-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

PRODUCTS

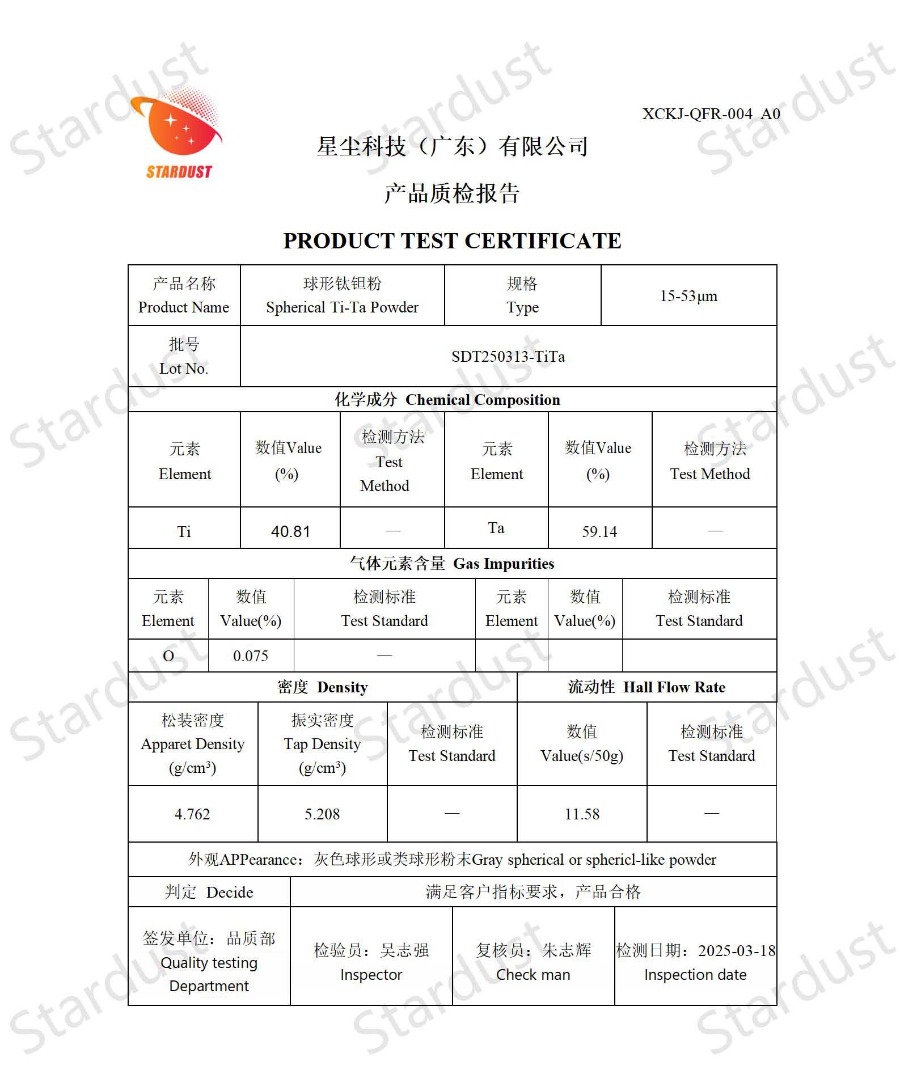

Titanium-tantalum alloy 15-53μm

产品型号:

Product Features

Classification:Metal Powders

Keywords: tantalum powder, tungsten powder

Product details

Titanium-tantalum alloy powder is a new type of functional material with titanium (Ti) as the matrix and tantalum (Ta) as the main alloying element. The typical components are Ti-20TA and Ti-30Ta (by mass fraction), and its properties can be regulated by adding elements such as niobium (Nb), zirconium (Zr), and oxygen (O).

Titanium-tantalum alloy

I.Characteristics

Low density and high specific strength: Density 6.5-10.5 g/cm³ (much lower than pure tantalum 16.6 g/cm³), tensile strength 800-1200 MPa, elongation 15%-25%, combining the light weight and high strength of titanium alloys with the high-temperature resistance of tantalum.

Outstanding corrosion resistance: The addition of tantalum enables the alloy to perform exceptionally well in extreme corrosive environments such as aqua regia, concentrated nitric acid, and high-temperature hydrochloric acid (>150℃), with a corrosion rate of ≤ 0.01mm/year, far exceeding that of pure titanium and Ti-6Al-4V alloys.

Excellent biocompatibility: The naturally formed TiO₂ -TA ₂O₅ composite oxide film on the surface (with a thickness of 5-10 nm) has extremely low cytotoxicity, a hemolysis rate of < 0.1%, and better bone binding ability than pure titanium, meeting the ISO 10993 biosafety standard.

Wide temperature range adaptability: The operating temperature range is from -253 ℃ (in liquid hydrogen environment) to 800℃. There is no brittle transformation at low temperatures, and the high-temperature oxidation resistance is three times that of pure titanium (the oxidation weight gain at 700℃ is ≤5 mg/cm²).

II.Physical Properties

Sphericity and fluidity: The sphericity of the gas atomized powder is ≥95%, the proportion of satellite spheres is < 3%, and the Hall flow rate is ≤12 s/50g. It is suitable for additive manufacturing technologies such as laser selective melting (SLM) and electron beam melting (EBM).

Particle size distribution: Common particle size ranges are 15-53μm (additive manufacturing) and 50-150μm (powder metallurgy). The particle size uniformity index (span factor) is ≤1.5. The bulk density is 3.5-5.0 g/cm³, and the tapped density is 5.5-7.0 g/cm³.

Purity control: Oxygen content ≤1000 ppm (medical grade) /2000 ppm (industrial grade), nitrogen content ≤100 ppm, carbon content ≤50 ppm, total amount of impurity elements (Fe, Ni, W) < 0.1%.

III.Application Fields

1.Additive manufacturing (3D printing) : It is used to manufacture complex-structured metal parts, such as aerospace components, industrial molds and consumer goods.

2.Chemical Engineering and Marine Engineering: It is used for manufacturing corrosion-resistant equipment and catalyst carriers.

3.Electronic Information and Energy: It is used in the manufacture of current collectors for lithium-ion batteries and fuel cells.

Related products

-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Stardust Technology (Guangdong) Co., Ltd.

101, Building 1, Liandong Youzhi Zone, Senshuji Road, Nansha Community, Danzao Town, Nanhai District, Foshan City,Guangdong Pro.,China

QR code