-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

PRODUCTS

Spherical Refractory Ni-Ti Powder 15-53µm

产品型号:

Product Features

Classification:Metal Powders

Keywords: tantalum powder, tungsten powder

Product details

Stardust company provide Ni-Ti powder has outstanding biocompatibility, high specific strength and excellent mechanical properties, and is widely used in biomedical, aerospace, 3C electronics and other fields. Radio-frequency plasma spherical titanium powder have high purity, high sphericity , no satellite spheres, excellent flow properties, and high bulk density, no hollow particle etc charateristics. Suitable for 3D printing, hot isostatic pressing, ejection molding, and other processes.

We can not only provide relatively mature research on pure Ni-Ti spherical powder but also provide 3D printing services, metal spheroidization services, 3D printing machines and devices .

- Spherical Refractory Ni-Ti Powder Particle Size

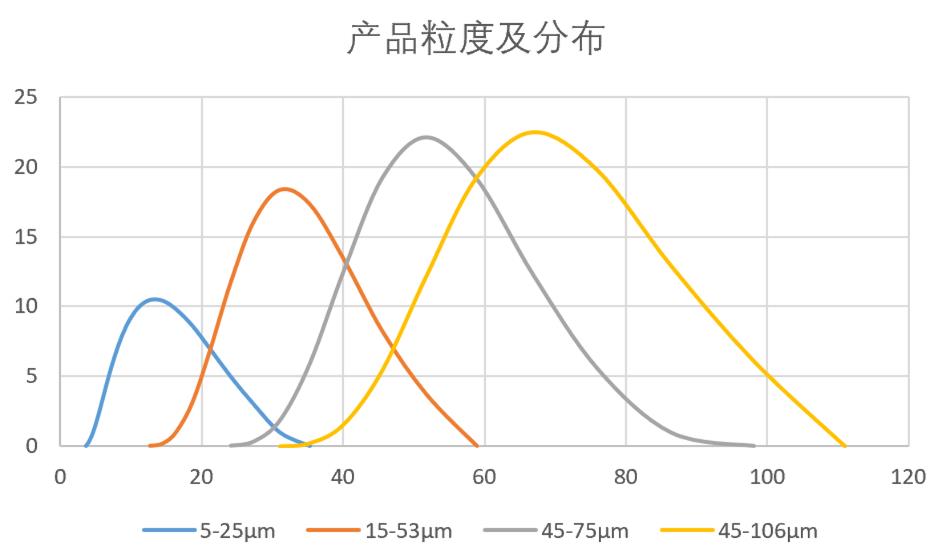

5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm.

(Various granularities can be customized according to customer requirements)

- Particle Size Distribution Graphic

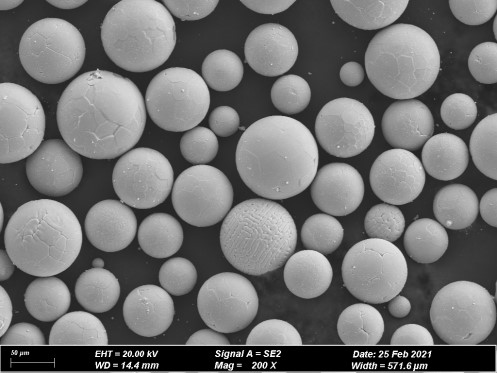

- Spherical Refractory Ni-Ti Powder Characteristics

High purity (≥99.9%), low oxygen (≤300ppm), high sphericity (≥98%), smooth surface, no satellite spheres, uniform particle size distribution, and excellent flow properties (≤25.0s/50g), And high bulk density (≥2.1g/cm³) and tap density (≥2.8g/cm³).

- Spherical Refractory Ni-Ti Powder Applicable Progress

- Laser/electron beam additive manufacturing (SLM/EBM, 3D printing)

- Laser direct deposition (DLD)

- Powder hot isostatic pressing (HIP)

- Metal injection molding (MIM)

- Powder metallurgy (PM)

- Laser cladding ( LC), and other processes.

- Spherical Refractory Ni-Ti Powder Packaging

Vacuum packaging, 1kg/bag, 2kg/bag; iron drum lined with plastic bag 25 kg/drum; special packaging is available according to user requirements.

- Chemical Composition

| Chemical Composition | |||||

| Element | Value (%) | Test Method | Element | Value (%) | Test Method |

| Ni | ≥99.9 | — | As | <0.001 | ICP-AES |

| Fe | <0.01 | ICP-AES | Ti | <0.001 | ICP-AES |

| Si | <0.008 | ICP-AES | W | <0.001 | ICP-AES |

| Al | <0.006 | ICP-AES | Other | <0.05 | ICP-AES |

| Gas Impurities | |||||

| Element | Value (%) | Test Standard | Element | Value (%) | Test Standard |

| C | 0.004 | GB/T 4324-2012 | O | 0.042 | GB/T 4324-2012 |

- Physical Property

| Density (g/cm3) | Hall Flow Rate (s/50g) | |||

| Apparent Density | Tap Density | Test Standard | Value | Test Standard |

| 4.2 | 5.41 | GB/T 1479-1984 GB/T 5162-2006 |

16.50 | GB/T 1482-2010 |

- Appearance

Related products

-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Stardust Technology (Guangdong) Co., Ltd.

101, Building 1, Liandong Youzhi Zone, Senshuji Road, Nansha Community, Danzao Town, Nanhai District, Foshan City,Guangdong Pro.,China

QR code