-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

PRODUCTS

Spherical W-25Re Powder 10-30μm

产品型号:

Product Features

Classification:Metal Powders

Keywords: tantalum powder, tungsten powder

Product details

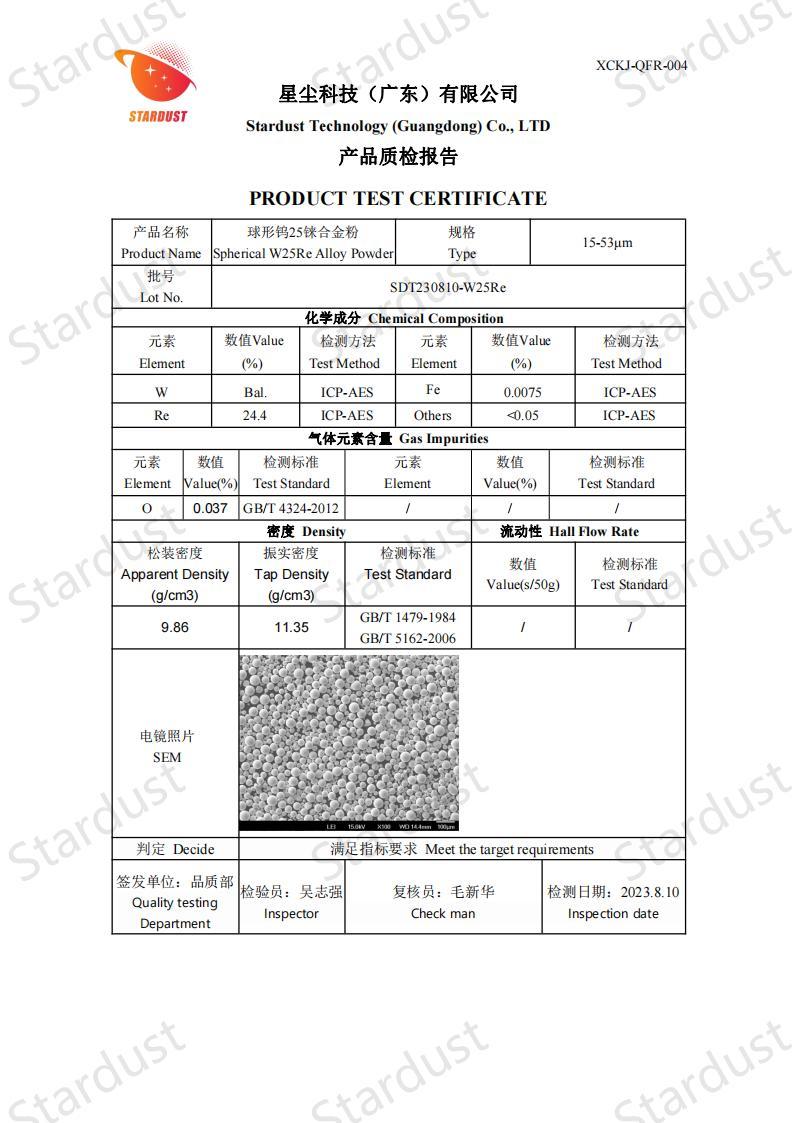

Spherical W-25Re powder is a high-performance refractory metal material with excellent physical, chemical and mechanical properties. It is widely used in industrial fields under high temperature, high stress and extreme environments.

1. Characteristics

1 High melting point: The melting point of tungsten is about 3422°C, and the melting point of rhenium is about 3186°C. The melting point of W-25Re alloy is extremely high, which is suitable for ultra-high temperature application scenarios.

2 High density: The density of W-25Re alloy is about 19.3 g/cm³, which can provide excellent mechanical strength and wear resistance.

3 Good thermal conductivity and electrical conductivity: Suitable for high-temperature thermal management and electronic applications.

4 Low vapor pressure: Low vapor pressure at high temperature, suitable for vacuum and high temperature environments.

5 Excellent corrosion resistance: W-25Re alloy shows excellent corrosion resistance in most acidic and alkaline environments.

6 Oxidation resistance: At high temperatures, a stable oxide layer is formed on the surface of the alloy, providing good oxidation resistance.

7 Chemical stability: It is stable in high temperature and corrosive environment and is not easy to react with other substances.

8 High hardness: W-25Re alloy has extremely high hardness and is suitable for manufacturing wear-resistant parts.

9 Good ductility: Compared with pure tungsten, the addition of rhenium significantly improves the ductility of the alloy and is suitable for processing complex shapes.

10 High strength: It still maintains high strength at high temperature and is suitable for withstanding high stress environment.

11 Creep resistance: It has excellent creep resistance at high temperature and is suitable for long-term high temperature use.

III. Preparation method

RF plasma spheroidization method

Related products

-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Stardust Technology (Guangdong) Co., Ltd.

101, Building 1, Liandong Youzhi Zone, Senshuji Road, Nansha Community, Danzao Town, Nanhai District, Foshan City,Guangdong Pro.,China

QR code