-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

PRODUCTS

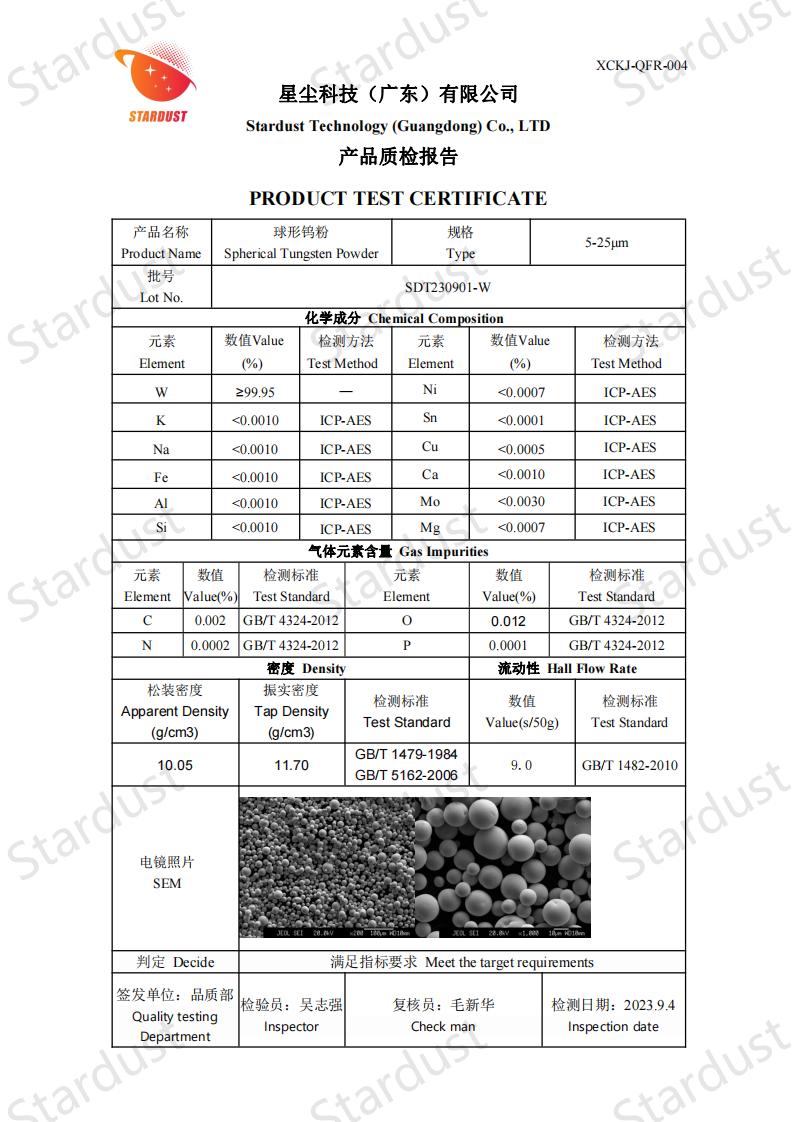

Spherical Tungsten Powder 5-25µm

产品型号:

Product Features

Classification:Metal Powders

Keywords: tantalum powder, tungsten powder

Product details

Powder characteristics

Morphology: High sphericity, most particles are regular spherical, smooth surface, no obvious edges and burrs, this form makes the powder flow well and easier to distribute evenly during processing.

Particle size: The particle size distribution is relatively narrow, and different particle size ranges can be obtained through process control, mostly in the micron level, which can meet diverse application needs.

Purity: Under the high-purity preparation environment of radio frequency plasma, the impurity content is effectively reduced, the tungsten powder has high purity, and impurities such as oxygen, carbon, nitrogen and other metal impurities are less, ensuring the stability of product performance.

Density: It has high bulk density and tap density, and is tightly stacked, which helps to improve the density of the product during the molding process and improve the overall performance of the product.

Activity: The specific surface area is moderate, and the surface atoms have certain activity, which can play a good role when compounded with other materials or participating in reactions.

Application field

Electronic field: Used to manufacture electron tube filaments, cathodes of X-ray tubes, etc., using the high melting point and good conductivity of tungsten.

Aerospace: Manufacturing high-temperature parts of aircraft engines, such as turbine blades, combustion chambers, etc., to improve the high-temperature resistance and strength of parts.

Powder metallurgy: It is a key raw material for preparing tungsten-based alloys, such as tungsten-copper alloys, tungsten-nickel-iron alloys, etc., used to manufacture molds, cutting tools, etc., to improve their hardness and wear resistance.

Additive manufacturing: As a 3D printing material, it can manufacture tungsten products of complex shapes to meet the customized needs of parts in special fields.

Lighting field: It is used to make filament materials in light bulbs such as halogen tungsten lamps to ensure the luminous efficiency and service life of lamps.

Preparation process

RF plasma spheroidization process

Related products

-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Stardust Technology (Guangdong) Co., Ltd.

101, Building 1, Liandong Youzhi Zone, Senshuji Road, Nansha Community, Danzao Town, Nanhai District, Foshan City,Guangdong Pro.,China

QR code