-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

PRODUCTS

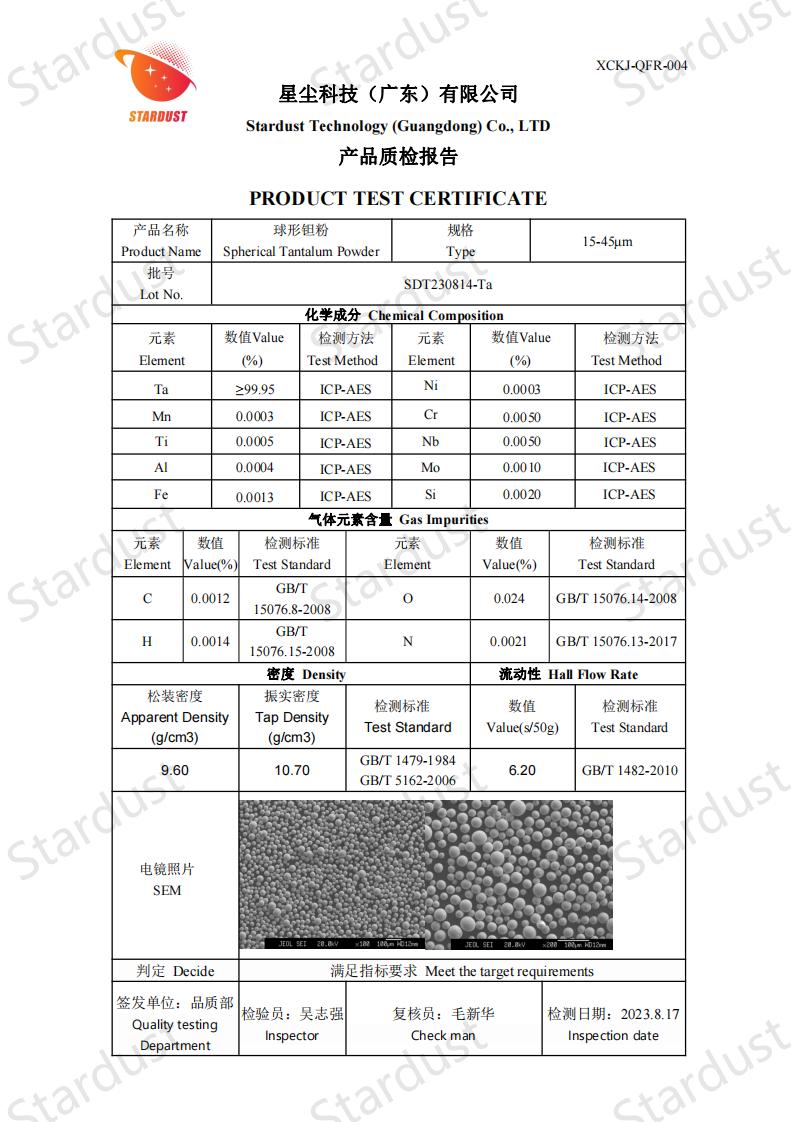

Spherical Tantalum Powder 15-45µm

产品型号:

Product Features

Classification:Metal Powders

Keywords: tantalum powder, tungsten powder

Product details

Powder properties

Shape: The sphericity is high, most of the particles are regular spherical, the surface is smooth, the friction and agglomeration between particles are reduced, and processing is convenient.

Particle size: The particle size distribution is relatively narrow, and products with different particle size ranges can be prepared according to demand, generally at the micron level, which can meet a variety of application scenarios.

Purity: There are few impurities mixed in the preparation process, the purity is good, and the content of impurity elements (such as oxygen, carbon, nitrogen, etc.) is effectively reduced, ensuring the quality and performance stability of tantalum powder.

Density: The bulk density and tap density are high, and the stacking is tight, which provides a good foundation for the subsequent molding process and helps to improve the density of the product.

Flowability: The good spherical shape gives it excellent flowability. In the storage, transportation and processing links, it can smoothly carry out transportation, filling and other operations, and improve production efficiency.

Application field

Electronic field: Used to manufacture tantalum electrolytic capacitors, widely used in mobile phones, computers, tablets and other electronic products, to ensure stable operation of circuits and improve equipment performance.

Aerospace: The production of high-temperature parts of aircraft engines, such as combustion chambers, turbine blades, etc., uses tantalum's high melting point and high-temperature strength to adapt to extreme working conditions.

Medical devices: The production of orthopedic implants, such as bone nails and bone plates, can promote bone healing due to its good biocompatibility; it can also be used as a coating material to improve the surface performance of medical devices.

Chemical industry: The production of corrosion-resistant reactors, pipelines and other equipment parts, relying on the corrosion resistance of tantalum to resist the erosion of strong acids, strong alkalis and other chemical substances.

Preparation process

RF plasma spheroidization

Related products

-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Stardust Technology (Guangdong) Co., Ltd.

101, Building 1, Liandong Youzhi Zone, Senshuji Road, Nansha Community, Danzao Town, Nanhai District, Foshan City,Guangdong Pro.,China

QR code