-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

PRODUCTS

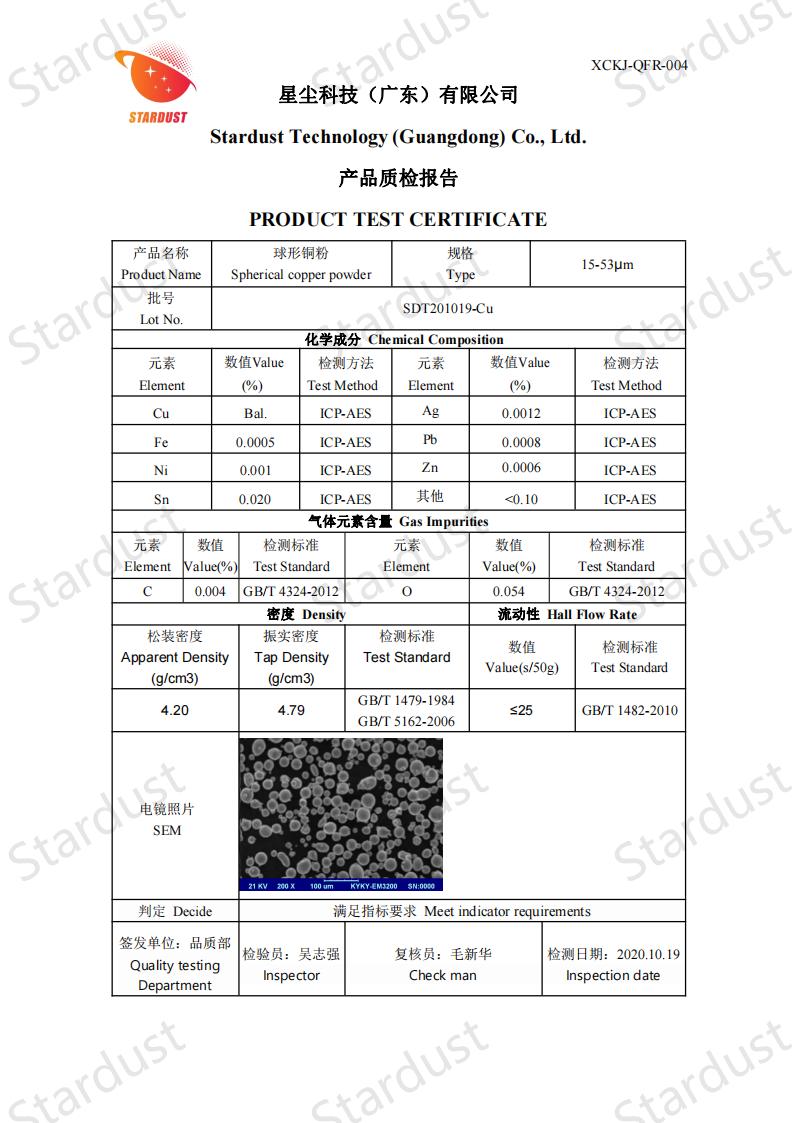

Spherical copper powder 15-53μm

产品型号:

Product Features

Classification:Metal Powders

Keywords: tantalum powder, tungsten powder

Product details

Powder properties

Morphology: Good sphericity, most particles are relatively regular spherical, the surface is relatively smooth, reducing the agglomeration of particles, which is conducive to uniform dispersion in various media.

Particle size: The particle size distribution can be adjusted according to the preparation process, covering a wide range, ranging from submicron to tens of microns, and can achieve a narrow particle size distribution to meet the particle size requirements of different applications.

Purity: Through appropriate preparation methods, high-purity spherical copper powder can be obtained, and the content of impurities (such as iron, zinc, lead, etc.) is low, ensuring its good electrical conductivity, thermal conductivity and other properties.

Density: The loose density and tap density are moderate, and it has a certain degree of compactness when stacked, providing basic conditions for subsequent molding processing.

Activity: It has a certain chemical activity and can participate in the reaction or combination well in specific chemical reactions or when compounded with other materials.

Application field

Electronic field: used to make electronic paste, such as in the manufacture of printed circuit boards (PCBs), as a material for conductive lines; it can also be used to manufacture electrodes for electronic components, taking advantage of its good conductivity.

Powder metallurgy: As a raw material for preparing copper-based alloys and copper-containing parts, various mechanical parts, bearings, gears, etc. are manufactured through mixing, pressing, sintering and other processes with other metal powders to improve their strength and wear resistance.

Thermal spraying: A copper coating is formed on the metal surface through thermal spraying technology to improve the wear resistance, corrosion resistance and conductivity of the substrate, and is used for mechanical repair and surface protection.

3D printing: As a metal 3D printing material, copper products with complex structures can be manufactured to meet the needs of personalization and customization.

Chemical catalyst: Used as a catalyst or catalyst carrier in some chemical reactions to promote chemical reactions.

Related products

-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Stardust Technology (Guangdong) Co., Ltd.

101, Building 1, Liandong Youzhi Zone, Senshuji Road, Nansha Community, Danzao Town, Nanhai District, Foshan City,Guangdong Pro.,China

QR code