-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

PRODUCTS

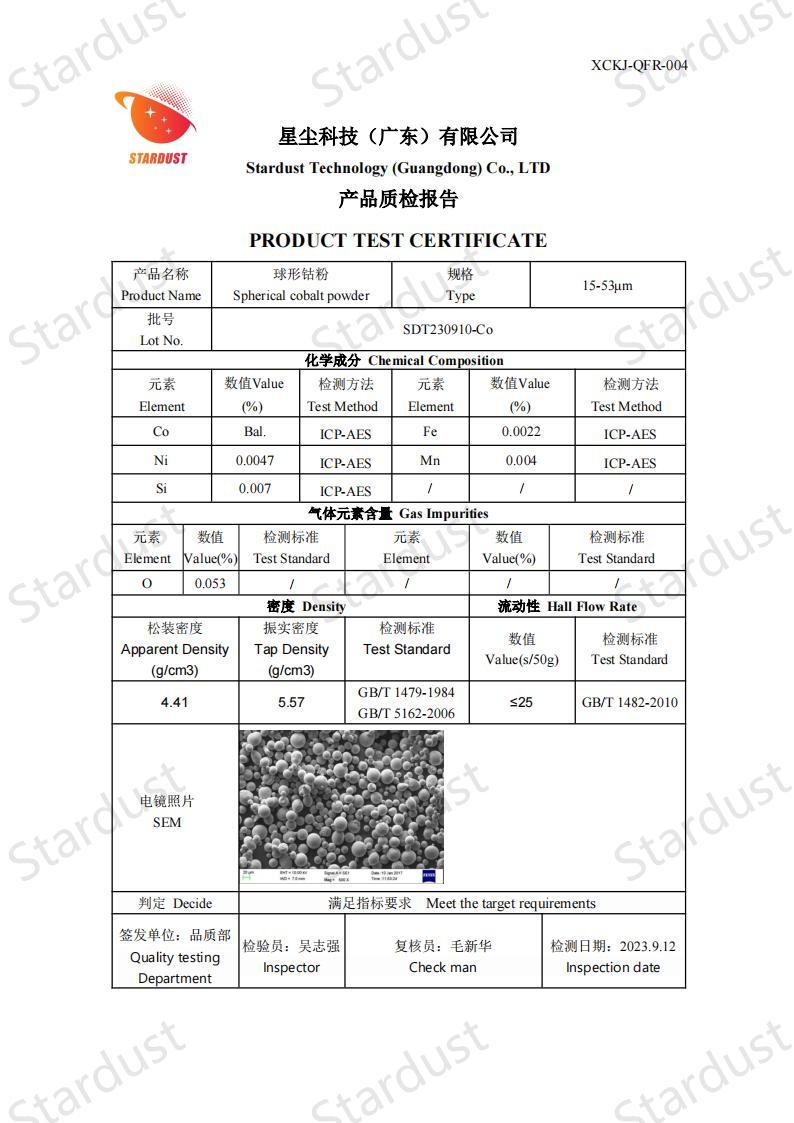

Spherical Co Powder 15-53μm

产品型号:

Product Features

Classification:Metal Powders

Keywords: tantalum powder, tungsten powder

Product details

Spherical cobalt powder is an important metal powder material. Due to its unique physical, chemical and mechanical properties, it has a wide range of applications in many high-tech fields.

1. Characteristics

1 High sphericity: Spherical cobalt powder particles have regular shapes and good fluidity, which are suitable for additive manufacturing and powder metallurgy.

2 High density: The density of cobalt powder is about 8.9g/cm³, and the higher density gives it good mechanical strength and wear resistance.

3 High melting point: The melting point of cobalt is about 1495°C, which is suitable for use in high temperature environments.

4 Good thermal conductivity and electrical conductivity: Cobalt powder has high thermal conductivity and electrical conductivity, and has obvious advantages in electronic and thermal management applications.

5 Excellent corrosion resistance: Cobalt forms a dense oxide layer at room temperature, which makes it have excellent corrosion resistance, especially in acidic and alkaline environments.

6 Antioxidation: At high temperatures, a stable oxide layer is formed on the surface of cobalt powder, which has good antioxidation properties.

7 Chemical stability: Cobalt powder is stable in most chemical environments and is not easy to react with other substances.

8 High hardness: Cobalt powder has high hardness and is suitable for manufacturing wear-resistant parts.

9 Good ductility: At high temperatures, cobalt powder still maintains good ductility, which is convenient for processing complex shapes.

10 High strength: Cobalt powder has high mechanical strength and can withstand high stress environments.

2. Application areas

1 Additive manufacturing (3D printing)

- Metal 3D printing: used for metal 3D printing to manufacture complex-shaped parts such as aerospace parts and medical devices.

- Rapid prototyping: used in rapid prototyping technology to shorten product development cycles.

2 Powder metallurgy

- Wear-resistant parts: used to manufacture high-wear-resistant parts such as bearings, gears and cutting tools.

- Cemented carbide: used as a binder phase in cemented carbide (such as WC-Co), which can improve the hardness and wear resistance of the material.

3. Battery industry

- Lithium-ion battery: used in positive electrode materials (such as LiCoO₂) for lithium-ion batteries, which can provide high energy density and stability.

- Supercapacitor: used as an electrode material for high-performance supercapacitors.

4. Chemical Industry

- Catalyst: In chemical reactions, it can be used as a catalyst or catalyst carrier, such as in Fischer-Tropsch synthesis and hydrogenation reactions.

- Corrosion-resistant equipment: Used to manufacture corrosion-resistant chemical equipment, such as reactors and pipelines.

5. Electronic Industry

- Magnetic Materials: Used to manufacture magnetic materials, such as permanent magnets and magnetic recording media.

- Electronic Components: Used to manufacture high-temperature electronic components, such as resistors and capacitors.

6. Medical Field

- Medical Devices: Used to manufacture high-precision medical devices, such as surgical tools and implants.

- Biocompatible Materials: Cobalt alloys have good biocompatibility and are suitable for orthopedic implants.

III. Preparation Method

Gas Atomization

Related products

-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Stardust Technology (Guangdong) Co., Ltd.

101, Building 1, Liandong Youzhi Zone, Senshuji Road, Nansha Community, Danzao Town, Nanhai District, Foshan City,Guangdong Pro.,China

QR code