2000℃ high temperature and high load Ta-W refractory alloy

Release time:

2025-09-16

Ultra-high temperature materials refer to heat-resistant cutting-edge materials that can still be used normally in harsh environments such as stress, oxidation, and ablation, as well as in ultra-high temperature conditions of about 2000℃ and above. For example, in the field of materials science, from the perspective of service environment temperature, high-temperature high-entropy alloys that still have a strength of more than 200 MPa at 1800℃ are called ultra-high temperature high-entropy alloys[1]. With the development of aerospace technology, some structural components have put forward more stringent requirements on the high-temperature resistance of materials. For example, when a supersonic aircraft flies in a dense atmosphere, the temperature of the front end of the aircraft will rise sharply with the increase of flight speed. When the flight speed reaches 8 Ma, the temperature of the nose cone will rise to nearly 2000℃[2]. For example, for turbine blades of engines with a thrust-to-weight ratio of up to 15~20, their operating temperature is close to 1900℃. The melting point of traditional nickel-based single crystal high-temperature alloys is 1400~1500℃, which can no longer meet service requirements[3]. For traditional refractory alloys, such as tungsten alloys and molybdenum alloys, although they have high melting points, their tensile strength at 2000℃ is less than 100 MPa[4]. Therefore, there is an urgent need to find and develop new ultra-high temperature materials that can maintain high strength at high temperatures to meet the service requirements in extreme environments; at the same time, they have good forming ability at room temperature to meet the processing requirements of complex and precise structures. It is well known that there is an intrinsic inverse relationship between the strength and plasticity of metal materials, that is, the increase in material strength is often accompanied by a decrease in plasticity or toughness, and the two generally show an inverse constraint relationship of one increasing while the other decreases. Before the softening behavior of the material occurs, this inverse relationship is widely present from room temperature to high temperature. Therefore, for traditional metal materials, synergistically improving the strength and plasticity of materials has always been a hot topic and difficult problem in the field of materials science. Ultra-high temperature materials face a greater challenge: how to maintain excellent mechanical properties at high temperatures while also taking into account excellent room temperature plasticity and processing forming capabilities. Compared with the inverse relationship between strength and plasticity at room temperature, these two are more difficult to coordinate. In recent years, refractory high entropy alloys with bcc structure have attracted widespread attention in the materials community. They are composed of a mixture of multiple refractory elements in equiatomic or near-equiatomic ratios [5-8]. Some bcc structure refractory high entropy alloys exhibit high strength in the high temperature range, even better than traditional nickel-based high-temperature alloys. For example, the compressive yield strength of equiatomic ratio NbMoTaW and NbMoTaWV high entropy alloys at 1600℃ is as high as 405 and 477 MPa respectively [9], and HfNbTaTiZr high entropy alloy has a yield strength of 92 MPa at 1200℃ [10]. Although refractory high entropy alloys exhibit excellent high temperature strength, they still face two major problems in their future use: On the one hand, most refractory high entropy alloys exhibit severe brittleness at room temperature. For example, the room temperature compressive fracture strain of NbMoTaW high entropy alloy is less than 3%, which brings great difficulties to the room temperature forming of the material. Although the room temperature compressive plasticity of NbMoTaW high entropy alloys can be improved to a certain extent by introducing alloying elements (such as Ti[11], Zr[12]) or adding light elements such as B and C[13], this also increases the complexity of alloy design and the difficulty of batch melting and processing. On the other hand, alloy materials usually soften when the temperature is higher than (0.5~0.6)Tm (Tm is the melting point), that is, the strength drops sharply. Refractory high entropy alloys have a large number of main elements. In order to improve their room temperature plasticity, they often contain elements with relatively low melting points, such as Ti (1660℃) and Zr (1852℃). However, the potential softening behavior of the material at ultra-high temperatures of 2000℃ and above cannot be avoided. Recent studies [14] have shown that the introduction of eutectic carbides into a refractory high-entropy alloy matrix can significantly improve the high-temperature strength of the material. The prepared Re0.5MoNbW(TaC)x alloy has a compressive yield strength of 1.08 GPa at 1200°C and a compressive plasticity of 8.5% at room temperature, which provides a new idea for the design of ultra-high-temperature refractory high-entropy alloys.

In response to the above problems, this work selected a Ta-W alloy with Ta as the matrix and W added. The advantages of this system are mainly reflected in the following three aspects: First, the melting points of Ta and W are 2996 and 3410°C, respectively. The substitutional continuous solid solution alloy formed by the two has a high melting point of more than 3000°C, and is expected to maintain considerable compressive strength at ultra-high temperatures. Early commercial Ta-W alloys developed contained relatively low W contents, typically not exceeding 15% (atomic fraction, the same below), resulting in relatively low high-temperature strength [15,16]. For example, the tensile strength of the Ta-10W alloy at 2000°C was only around 100 MPa [17,18]. While increasing the W content appropriately is expected to further improve high-temperature mechanical properties, this may result in a significant decrease in room-temperature plasticity [15,16]. Furthermore, Ta has a ductile-brittle transition temperature far below room temperature. Compared to refractory high-entropy alloys, which typically require more than four main component ratios, the Ta-W binary system is simpler and has a relatively mature melting and hot working forming process as a reference. This reduces the complexity of searching for alloy compositions and preparation in a multidimensional compositional space, enabling alloys with superior mechanical properties to be obtained in a shorter time and at a lower cost. Based on the above considerations, this work designed and prepared Ta-W alloys with W contents of 10%, 20%, 30%, 40%, and 50%. The room temperature and 2000°C high-temperature compression properties of this alloy system were tested to evaluate its potential in terms of high-temperature strength and room-temperature ductility.

1 Experimental Methods

1.1 Sample Preparation

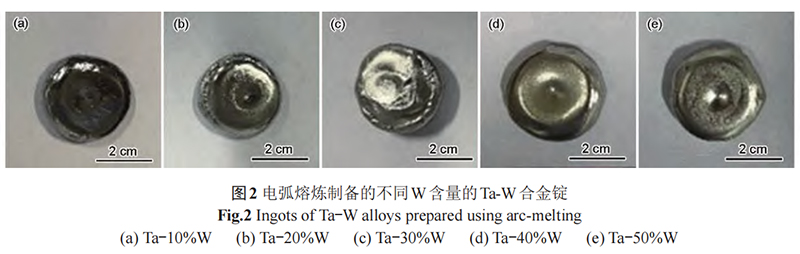

The raw materials for preparing the Ta-W alloys were high-purity W ingots (99.9%) and Ta ingots (99.9%). The raw materials were melted by arc melting under an Ar gas protective atmosphere. Each alloy sample was repeatedly turned over 10 times under electromagnetic stirring to ensure compositional homogeneity. Ta-W alloys with different W contents were produced: Ta-10%, Ta-20%, Ta-30%, Ta-40%, and Ta-50%. After melting, the ingots were homogenized at 600°C for 15 h.

1.2 Microstructure Characterization

To observe the alloy microstructure, the specimens were mechanically polished and then electropolished. The electrolyte composition was H₂SO₄:HF:C₂H₅OH = 7:3:4 by volume, with a voltage and current of 30 V and 0.6 A, respectively. The phase composition of the Ta-W alloy was analyzed using a D8 ADCANCE X-ray diffractometer (XRD) equipped with a Cu target, with a scanning angle of 10°–120° and a scanning rate of 0.2°/s. The alloy microstructure was observed using an EVO 10 scanning electron microscope (SEM) equipped with an energy dispersive spectrometer (EDS) probe. The average grain size was determined using Image J software.

1.3 Mechanical Properties

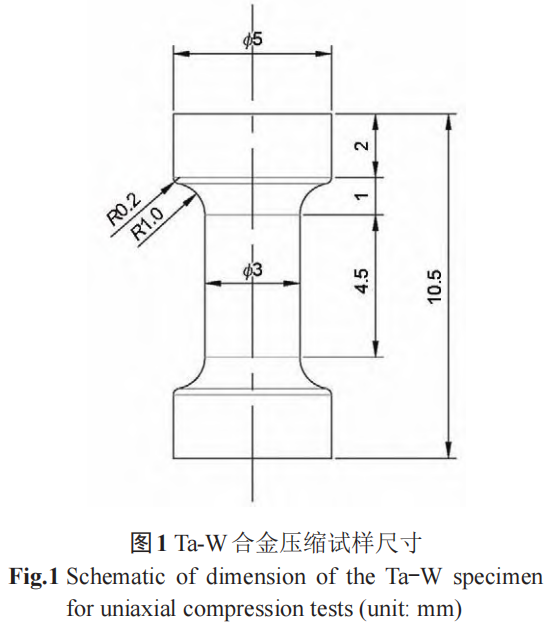

To ensure stability during compression testing, dumbbell-shaped specimens with a gauge length of 3 mm diameter × 4.5 mm were used, as shown in Figure 1. The room-temperature compression properties of the alloys were tested using an Instron 5969 electronic universal testing machine at a strain rate of 3 × 10⁻⁴ s⁻¹. High-temperature compression properties were tested using a ZwickRoell Kappa creep tester. The samples were placed in a vacuum furnace, evacuated to below 1 Pa, and then purged with Ar gas. The temperature was raised using radiative heating at an average rate of approximately 35°C/min. After reaching the target temperature, the temperature was held for 10 minutes before compression testing at a strain rate of approximately 10⁻⁴ s⁻¹. At least two samples of each alloy composition were tested to ensure the validity of the test results. 2 Experimental Results

2 Experimental Results

2.1 Alloy Samples and Phase Composition

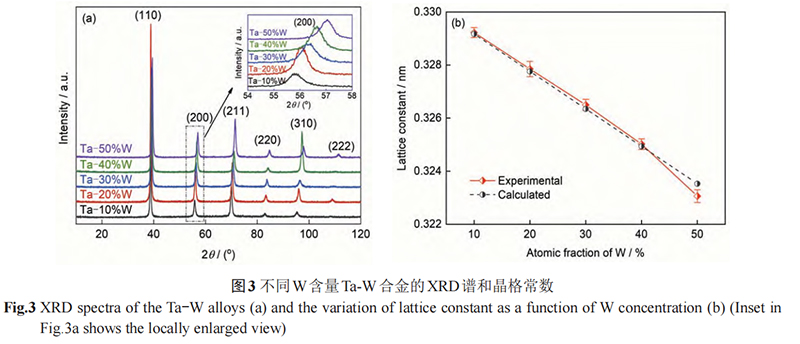

Figure 2 shows arc-melted and annealed Ta-W alloy ingots with different W contents. The samples exhibit a bright and smooth surface, free of surface cracks and pores. Figure 3a shows the XRD spectra of Ta-W alloys with different W contents. This series of alloys demonstrates a single-phase microstructure with a bcc structure. As the W content increases, the diffraction peak gradually shifts to a higher angle. The lattice constants of different alloy samples were obtained based on the XRD results, as shown in Figure 3b. It can be seen that as the W content increases, the lattice constant of the alloy gradually decreases. The lattice constants of the samples with W contents of 10%, 20%, 30%, 40% and 50% are 0.3292, 0.3279, 0.3265, 0.3250 and 0.3231 nm, respectively. For Hume-Rothery solid solutions [19-21], the theoretical lattice constant (amix) of the alloy can be estimated using Vegard's law [20]:

Where ai and ci are the lattice constant and atomic concentration of elemental metal i, respectively. The calculated theoretical lattice constants of the five Ta-W solid solutions are consistent with the experimental results, as shown in Figure 3b. Figure 3 shows that Ta and W elements are fully mixed at the atomic scale.

2.2 Microstructure

2.2 Microstructure

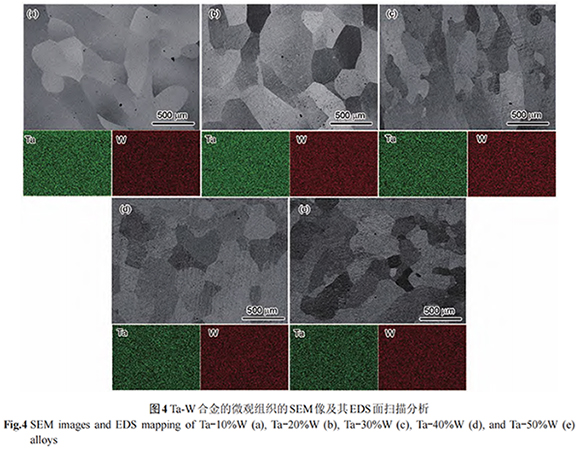

SEM images and EDS scans of the microstructure of Ta-W alloys with different W contents are shown in Figure 4. The Ta-W alloys are primarily equiaxed, with a small number of grains exhibiting coarse columnar morphology. Grain size decreases significantly with increasing W content, with average grain sizes of 427, 313, 276, 255, and 190 μm for the Ta-10%W, Ta-20%W, Ta-30%W, Ta-40%W, and Ta-50%W alloys, respectively. EDS analysis of the Ta and W elemental distribution in the alloys revealed no secondary phases or microsegregation, indicating that the alloys form a single-phase solid solution structure with homogeneous interdissolution of Ta and W.

2.3 Compressive Properties at Room and High Temperatures

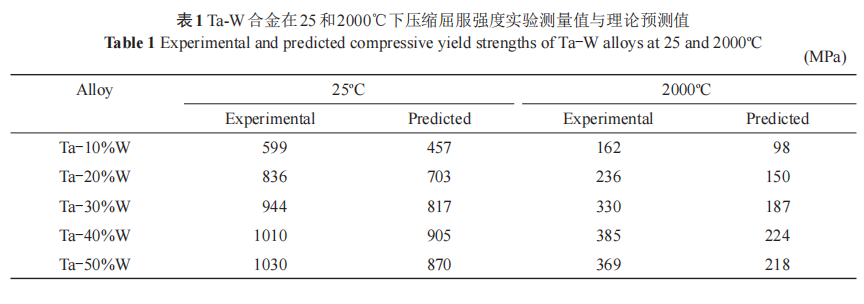

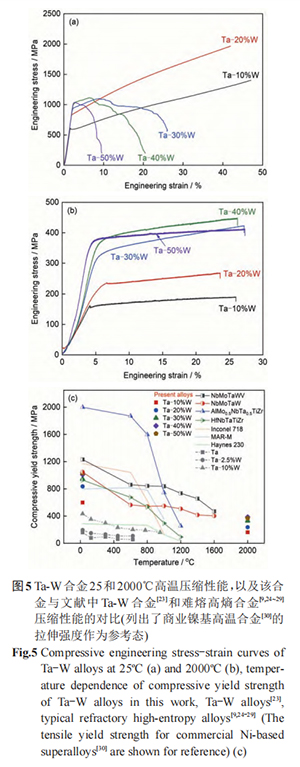

Figure 5a shows the engineering stress-strain curves of Ta-W alloys with different W contents subjected to room temperature compression. It can be seen that the room-temperature compressive strength of Ta-W alloys gradually increases with increasing W content. The yield strengths of the Ta-10%W and Ta-20%W alloys reach 599 and 836 MPa, respectively. Further increases in W content do not significantly increase the yield strength of the samples, reaching 1030 MPa for Ta-30%W and Ta-40%W (Table 1). The compressive plasticity of Ta-W alloys is also closely related to W content. For the Ta-10%W and Ta-20%W alloys, the samples do not fracture even when the compressive strain exceeds 40%, demonstrating good room-temperature compressive plasticity. However, with further increases in W content, the compressive fracture strain decreases significantly, particularly for the Ta-40%W and Ta-50%W alloys.

Figure 5b shows the engineering stress-strain curves of Ta-W alloys with different W contents compressed at 2000°C. It can be seen that as the W content increases from 10% to 50%, the compressive yield strength of the alloy is 162, 236, 330, 385 and 369 MPa respectively (Table 1). All alloys with different W contents have good compressive plasticity at high temperature, and the samples do not break when the compressive strain exceeds 20%. In addition, under the influence of temperature and stress, the grains of the alloy grow significantly after high-temperature compression deformation. Taking Ta-20%W as an example, its average grain size increases from the initial 313 μm to 580 μm after deformation.

As can be seen from Table 1, the increase in W content can effectively improve the strength of Ta-W alloy. When the W content exceeds 20%, the increase in room temperature and high temperature strength is relatively limited. The tensile properties of Ta-W alloy are only available for Ta-10%W, and its room temperature tensile yield strength is 471 MPa[22], which is 128 MPa lower than the compressive strength tested in this work, indicating that Ta-W alloy may exhibit a certain tensile and compressive asymmetry.

Figure 5c compares the compressive (tensile) yield strength of the Ta-W alloy in this work and the Ta-W alloy in the literature [23] with the existing major refractory high entropy alloys [9, 24-29] and nickel-based superalloys [30] at different temperatures. It can be seen that commercial nickel-based superalloys lose their strength at temperatures exceeding 1200°C and cannot meet the service requirements of higher temperatures. Due to the large number of refractory high entropy alloy systems currently under development, this work only selects several typical refractory high entropy alloys for comparison, including AlMo0.5NbTa0.5TiZr with the highest room temperature strength [29], HfNbTaTiZr with good room temperature plasticity [28], and NbMoTaW(V) with the highest high temperature strength [9]. Most refractory high-entropy alloys, such as AlMo0.5NbTa0.5TiZr and HfNbTaTiZr, have yield strengths below 200 MPa at 1300°C. Only NbMoTaW and NbMoTaWV alloys maintain high high-temperature compressive strength, exceeding 400 MPa at 1600°C. In contrast, the Ta-W alloys developed in this study exhibit superior high-temperature mechanical properties, maintaining a compressive strength exceeding 200 MPa at 2000°C. This is expected to rival or even exceed the currently top-performing high-temperature refractory high-entropy alloy, NbMoTaW(V) (its performance at 2000°C and above has not yet been reported). Furthermore, unlike the room-temperature compressive plasticity of less than 3% for refractory high-entropy alloys, the Ta-W alloys developed in this study exhibit comparable room-temperature processability. For example, the Ta-20%W alloy can withstand compressive strains exceeding 40% at room temperature and is machinable (see Figure 5a).

3 Analysis and Discussion

As shown above, the addition of W can effectively improve the compressive strength of Ta-W alloy at room temperature and high temperature. The strengthening mechanism of Ta-W alloy is analyzed below to reveal the influence of W on the compressive strength of Ta-W alloy.

3.1 Grain boundary strengthening mechanism

As shown in Figure 4, W can play a role in refining the grains of Ta-W alloy. The contribution of grain boundary strengthening to yield strength (σd) can be calculated using the Hall-Petch formula [31] as follows:

Where, k is the Hall-Petch coefficient, which is 14 MPa·mm1/2 [32]; d is the average grain size. According to the grain sizes of different Ta-W alloys obtained as shown in Figure 4, it is found that as the W content increases from 10% to 50%, σd is only 21.4, 25.0, 26.6, 27.7 and 32.1 MPa, respectively. This shows that due to the coarse grain size, the contribution of grain boundary strengthening to the strength of the five alloys is extremely limited, and grain boundary strengthening is not the main strengthening mechanism of Ta-W alloys.

3.2 Solid solution strengthening mechanism

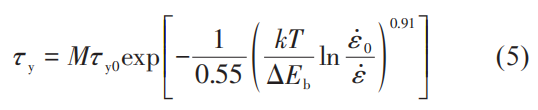

In addition to grain boundary strengthening, another strengthening mechanism is solid solution strengthening. The solid solution strengthening model based on dislocation theory [33-35] is used to predict the strength of different Ta components.Yield strength of Ta-W alloy. The model assumes that a single solute atom interacts elastically with the dislocations in the alloy. For an alloy containing n elements with a concentration of cn, the non-thermally activated shear yield stress (τy0) and energy barrier (ΔEb) at temperature 0 K are [34]: Where G and ν represent the shear modulus and Poisson ratio, respectively, α = 1/12 is the weighting coefficient of the dislocation line tension in the bcc structure lattice, b is the Burgers vector modulus, and ΔVn is the atomic mismatch volume of element n [36]. At temperature T and strain rate ε, the theoretically predicted yield stress (τy) is [34]:

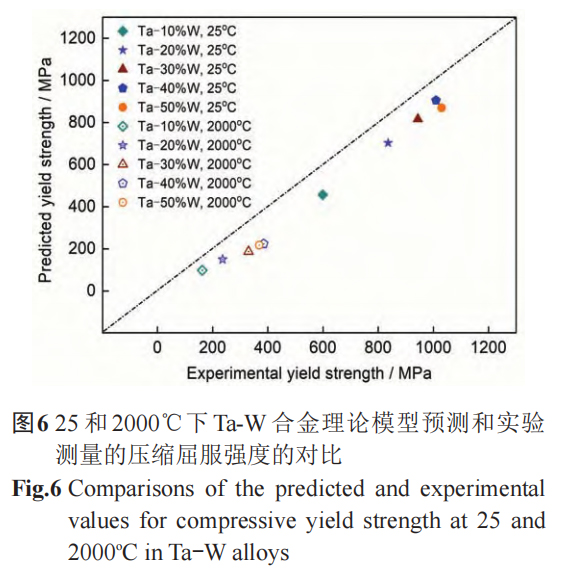

Where G and ν represent the shear modulus and Poisson ratio, respectively, α = 1/12 is the weighting coefficient of the dislocation line tension in the bcc structure lattice, b is the Burgers vector modulus, and ΔVn is the atomic mismatch volume of element n [36]. At temperature T and strain rate ε, the theoretically predicted yield stress (τy) is [34]: Where ε0 = 104 s-1 is the reference strain rate, and M (= 3.06) is the Taylor coefficient of polycrystalline strength. Table 1 gives the theoretical predicted values of the compressive yield strength of Ta-W alloy at 25 and 2000℃. Figure 6 compares the compressive yield strengths of theoretical predictions and actual tests. The dotted line is the reference line where the theoretical and experimental tests are equal. The experimental test values below the dotted line are greater than the theoretical predictions, whereas the measured values above the dotted line are less than the theoretical predictions. It can be seen that at temperatures of 25 and 2000 °C, the theoretically predicted compressive yield strength of the alloy increases with increasing W content, and this prediction trend is consistent with the experimental test. Moreover, as the W content increases to more than 20%, the improvement in alloy strength predicted by the model is not significant, which is consistent with the experimental observations. It is worth noting that the yield strength predicted by the theoretical model is about 100 MPa lower than the experimental value. This may be due to the following two reasons: On the one hand, the model mainly considers the contribution of solid solution effect to strength based on dislocation theory, and assumes that screw dislocations are not affected by kink nucleation, similar to edge dislocation slip. This is applicable to high entropy alloys because localized large lattice distortion in high entropy alloys can induce spontaneous nucleation of kinks on screw dislocation lines [37]. However, for the Ta-W binary alloy in this work, since the sizes of Ta and W are close, it is not easy for the spontaneous nucleation of kinks to occur. Therefore, similar to traditional bcc alloys, additional stress is required to induce the nucleation of kinks. On the other hand, there are trace amounts of impurities such as O, N, and C in the Ta-W alloy melted in the experiment. For example, for commercial Ta-10%W, its room temperature compressive strength is comparable to that of the sample in this work. Chemical analysis shows that the main impurities O, N, and C in the commercial alloy are 20 × 10-6, 37 × 10-6, and 6 × 10-6 by mass, respectively. These impurity elements tend to be segregated around dislocations, exerting a certain pinning effect on dislocations, and thus may produce additional strengthening effects [13].

Where ε0 = 104 s-1 is the reference strain rate, and M (= 3.06) is the Taylor coefficient of polycrystalline strength. Table 1 gives the theoretical predicted values of the compressive yield strength of Ta-W alloy at 25 and 2000℃. Figure 6 compares the compressive yield strengths of theoretical predictions and actual tests. The dotted line is the reference line where the theoretical and experimental tests are equal. The experimental test values below the dotted line are greater than the theoretical predictions, whereas the measured values above the dotted line are less than the theoretical predictions. It can be seen that at temperatures of 25 and 2000 °C, the theoretically predicted compressive yield strength of the alloy increases with increasing W content, and this prediction trend is consistent with the experimental test. Moreover, as the W content increases to more than 20%, the improvement in alloy strength predicted by the model is not significant, which is consistent with the experimental observations. It is worth noting that the yield strength predicted by the theoretical model is about 100 MPa lower than the experimental value. This may be due to the following two reasons: On the one hand, the model mainly considers the contribution of solid solution effect to strength based on dislocation theory, and assumes that screw dislocations are not affected by kink nucleation, similar to edge dislocation slip. This is applicable to high entropy alloys because localized large lattice distortion in high entropy alloys can induce spontaneous nucleation of kinks on screw dislocation lines [37]. However, for the Ta-W binary alloy in this work, since the sizes of Ta and W are close, it is not easy for the spontaneous nucleation of kinks to occur. Therefore, similar to traditional bcc alloys, additional stress is required to induce the nucleation of kinks. On the other hand, there are trace amounts of impurities such as O, N, and C in the Ta-W alloy melted in the experiment. For example, for commercial Ta-10%W, its room temperature compressive strength is comparable to that of the sample in this work. Chemical analysis shows that the main impurities O, N, and C in the commercial alloy are 20 × 10-6, 37 × 10-6, and 6 × 10-6 by mass, respectively. These impurity elements tend to be segregated around dislocations, exerting a certain pinning effect on dislocations, and thus may produce additional strengthening effects [13].

4 Conclusion

4 Conclusion

In this work, a series of Ta-W alloys (W content of 10%~50%) were designed and prepared by arc melting. The alloy is a single-phase bcc structure solid solution. With the increase of W content, the lattice constant and grain size of the Ta-W alloy gradually decrease. Increasing the W content significantly improves the room-temperature and high-temperature compressive strength of Ta-W alloys. The compressive yield strength of a Ta-20%W alloy at 2000°C exceeds 200 MPa, and it exhibits excellent room-temperature compressive plasticity and formability. This alloy system is expected to serve as a new generation of ultra-high-temperature load-bearing materials for the manufacture of critical load-bearing and high-temperature resistant aerospace components.

Article Citation Information

Acta Metallurgica Sinica, Volume 58, Issue 10, October 2022

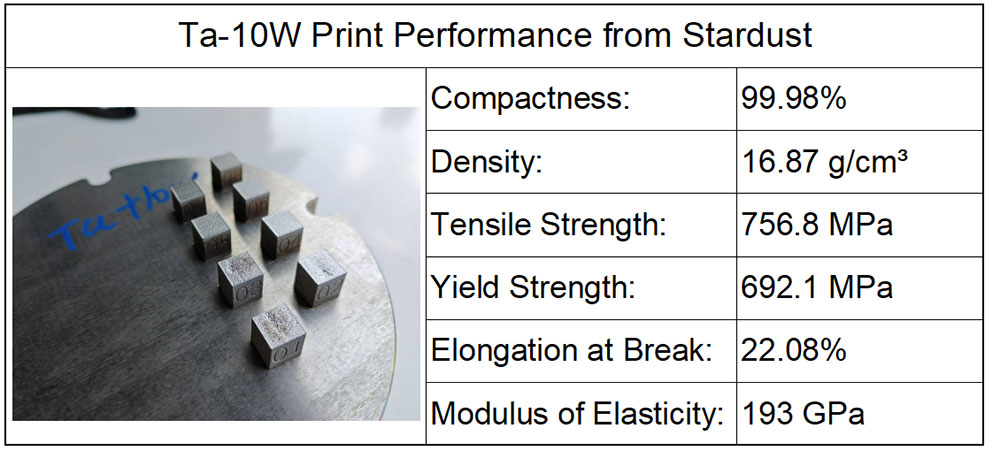

Tantalum-tungsten alloy is a high-density material characterized by a high melting point, high tensile strength, excellent dynamic ductility, and corrosion resistance. It is used in chemical corrosion protection, machinery, aerospace, and military applications.Stardust Technology's spherical Ta-10W alloy powder is produced using a radio frequency plasma spheroidization process. It features high purity, low oxygen content, high sphericity, a smooth surface, no satellites, uniform particle size distribution, excellent flowability, and high bulk and tap densities.

http://en.stardusttech.cn/products/49.html

For more refractory metal spherical powder products, please contact Vicky Zhang at +86-13318326185

For more refractory metal spherical powder products, please contact Vicky Zhang at +86-13318326185

News