary methods include atomization [9], plasma rotary electrode [10-12], and radiofrequency (RF) thermal plasma spheroidization [13-15]. Compared to other methods, RF thermal plasma offers advantages such as high temperature and purity, demonstrating significant benefits in producing high-purity spherical powders for refractory systems (tungsten, molybdenum, tantalum, and their alloys) [16-18]. Numerous researchers worldwide have employed RF thermal plasma for tungsten powder spheroidization and related process studies. For instance, Boulos et al. in Canada [19] investigated the spheroidization process of particles including tungsten powder. They found that particles around 60 μm in size exhibited low spheroidization rates, with some ultrafine particles adhering to their surfaces. Analysis suggested this was caused by high chamber pressure leading to thermal evaporation of some particles. Yu et al. [20] observed that alloying elements reduce microcracks during tungsten melting and rapid solidification. Wang et al. [21] produced spherical tungsten powder with excellent dispersion and smooth surfaces via RF thermal plasma, noting higher spheroidization rates at lower feed rates, which decreased with increased feed volume. Li et al. [22] synthesized spherical dense tungsten particles via RF thermal plasma spheroidization and further fabricated porous tungsten matrices with uniform pore distribution. Their study demonstrated that spherical dense tungsten particles facilitate obtaining porous tungsten matrices with uniform porosity. Current research predominantly focuses on RF thermal plasma spheroidization of pure tungsten powder, with limited reports on spheroidization and densification of multi-component tungsten-based alloy powders.

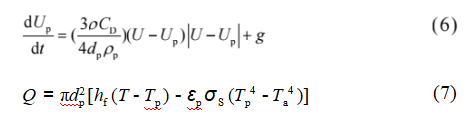

A combined approach of spray granulation and RF thermal plasma high-temperature densification/spheroidization was employed. Raw W powder, Ni powder, and Fe powder were first mixed in specific proportions and spray-granulated to produce W-Ni-Fe alloy powder with defined composition.

The results provide important references and guidance for exploring the composition design of high-density tungsten-based ternary W-Ni-Fe alloys and achieving dense spheroidization of spray-granulated alloy powders.

1 Theoretical Computational Model and Experiment

1.1 Theoretical Model for Plasma Interaction with W-Ni-Fe Ternary Alloy Powder

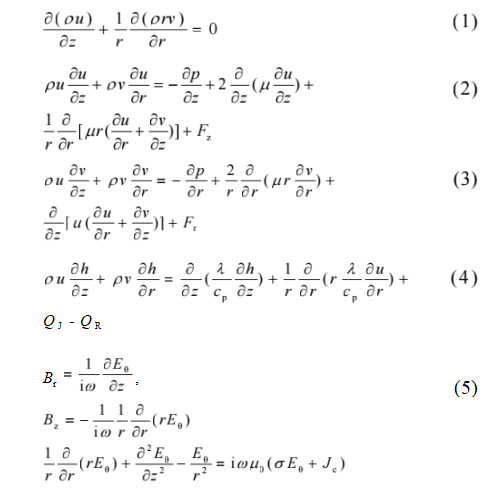

Numerical calculations were employed to investigate particle size evolution, motion trajectories, and plasma flow field distribution during plasma densification of W-Ni-Fe ternary alloy powder. To simplify the computational model, the following assumptions were made:

(1) The thermal plasma generator system is modeled as a two-dimensional axisymmetric configuration, disregarding sheath effects and cooling water influence; (2) The thermal plasma is in local thermodynamic equilibrium (i.e., the temperatures of microscopic particles within the plasma are approximately equal) and exhibits steady-state laminar flow; (3) Minor terms in the governing equations (such as pressure work, displacement current, and viscous losses) are neglected compared to the Joule heating and radiation heat terms. Consequently, the governing equations can be described as [23-24]:

In the equation, u and v represent the axial and radial velocity components, respectively; ρ, μ, λ, cp, and σ denote the plasma density, viscosity coefficient, thermal conductivity, specific heat capacity, and electrical conductivity, respectively; h and p denote enthalpy and pressure, respectively; QJ and QR denote the heat per unit volume due to Joule heating and radiation, respectively; Fz and Fr denote the axial and radial components of the Lorentz force, respectively; Jc, Eθ, Bz, and Br denote the current density, angular electric field, axial magnetic field, and radial magnetic field in the coil, respectively.

Neglecting heat transfer via particle collisions and internal thermal resistance, the particle heat transfer force model can be described as [27]:

In Equations (6) and (7): ρ and U denote plasma density and velocity, respectively; dp and Up represent particle diameter and motion velocity; ρp, CD, and g denote particle density, drag coefficient, and gravitational acceleration; hf, T, Tp, and Ta denote thermal conductivity, plasma temperature, particle temperature, and ambient temperature; σS and εp denote the Stefan-Boltzmann constant and radiation coefficient, respectively.

1.2 Pre-alloying and Plasma-Induced Spherical Compaction of W-Ni-Fe Ternary Precursor Powder

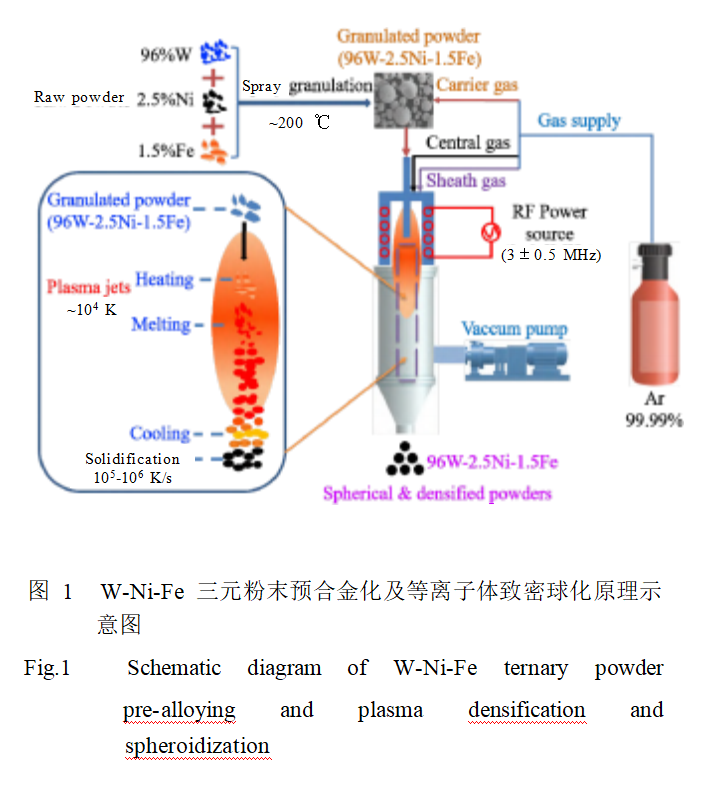

W powder, Ni powder, and Fe powder with average particle sizes in the micrometer range were mixed in a mass ratio of 96:2.5:1.5. The mixture underwent spray drying granulation at approximately 200°C to obtain high-density tungsten-based 96W-2.5Ni-1.5Fe ternary alloy powder as the precursor. The 96W-2.5Ni-1.5Fe ternary alloy powder underwent densification and spheroidization using a radiofrequency thermal plasma powder material processing system independently developed by the Southwest Institute of Physics, China National Nuclear Corporation. The system operates at a rated power of 100 kW, frequency of 3±0.5 MHz, and uses argon gas (Ar, 99.99%) as the working medium. The schematic diagram of the processing principle and experimental parameters are shown in Figure 1 and Table 1, respectively.

1.3 Performance Testing and Characterization

Magnetohydrodynamic (MHD) theory was employed to calculate and analyze the plasma flow field and particle size evolution after particle injection. The morphology, microstructure, cross-sectional features, and composition of W-Ni-Fe powder particles were characterized using powder testing methods including field emission scanning electron microscopy (SEM), metallurgical microscopy, and X-ray energy dispersive spectroscopy (EDS).

2 Results and Discussion

2.1 Analysis of W-Ni-Fe Pre-Alloyed Powder Properties

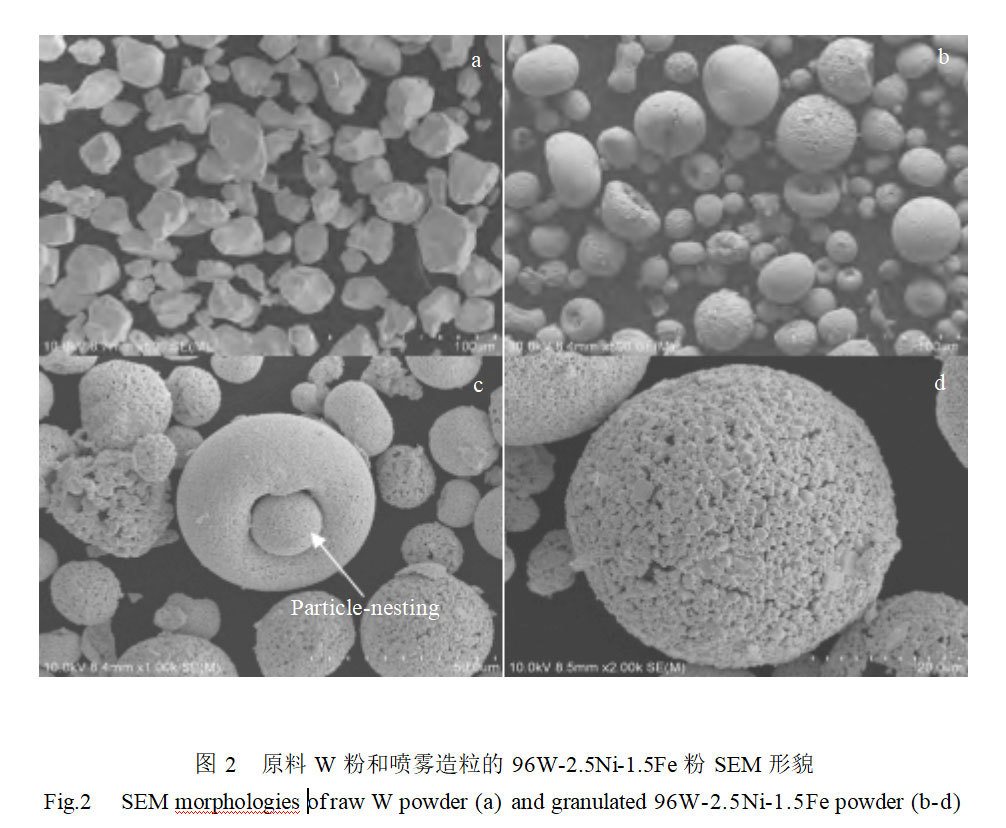

The apparent SEM morphology of the raw W powder and spray-granulated W-Ni-Fe pre-alloyed powder is shown in Figure 2. The raw powder exhibits irregular blocky shapes, while the spray-granulated 96W-2.5Ni-1.5Fe powder presents a loose microstructure with irregular spherical shapes, some being hemispherical. It features numerous voids, a rough and porous surface, and even exhibits depressions, nesting, or surface cracking in some particles (as shown in Figures 2b–2d).

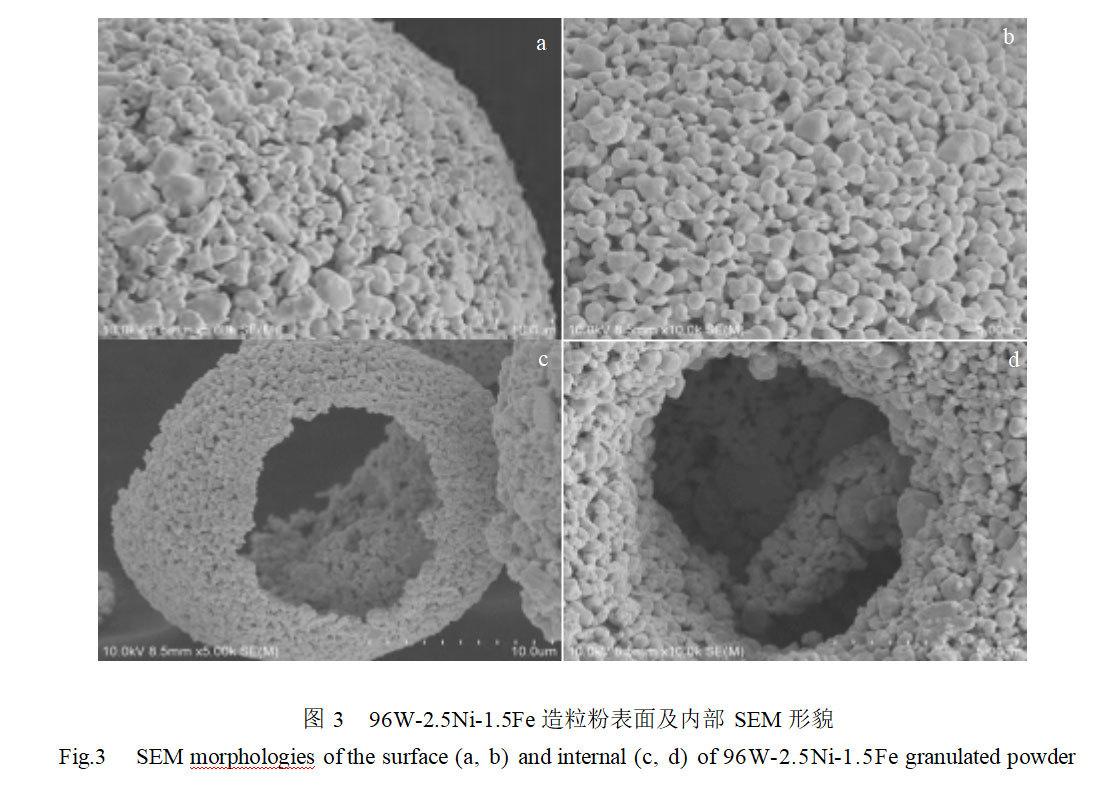

Further examination of the surface and interior of the 96W-2.5Ni-1.5Fe ternary alloy granulated powder revealed multiple particles agglomerated into single aggregates. The surface microstructure was relatively loose, exhibiting a “mesh-like” structure. Some powder particles were not fully spherical, highly prone to fragmentation, and contained numerous internal voids, as shown in Figure 3. Therefore, while spray granulation effectively controls and optimizes the elemental composition of powder materials, the resulting granulated powder typically exhibits loose porosity and brittleness prone to cracking. This poses significant disadvantages for subsequent powder processing methods like powder metallurgy or additive manufacturing, as well as for the mechanical and physical properties of the formed components. Consequently, densification and spheroidization treatment can effectively resolve these issues.

2. Theoretical Study on the RF Hot Plasma Densification Process of 2.296W-2.5Ni-1.5Fe Ternary Alloy Powder

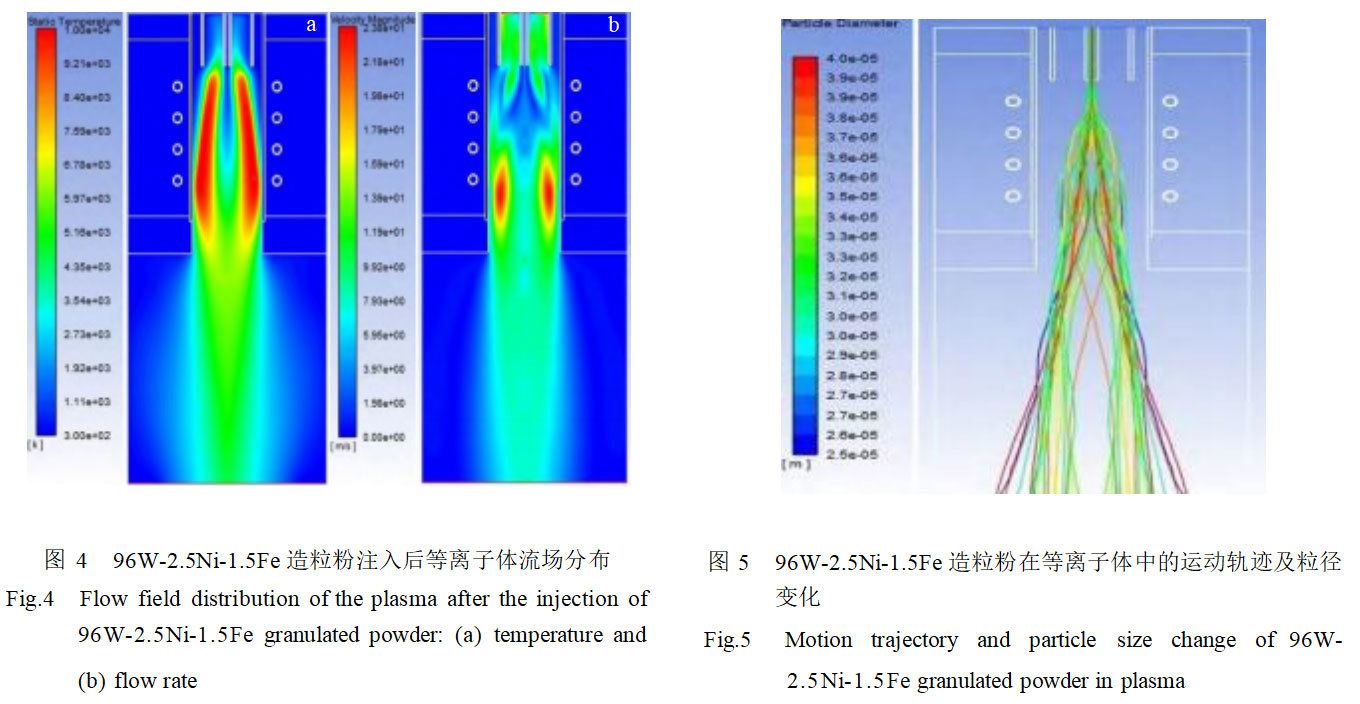

Melting granulated powder at high temperatures using radiofrequency thermal plasma followed by cooling and solidification is an effective method for densification. Among the factors influencing densification efficiency, temperature and the interaction time between particles and plasma are two critical elements. Therefore, numerical calculations were employed to investigate the flow field distribution characteristics during the densification and spheroidization process of 96W-2.5Ni-1.5Fe granulated powder injected into plasma. The results are shown in Figure 4. Figure 4a reveals that the plasma temperature distribution exhibits a lower temperature along the central axis, gradually increasing with radial distance before decreasing. The maximum temperature remains around 104 K, attributed to the skin effect of high-frequency electromagnetic induction causing higher temperatures near the coil. Additionally, the magnetic pumping effect of the RF electromagnetic field results in a plasma velocity profile characterized by lower flow speeds at the top, which prolongs the interaction time between particles and plasma. As the flow field progresses, the velocity gradually increases, reaching a maximum of approximately 23.8 m/s (as shown in Figure 4b). Thus, the flow field distribution featuring extremely high temperatures and relatively low velocities is beneficial for the densification and spheroidization of powder particles.

The kinetic behavior of particles within the plasma significantly influences heat exchange efficiency, which in turn affects densification and spheroidization outcomes. Figure 5 illustrates the motion trajectories and particle size evolution of 96W-2.5Ni-1.5Fe granulation powder within the plasma. Research indicates that particles positioned upstream in the plasma primarily concentrate in the central region, gradually dispersing toward the sides as they move downstream with the flow field. Particle size progressively decreases with increasing axial distance, theoretically confirming the densifying effect of plasma high temperatures on powders. Analysis suggests that when particles are fed axially from the center into the plasma, their motion remains relatively concentrated. while the eddy current effect generated by the high-frequency electromagnetic field draws the powder toward the sides, causing particle dispersion. Based on the distribution characteristics of the temperature field, this lateral dispersion facilitates more efficient heat exchange and melting. After heat transfer with the plasma, droplets form and then contract and solidify, reducing the particle size of the granulated powder and achieving densification.

2. Experimental Study on RF Thermal Plasma Densification of 96W-2.5Ni-1.5Fe Ternary Alloy Powder

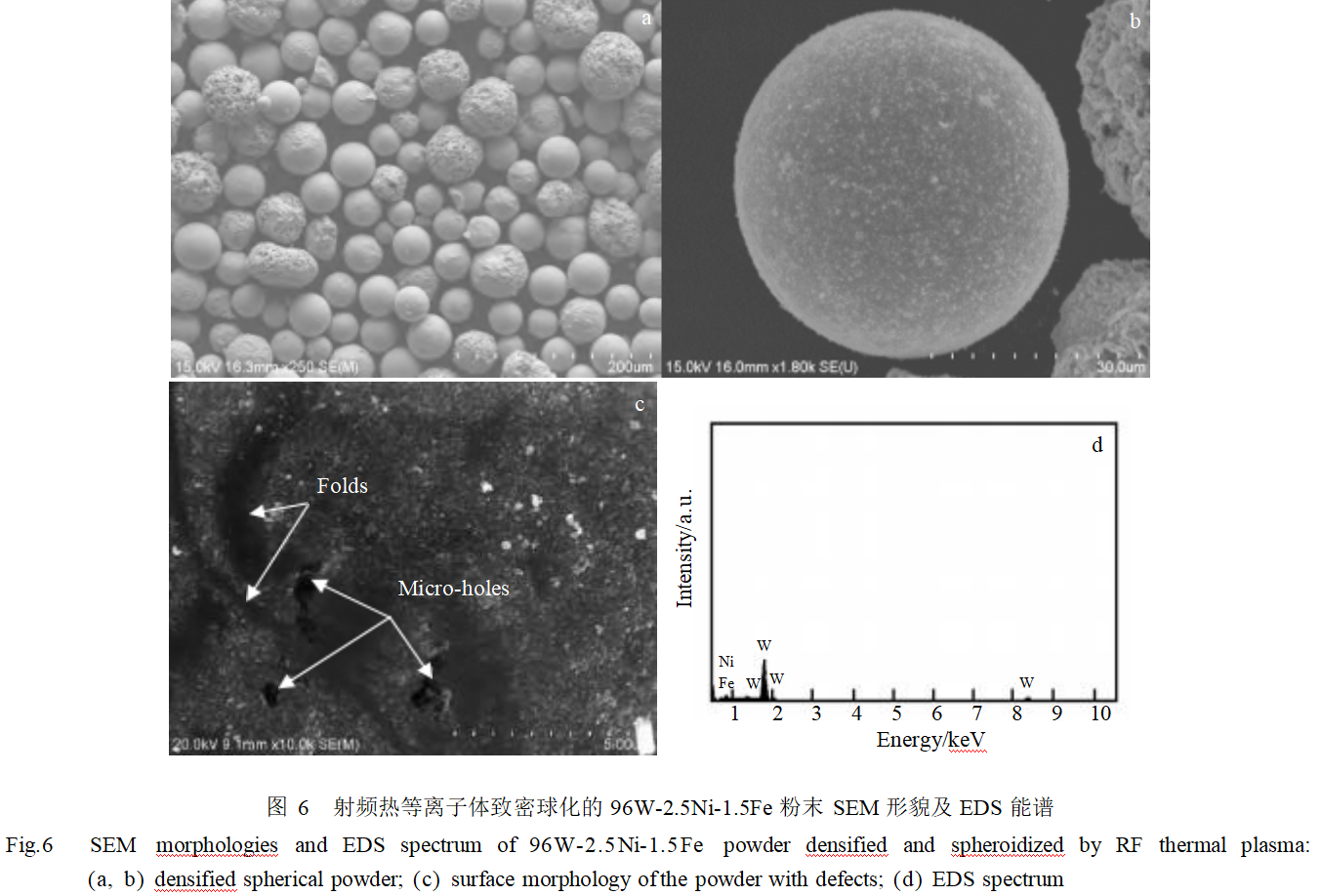

Spray-granulated 96W-2.5Ni-1.5Fe ternary alloy powder was introduced into an RF thermal plasma for treatment. Findings revealed that plasma-treated powder exhibited more regular spherical shapes, with reduced surface porosity and loosening in dense spherical particles. However, some particles remained undensified or defective, as shown in Figures 6a and 6b. Therefore, the comprehensive properties of the 96W-2.5Ni-1.5Fe ternary alloy granulated powder improved after RF thermal plasma treatment. Analysis suggests that due to the high temperature of the RF thermal plasma, intense heat exchange occurs when the powder enters the plasma flow field, causing melting. Under high temperatures, the interior and surface of the granulated powder particles rapidly melt to form droplets, which then contract into dense spherical particles under surface tension during rapid cooling.

Further examination of the surface of defective powder particles (Figure 6c) reveals micro-pores on some particle surfaces, accompanied by “wrinkles or grooves.” Analysis suggests that during the cooling and solidification of molten droplets formed by plasma melting, uneven surface tension distribution and thermal stress release occur due to differences in physical properties among elements. Alternatively, localized areas on the particle surface may not have been sufficiently heated and melted, ultimately leading to wrinkles and patterns during the cooling, contraction, and solidification process.

Furthermore, the EDS spectrum of the 96W-2.5Ni-1.5Fe powder treated with RF thermal plasma (Figure 6d) reveals that Ni and Fe phases within the particles contain high W element concentrations between W grains. This indicates the likely presence of a solid solution state between W grains, demonstrating that the high temperatures of thermal plasma can effectively fuse W, Ni, and Fe elements.

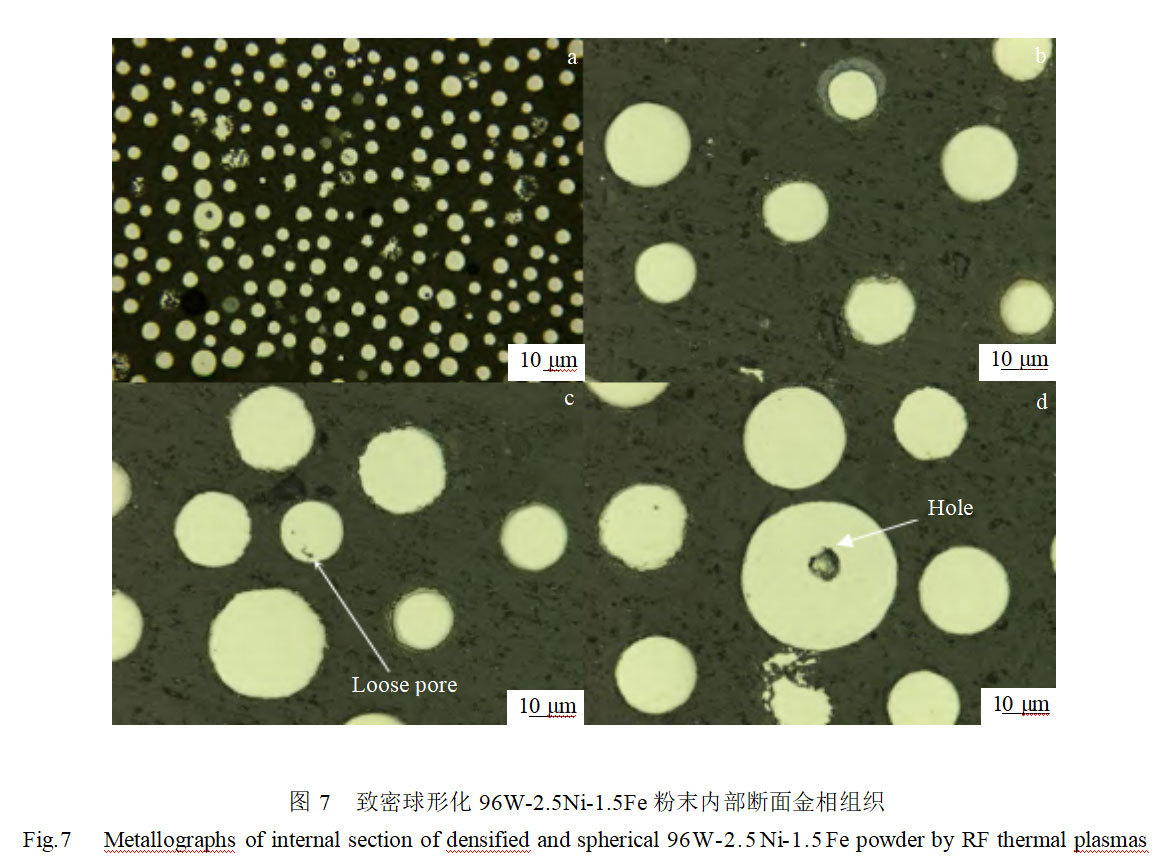

To further investigate the internal microstructure of the particles, the 96W-2.5Ni-1.5Fe ternary alloy powder treated with RF thermal plasma densification and spheroidization was polished and embedded for cross-section and internal microstructure observation. The metallographic structure of the cross-section is shown in Figure 7. The study revealed that the internal cross-sections of the particles exhibited excellent compactness and high sphericity after densification and spheroidization, with some particles containing internal voids. This phenomenon confirms that the internal regions of the 96W-2.5Ni-1.5Fe ternary alloy spray-granulated powder can achieve a favorable molten state during movement within the plasma flow field, thereby enabling densification. Concurrently, some particles still contained minor “loose pores” or “micro-voids.” as shown in Figures 7c and 7d. Analysis suggests this may result from the presence of numerous pores within the raw granulation powder. Prior to plasma exposure, these pores were filled with substantial gas volumes. Upon exposure to high plasma temperatures, the gas expanded and attempted outward release. However, due to the brief interaction time between the particles and the high-temperature plasma zone, the high-temperature gas within the particles could not be fully expelled from the droplets in time. This led to the formation of “loose pores” during the subsequent cooling and solidification process. Multiple factors contribute to residual microporosity. Analysis suggests that larger particles, due to their size, experience insufficient heat transfer with the plasma, preventing complete melting. Furthermore, theoretical calculations based on the plasma flow field distribution (Figure 4) and particle densification trajectories (Figure 5) indicate that larger particles tend to follow trajectories concentrated near the central axis, as shown in Figure 5. Combined with the plasma temperature field characteristics (Figure 4a), it is evident that larger particles, influenced by their own gravity, fail to enter the high-temperature core region of the plasma during densification and spheroidization, thus being inadequately heated. Furthermore, the insufficient heat exchange time with the plasma results in poor internal heat absorption within larger particles. Conversely, smaller particles, due to their lower self-gravity, are more readily transported by the plasma flow field into the core high-temperature zone, enabling effective melting. Generally, the melting efficiency of particles under high-temperature plasma exposure is inversely proportional to their size. Larger particles require sufficiently high temperatures and extended heating durations to achieve complete melting. Therefore, the degree of particle densification and spheroidization primarily depends on their melting extent within the plasma flow field. The particle size of the granulation powder and the movement trajectory of particles within the plasma significantly influence the heat absorption and melting efficiency, which are key factors affecting the final powder properties.

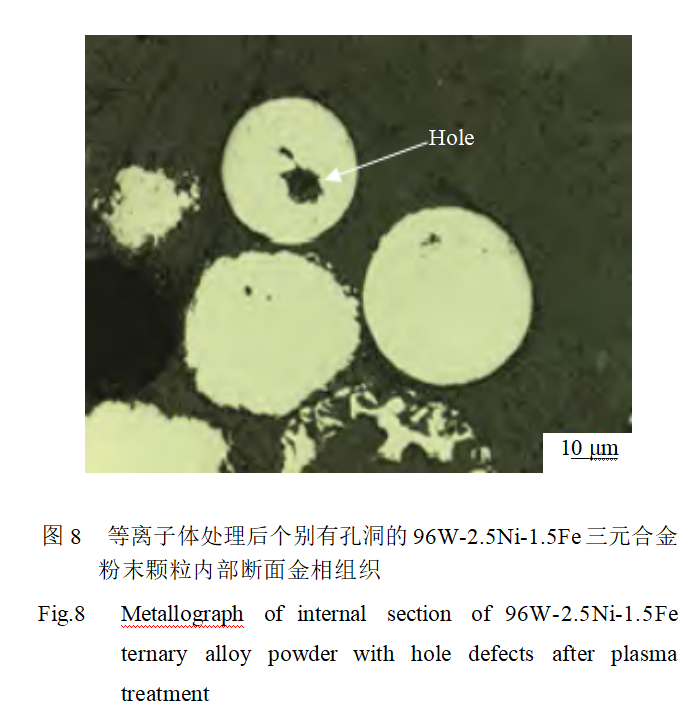

Furthermore, additional research revealed that a small number of particles treated with plasma densification and spheroidization exhibited large internal voids, indicating suboptimal densification, as shown in Figure 8. When a large number of particles enter the plasma, their trajectories follow a random process. Ensuring effective melting and densification of every particle during RF thermal plasma densification is challenging. Furthermore, differences in physical properties (such as thermal conductivity and heat transfer coefficients) arising from variations in individual particle gravity, size, and elemental composition can lead to defects like internal voids in a very small number of powder particles.

3 Conclusions

1) While spray granulation enables effective control of elemental ratios, the resulting powder particles typically exhibit loose microstructures with rough surfaces, and some may even display depressions or cracks. These characteristics adversely affect subsequent powder processing and the performance of formed components. Radiofrequency thermal plasma treatment demonstrates significant densification and spheroidization effects. Therefore, the organic integration of spray granulation with RF thermal plasma densification and spheroidization can effectively enhance the comprehensive properties of the powder.

2) The high temperature of RF thermal plasma enables solid solution formation of W, Ni, and Fe elements within the 96W-2.5Ni-1.5Fe ternary alloy powder particles, achieving effective fusion between these elements.

3) Some 96W-2.5Ni-1.5Fe ternary alloy powder particles treated with RF thermal plasma densification and spheroidization exhibit “wrinkles and micro-pores” on their surfaces. This phenomenon may result from uneven surface tension distribution due to differences in physical properties between elements, thermal stress release during the cooling and solidification of molten droplets, and insufficient heat transfer between larger particles and the plasma. micro-pores" on the surface of some 96W-2.5Ni-1.5Fe ternary alloy powder particles. This phenomenon may be attributed to multiple factors, including uneven surface tension distribution due to differences in physical properties among the elements, thermal stress release during the cooling and solidification of molten droplets, insufficient heat transfer between larger particles and the plasma, or uneven release of residual gases within internal voids of the granulated powder.

Reference: Chinese Library Classification: TF123; TG146.4+11 Document Code: A Article ID: 1002-185X(2023)10-3563-08

Spray Granulation Pre-Alloying of W-Ni-Fe Ternary Alloy Powder and RF Hot Plasma-Induced Densification and Sphericalization Study

Stardust Technology employs radiofrequency plasma spheroidization technology to produce spherical tungsten-nickel-iron (W-Ni-Fe) alloy powder characterized by high purity, high sphericity, smooth surface finish, absence of satellite particles, and uniform particle size distribution. These properties confer excellent flowability and high packing density. This powder material typically exhibits favorable mechanical properties and high density, making it suitable for powder metallurgy processes in high-density alloy production (e.g., aerospace counterweights, radiation shielding components), 3D printing (additive manufacturing), and injection molding applications. For further details, please contact our specialist: Cathie Zheng at +86 13318326187.

News