-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

PRODUCTS

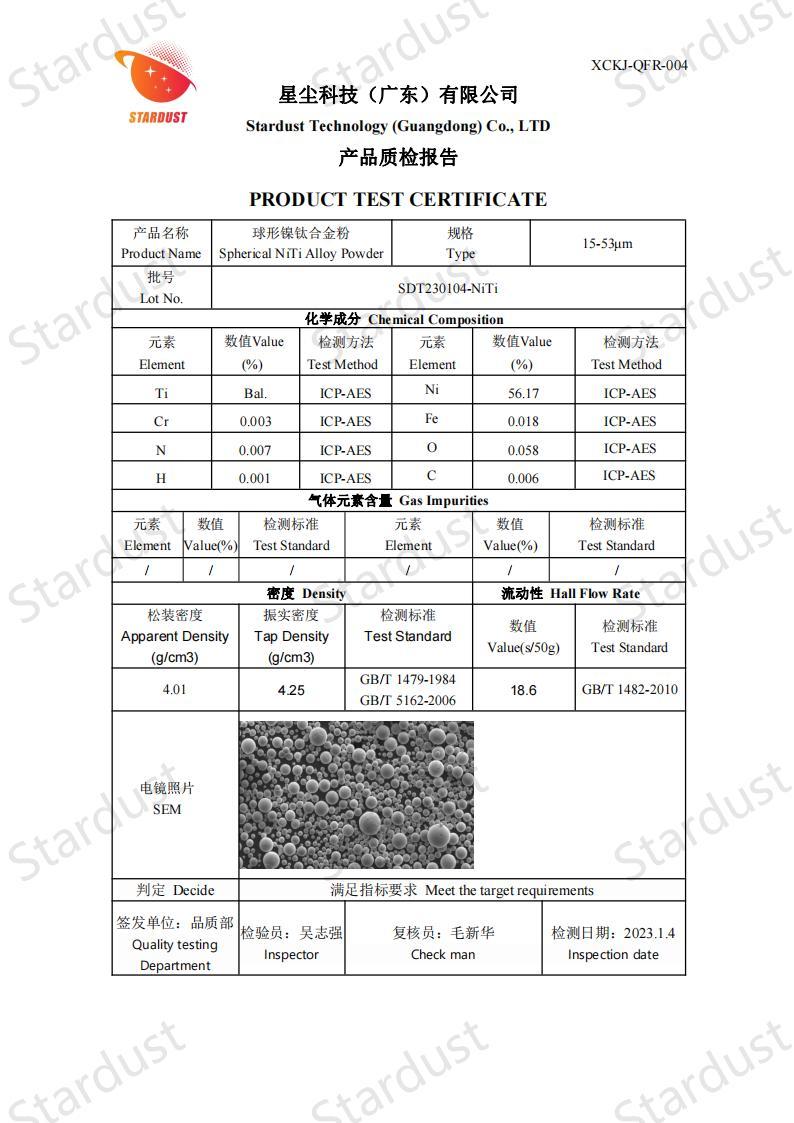

Spherical Ni-Ti Alloy Powder 15-53μm

产品型号:

Product Features

Classification:Metal Powders

Keywords: tantalum powder, tungsten powder

Product details

Spherical Ni-Ti alloy powder is a functional material with unique shape memory effect and superelasticity, which is widely used in the fields of medical, aerospace and smart materials.

1. Characteristics

1 High sphericity: Spherical Ni-Ti alloy powder has regular particle shape and good fluidity, which is suitable for additive manufacturing and powder metallurgy.

2 High density: The density of Ni-Ti alloy is about 6.45 g/cm³, which can provide good mechanical strength.

3 Phase transition temperature: Ni-Ti alloy has a unique martensitic phase transition temperature (Ms, Mf, As, Af), which can be precisely controlled by adjusting the composition.

4 Good thermal conductivity and electrical conductivity: Suitable for thermal management and electronic applications.

5 Excellent corrosion resistance: Ni-Ti alloy forms a dense oxide layer at room temperature and has excellent corrosion resistance, especially in biological environments.

6 Biocompatibility: Ni-Ti alloy is non-toxic and harmless to human tissue and is suitable for medical implants.

7 Chemical stability: It is stable in most chemical environments and is not easy to react with other substances.

8 Shape memory effect: Ni-Ti alloy can restore its original shape when heated above the phase transition temperature.

9 Superelasticity: Below the phase transition temperature, Ni-Ti alloy exhibits superelasticity, which can withstand large deformation and restore its original shape.

10 High fatigue life: Ni-Ti alloy exhibits excellent fatigue performance under cyclic load.

11 Good ductility: Suitable for processing and manufacturing of complex shapes.

2. Application fields

1 Medical field

- Orthopedic implants: used to manufacture orthopedic implants such as spinal orthoses, bone nails and bone plates.

- Cardiovascular stents: used to manufacture cardiovascular stents, taking advantage of its superelasticity and shape memory effect.

- Dental instruments: used to manufacture dental orthoses and implants.

- Minimally invasive surgical tools: used to manufacture minimally invasive surgical instruments such as catheters and guidewires.

2 Aerospace

- Smart structures: used to manufacture smart structures such as deformable wings and satellite antennas.

- Shock absorbers: used to manufacture shock absorbers and dampers, taking advantage of its superelasticity.

- High temperature parts: used to manufacture structural parts in high temperature environments.

3. Smart materials

- Shape memory alloy devices: used to manufacture shape memory alloy devices such as temperature sensors and actuators.

- Robots: used to manufacture robot drives and joints.

4 Industrial fields

- Connectors: used to manufacture high-reliability connectors and fasteners.

- Molds: used to manufacture molds with complex shapes.

III. Preparation method

Gas Atomization

Related products

-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Stardust Technology (Guangdong) Co., Ltd.

101, Building 1, Liandong Youzhi Zone, Senshuji Road, Nansha Community, Danzao Town, Nanhai District, Foshan City,Guangdong Pro.,China

QR code