-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

PRODUCTS

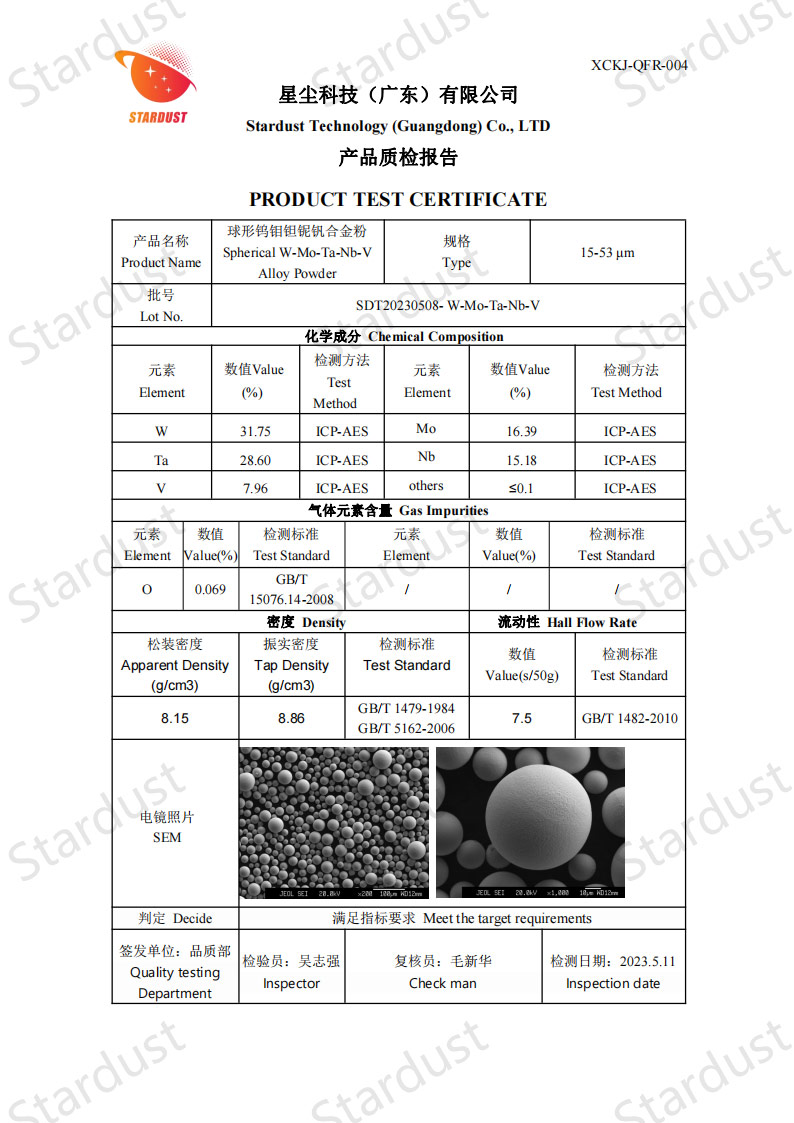

Spherical W-Mo-Ta-Nb-V high entropy alloy powder 20-63μm

产品型号:

Product Features

Classification:Metal Powders

Keywords: tantalum powder, tungsten powder

Product details

Spherical W-Mo-Ta-Nb-V alloy powder is an alloy powder composed of tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V). It mainly has excellent high temperature performance, strength and corrosion resistance, and is widely used in industries that require high temperature, wear resistance and corrosion resistance.

1. Characteristics:

- High melting point and thermal stability: Tungsten (W), molybdenum (Mo), rhenium (Ta), niobium (Nb) and vanadium (V) in the alloy are all high melting point elements with excellent thermal stability, which enables the alloy to maintain good mechanical properties under extremely high temperature environment.

- High strength and hardness: The tensile strength, hardness and compressive strength of the alloy powder are very high, especially suitable for applications requiring high load and high wear resistance.

- Corrosion resistance: Elements such as molybdenum, rhenium, niobium and vanadium enhance the oxidation resistance and corrosion resistance of the alloy, especially in extreme environments such as high temperature, acid and alkali.

- Excellent thermal and electrical conductivity: Tungsten has excellent thermal and electrical conductivity, so W-Mo-Ta-Nb-V alloy powder is widely used in environments that require good thermal or electrical conductivity.

- Good machinability: The addition of vanadium can improve the machinability of the alloy, allowing the alloy to maintain good machinability at high temperatures.

2. Application areas:

- Aerospace and high-temperature alloy materials: The alloy is often used in jet engines, rocket propulsion systems, aircraft parts in high-temperature environments, etc. The high strength and high-temperature stability of the alloy make it essential in high-performance engines.

- Nuclear energy and radiation protection: Due to the high density of tungsten and the high-temperature resistance of the alloy, W-Mo-Ta-Nb-V alloy is widely used in the nuclear energy industry and radiation protection equipment, such as radiation shielding materials, nuclear reactor components, etc.

- High-temperature electronic components: The elements such as tungsten and molybdenum in the alloy have excellent conductivity and thermal stability, so they can be used in high-power electronic equipment, electronic components, vacuum electronic devices and high-temperature electrodes.

- High temperature tools and wear-resistant materials: Alloy powder can be used to manufacture wear-resistant tools, high temperature cutting tools and other high temperature and wear-resistant industrial parts.

- Metallurgical and petrochemical equipment: Due to its excellent corrosion resistance and wear resistance, the alloy is also used in metallurgical industry and petrochemical equipment, especially those parts that need to operate in harsh environments.

3. Preparation method:

- Radio frequency plasma spheroidization

Related products

-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Stardust Technology (Guangdong) Co., Ltd.

101, Building 1, Liandong Youzhi Zone, Senshuji Road, Nansha Community, Danzao Town, Nanhai District, Foshan City,Guangdong Pro.,China

QR code