Effect of Multi-Layer Molybdenum-Silicon Coating Preparation on Mechanical Properties of Additively Manufactured Ta10W Alloy

Release time:

2025-10-20

Ta10W alloy exhibits outstanding chemical stability, corrosion resistance, wear resistance, creep resistance, and high-temperature mechanical properties, with a service temperature range of 1600–1900°C. It is a high-temperature material with significant application potential in the aerospace field [1]. However, due to its high melting point of 3080°C, conventional manufacturing methods for complex-shaped components suffer from low production efficiency, low yield rates, and difficulties in fabricating certain intricate structures [2-4].

Selective Laser Melting (SLM) technology employs a laser as the energy source, scanning layer by layer across a bed of metal powder along a predefined model path. The scanned metal powder undergoes melting and solidification to achieve metallurgical bonding, ultimately enabling near-net-shape fabrication of complex components [5-6]. This technology features high energy density, superior shape accuracy, and excellent mechanical properties [7-8], enabling the fabrication of complex, high-performance Ta10W alloy components. Currently, Yang et al. [9] have successfully employed SLM for Ta10W alloy additive manufacturing. However, severe oxidation issues arise in Ta10W alloys manufactured via this method under high-temperature environments (1600–1900°C), limiting their application in such conditions.

The preparation of high-temperature protective coatings is an effective method to enhance the oxidation resistance of SLM-fabricated Ta10W alloys [10-11]. Among these, silicide coatings represent the most extensively studied high-temperature oxidation-resistant coatings, primarily functioning through the formation of a dense SiO₂-like glass oxide film with low oxygen permeability and high-temperature self-healing properties [12]. Li Yongquan et al. [13] developed a silicate-based coating on the Ta alloy surface that, after high-temperature oxidation, formed a SiO₂ layer exhibiting excellent self-healing properties and oxygen diffusion inhibition, demonstrating outstanding high-temperature oxidation resistance at 1100°C. However, compared to traditional pressure processing, the non-uniform stress state of additively manufactured alloys can easily lead to issues such as high-temperature protective coating peeling and shortened component service life [9]. Therefore, enhancing coating bond strength is an urgent challenge in preparing high-temperature oxidation-resistant coatings for additively manufactured Ta10W alloys. Xing et al. [14] developed MoSi₂ coatings with excellent bond strength; however, the silicide reaction between Mo and Si elements to form MoSi₂ generates significant internal stresses, predisposing the coating to cracking. Xiao et al. [15] employed a slurry sintering method to fabricate a dual-layer coating structure that mitigates internal stresses from silicidation, yielding crack-free MoSi₂ coatings. Liu et al. [16] developed MoSi₂-Mo coatings on Ta metal substrates capable of withstanding 360 cycles from room temperature to 1700°C, demonstrating outstanding thermal shock resistance and coating adhesion strength. Cai et al. [17] developed a MoSi₂-ZrSi₂-SiO₂ multilayer coating on Ta10W alloy surfaces that retained full integrity after 10 hours of oxidation at 1800°C, demonstrating outstanding oxidation resistance. Thus, applying multilayer MoSi₂ coatings to the surfaces of additively manufactured Ta10W alloys holds promise for addressing their high-temperature oxidation challenges. Additionally, high-temperature protective coatings require high reflectivity to reduce surface temperatures, thereby extending coating service life. TaSi₂, formed by the reaction between Ta and Si, exhibits an exceptionally high emissivity value of 0.9 and superior radiation performance at elevated temperatures [18]. Moreover, the sintering process for coating preparation reaches temperatures as high as 1400°C, which can easily cause coarsening of the alloy matrix microstructure, thereby reducing the mechanical properties of the coated components [19]. Therefore, the mechanical properties of the specimens after coating preparation also require close attention. Currently, there are few reports on the mechanical properties of additively manufactured Ta10W alloy surfaces after coating preparation.

This study employed the slurry sintering method to fabricate a three-layer molybdenum-silicon-based high-temperature oxidation-resistant coating on the surface of SLM-Ta10W alloy. The microstructure of the Ta10W alloy substrate and coating was characterized using Bruker D8 Advance A25X X-ray diffraction (XRD), Zeiss Gemini SEM 300 scanning electron microscopy (SEM), and energy dispersive spectroscopy (EDS). The tensile properties, microhardness, and coating adhesion strength of the Ta10W alloy substrate and coating were evaluated. The influence of the three-layer molybdenum-silicon coating on mechanical properties was elucidated, providing theoretical guidance for fabricating high-performance high-temperature protective coatings for additive-manufactured Ta10W alloys.

1 Experimental Materials and Methods

1.1 Experimental Materials

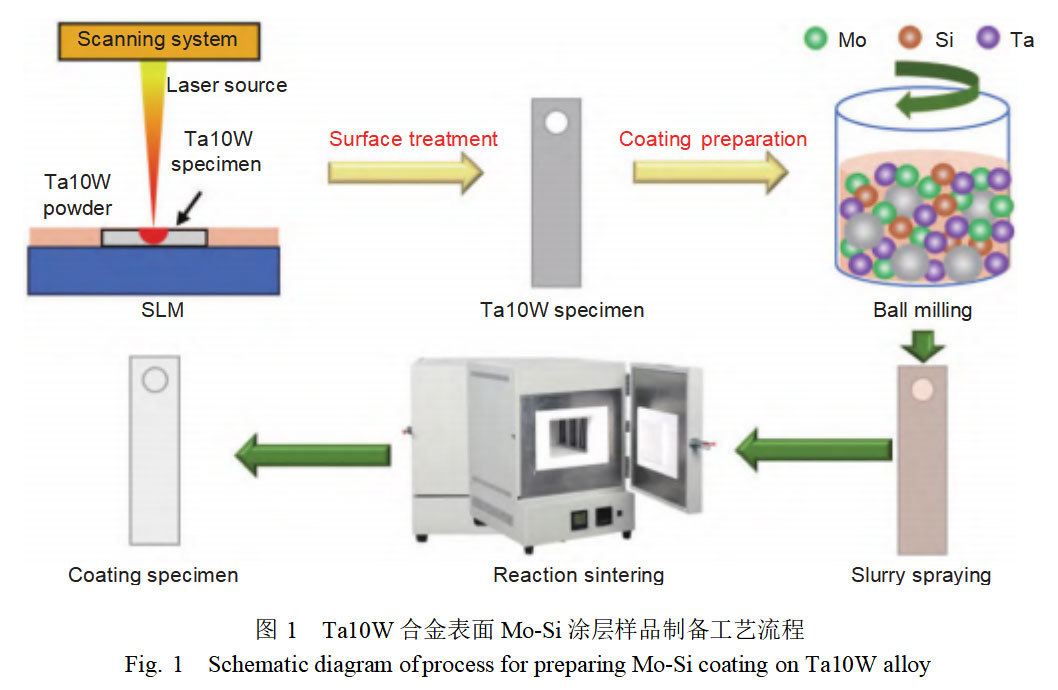

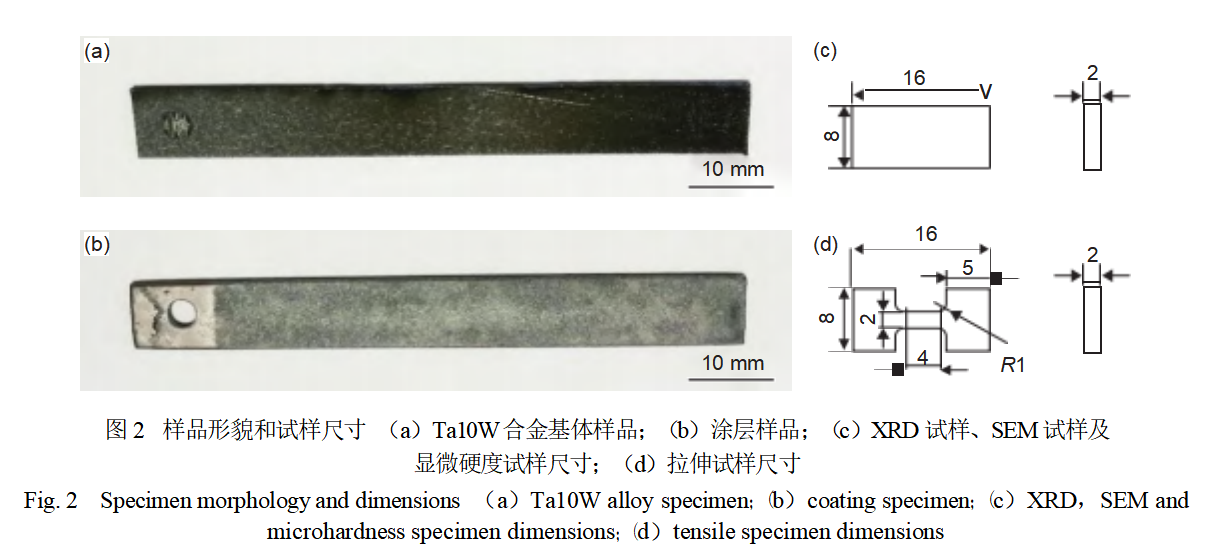

Figure 1 shows the process flow for preparing Ta10W alloy-coated samples. SLM Ta10W alloy substrate samples were provided by Dongfang Tantalum Industry, with an alloy composition of 90Ta-10W (atomic fraction/%, same below). Surface treatment of the SLM Ta10W alloy substrate samples was performed via sandblasting, acid pickling, water rinsing, and drying (Figure 2(a)). Subsequently, coating preparation was conducted on the treated Ta10W alloy substrate surfaces: powders of Si, Ta, and Mo elements were mixed in proportioned ratios and loaded into a ball milling jar with organic solvent. The mixture was ground and blended using a ball mill to produce the coating slurry. The slurry was then uniformly coated onto the Ta10W alloy substrate surfaces and sintered, ultimately yielding the coated samples (Figure 2(b)).

1.2 Experimental Methods

XRD specimens, SEM specimens, microhardness specimens, and tensile specimens were cut using an EDM wire-cutting machine. The dimensions of the XRD, SEM, and microhardness specimens are shown in Figure 2(c), while those of the tensile specimens are shown in Figure 2(d). Phase analysis of the Ta10W alloy and coatings was performed using a Bruker D8 Advance A25 X-ray diffractometer. The microstructure and elemental distribution of the Ta10W alloy matrix and coatings were characterized using a Zeiss Gemini SEM 300 field emission scanning electron microscope and an energy dispersive spectrometer. Room-temperature tensile testing of Ta10W alloy and coating specimens was conducted on an Instron-8801 universal testing machine at a strain rate of 1×10⁻³ s⁻¹. Three parallel specimens were tested for each sample to ensure data accuracy. Microhardness testing of the Ta10W alloy and coatings was performed using a 401MVD microhardness tester. A load of 1.96 N was applied to the outer layer, sub-outer layer, and Ta10W alloy substrate. Due to the inner layer's thickness of only 3.2 μm, a load of 0.098 N was selected for testing, with a holding time of 10 seconds for all layers. Ten test points were taken from each area at 0.5 mm intervals, and the average value was calculated. The coating adhesion strength was tested using an Instron 5882 electronic tensile testing machine, following the testing method and sample dimensions specified in ASTM C633-2013.

2 Results and Analysis

2.1 Microstructure of Ta10W Alloy Matrix and Coating

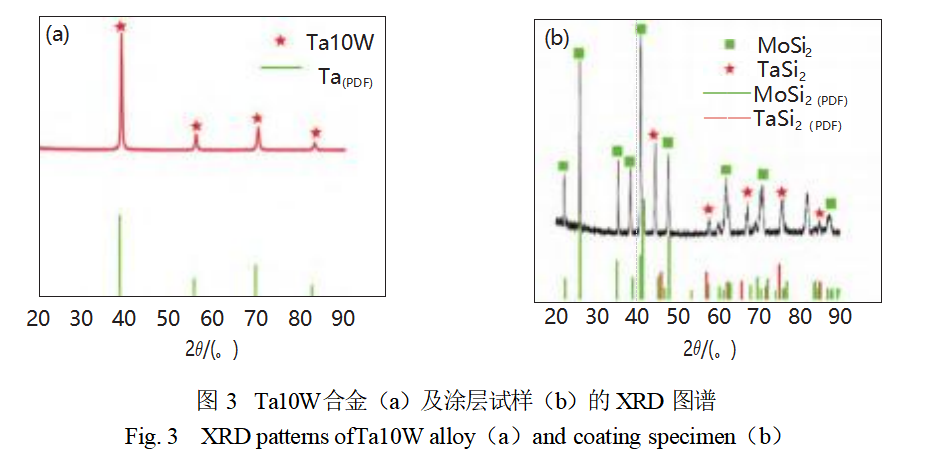

Figure 3 shows the XRD phase analysis results for Ta10W alloy substrate and coating specimens. Characteristic peaks of the alloy substrate shifted to the right compared to the standard diffraction peaks of Ta metal (Figure 3(a)). According to the Bragg equation 2dsinθ = nλ, where d is the interplanar spacing, θ is the incident angle, n is the diffraction order, and λ is the wavelength of X-rays. When the X-ray wavelength remains constant, a decrease in the interplanar spacing causes the incident angle to gradually increase, resulting in a rightward shift of the diffraction peak. Compared to metallic Ta, W atoms partially substitute for Ta atoms in the Ta10W alloy. Since the atomic radius of W is smaller than that of Ta, the interplanar spacing in the Ta10W alloy decreases, leading to the rightward shift of the diffraction peak. As shown in Figure 3(b), characteristic peaks for TaSi₂ and MoSi₂ were detected in the coated sample. The weaker intensity of the TaSi₂ diffraction peak indicates a lower TaSi₂ content on the coating surface.

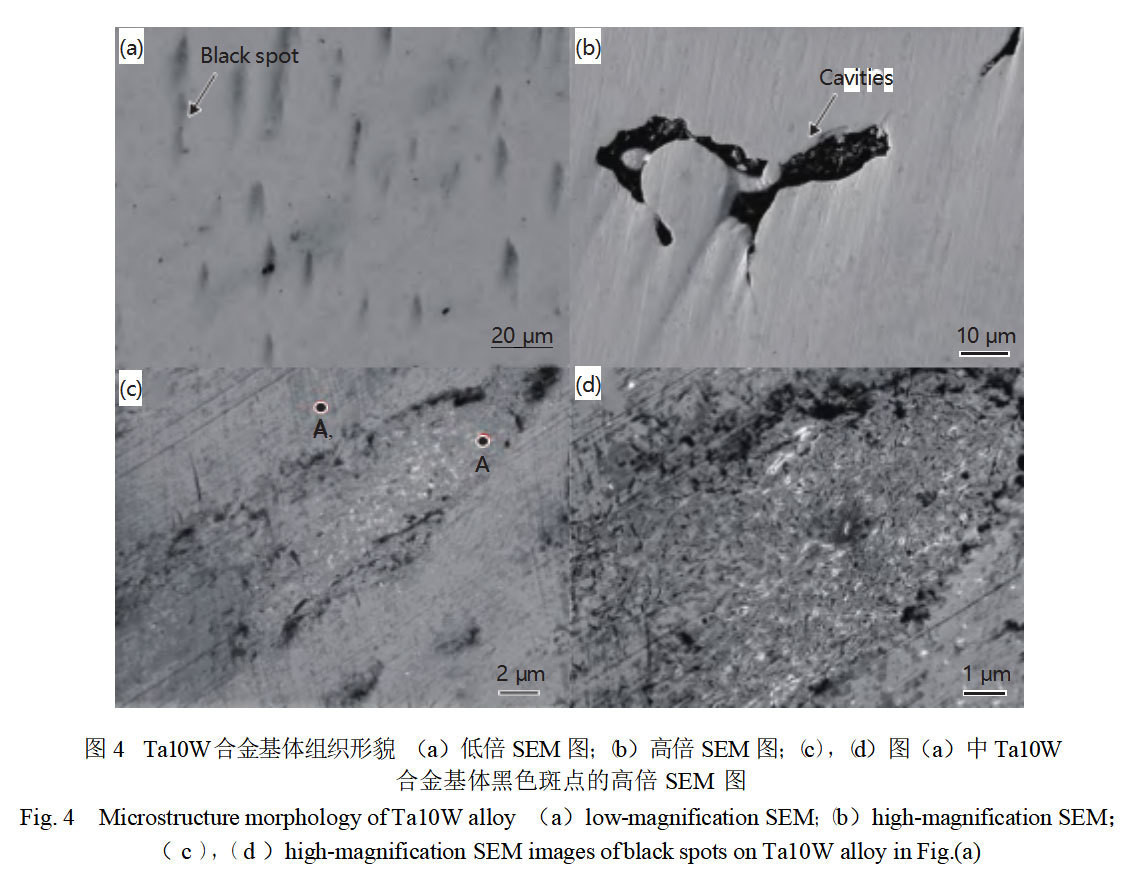

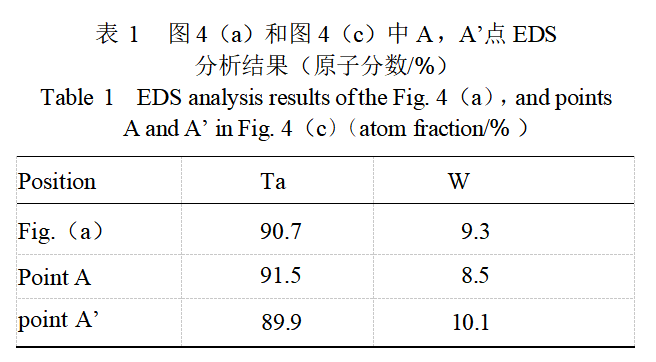

Figure 4(a) displays the SEM morphology of the Ta10W alloy substrate, revealing uniformly distributed black spots and fine pore defects within the alloy matrix. Figure 4(b) shows an enlarged view of the pore defects in the Ta10W alloy matrix, exhibiting irregular strip-like morphology. Figures 4(c) and (d) present enlarged views of the black spots, which consist of a large amount of loose, porous structure. Based on the EDS and XRD results in Table 1 (Figure 3(a)), the alloy matrix is identified as Ta10W. Furthermore, elemental concentrations vary in region (a) of Figure 4, point A within the black spot, and point A' outside the spot. The W content at points A and A' differs by only 1.6%, indicating that the black spots primarily result from a loose, porous microstructure within the Ta10W alloy matrix. In summary, the formation of black spots and fine pore defects stems from the SLM additive manufacturing process, which involves laser melting of powder followed by solidification. This process generates numerous small, regularly distributed micro-melt pools. When significant temperature gradients occur during solidification, uniformly distributed segregation, pores, and other solidification defects form. Numerous literature reports have documented similar phenomena [20-22].

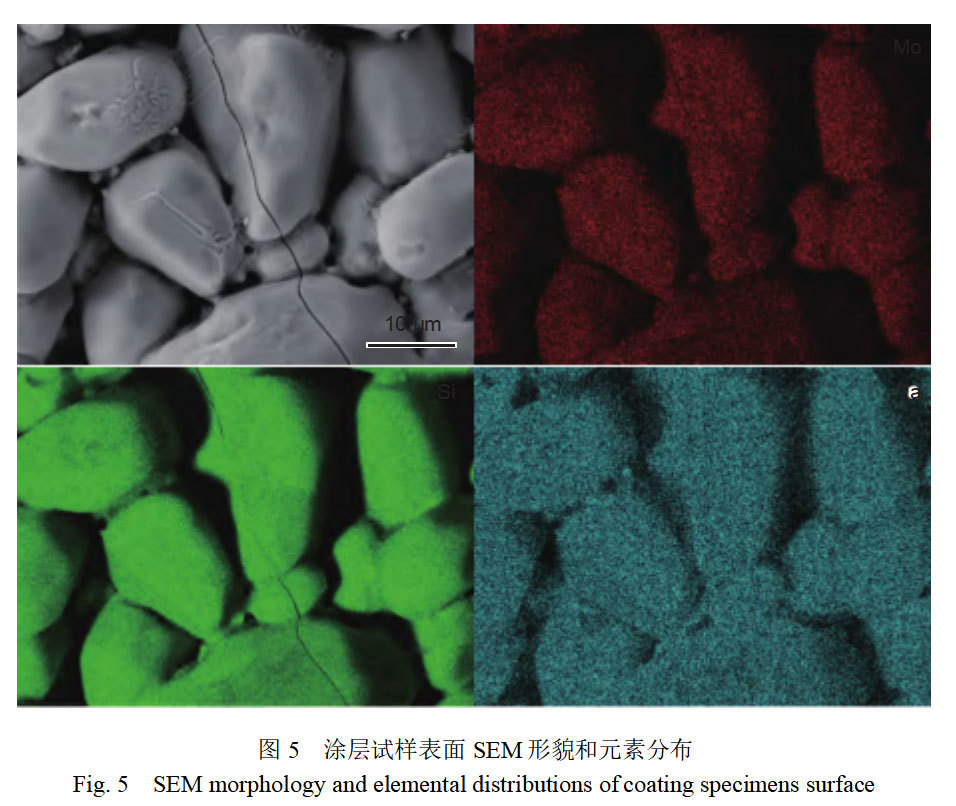

Figure 5 shows the SEM morphology and elemental distribution map of the coated specimen surface. Numerous elliptical particles are observed on the coating surface, with voids between particles and fine cracks on the particle surfaces. As indicated in Figure 5, the primary elements in the surface particles are Si, Ta, and Mo, distributed uniformly. The higher brightness of Si elements indicates a higher Si content on the coating surface.

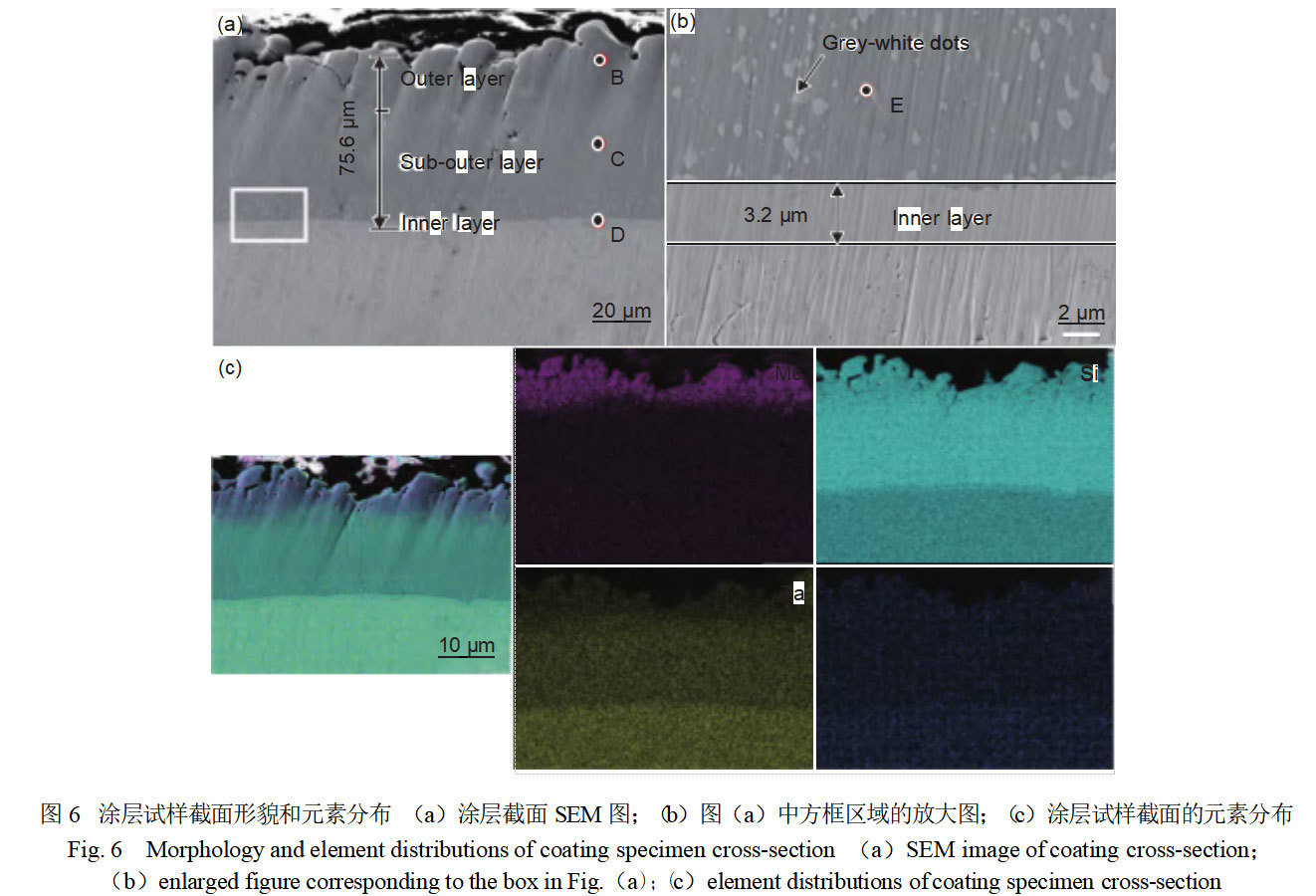

Figure 6(a) presents the SEM image of the coating cross-section, with a total thickness of 75.6 μm. Based on SEM contrast variations, the coating exhibits a three-layer structure comprising an outer layer, a sub-outer layer, and an inner layer. The outer layer appears dark gray with porosity defects, primarily containing Mo, Si, and trace Ta (Figure 6(c)). The sub-outer layer appears gray with a dense, uniform structure, predominantly composed of Ta and Si elements (Figure 6(c)). Additionally, numerous gray-white dots are distributed throughout the sub-outer layer, with dot diameters increasing toward the inner layer (Figure 6(b)). The inner layer exhibits a gray-white color and dense structure, with a thickness of 3.2 μm (Figure 6(b)). Furthermore, the interfaces between layers are sharp and straight, indicating excellent coating uniformity. Elemental diffusion is evident across the three-layer structure, with chemical element distribution exhibiting gradient changes (Figure 6(c)).

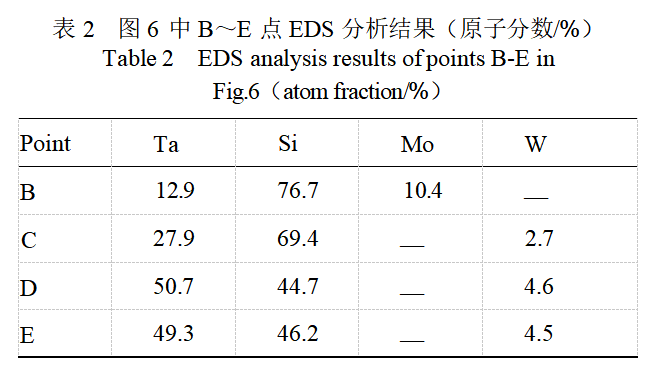

Table 2 lists the chemical compositions at various points in Figures 6(a) and (b). The outer layer primarily consists of TaSi₂ and MoSi₂ phases, the sub-outer layer mainly comprises TaSi₂ phase, the gray dots in the sub-outer layer correspond to Ta₅Si₃ phase, and the inner layer predominantly contains Ta₅Si₃ phase. The sub-outer and inner layers contain trace amounts of W, resulting from diffusion of W from the Ta10W alloy substrate during coating preparation.

2.2 Mechanical Properties of Ta10W Alloy Substrate and Coatings

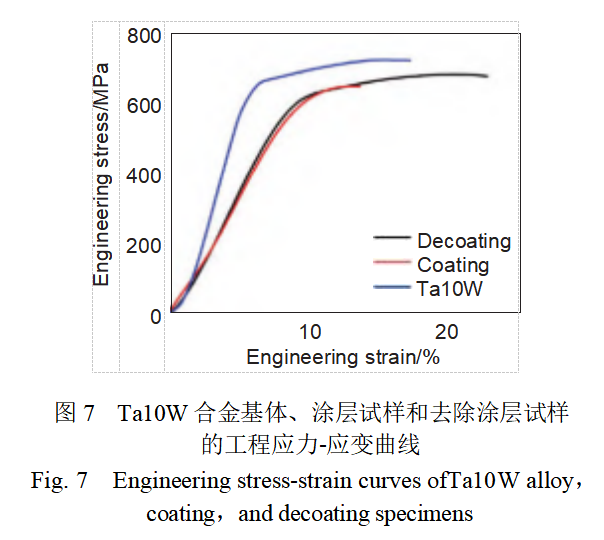

Figure 7 shows the engineering stress-strain curves for Ta10W alloy substrate, coated specimens, and specimens with removed coatings. The yield strength, tensile strength, and uniform elongation of the Ta10W alloy substrate, coated specimen, and de-coated specimen were 660, 720 MPa, and 17.2%; 639, 647 MPa, and 13.6%; and 602, 675 MPa, and 22.7%, respectively. Compared to the Ta10W alloy substrate specimens, the uniform elongation of the coating-removed specimens increased by 5.5%, but the yield strength and tensile strength decreased by 58 MPa and 73 MPa, respectively. Compared to the coating-removed specimens, the elongation of the coated specimens decreased by 9.1%, while the yield strength increased by 37 MPa.

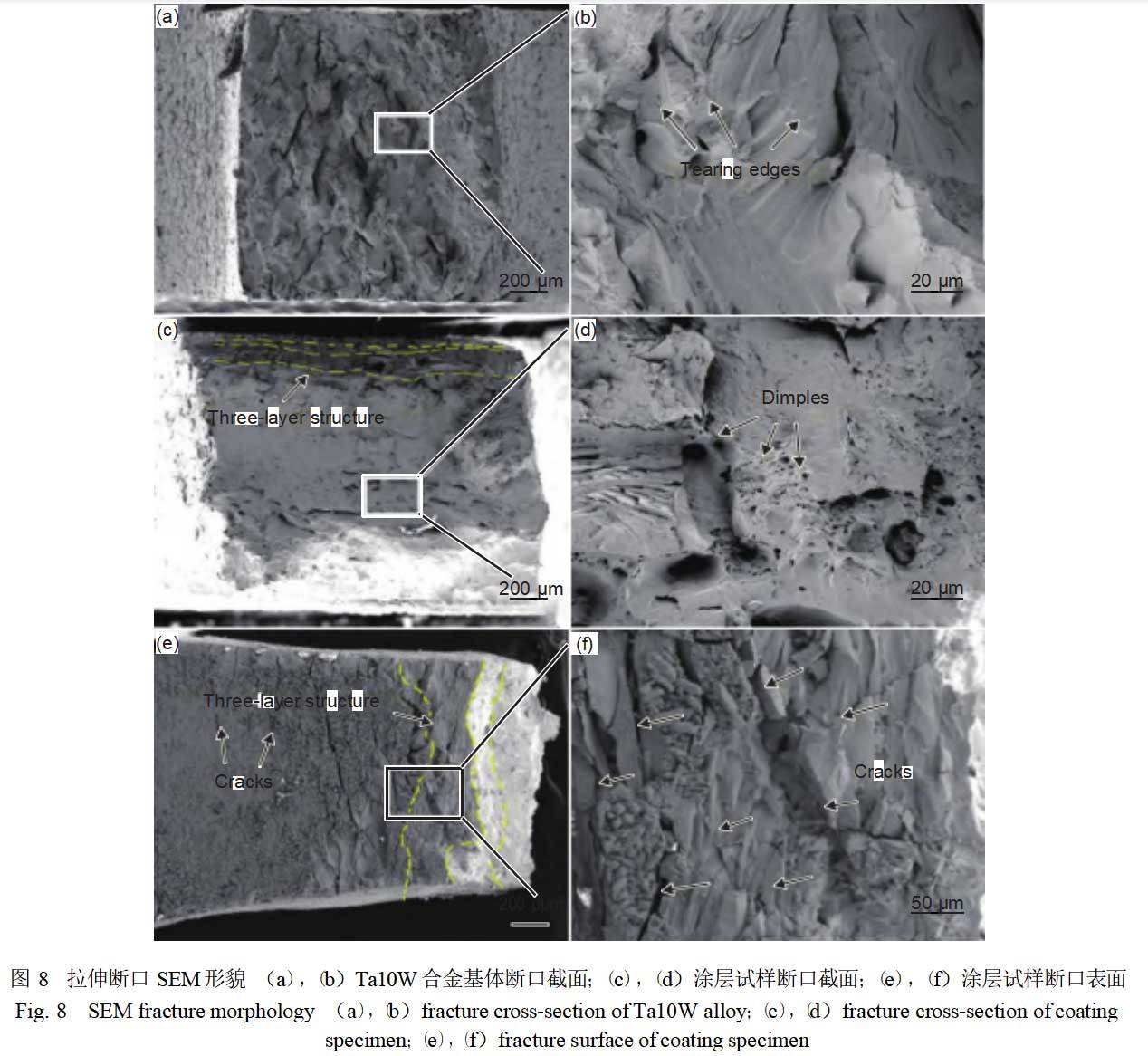

Figure 8 shows the fracture morphology of the Ta10W alloy substrate and coated specimens. As seen in Figure 8(a) and (b), the edges of the Ta10W alloy substrate fracture are flush, with a distinct tearing ridge at the fracture center, exhibiting typical brittle fracture characteristics. This is attributed to the significant temperature gradient and undercooling in the melt pool during SLM, which generates substantial residual stresses during rapid solidification, thereby degrading tensile properties [19]. Figures 8(c) and (d) present the macroscopic fracture morphology of the coated specimen, showing distinct delamination along the fracture edges and pronounced ductile pits at the fracture center, indicating mixed ductile-brittle fracture. The fracture mechanism stems from the sintering process eliminating residual stresses in the SLM Ta10W alloy substrate, thereby enhancing the plasticity of the coated specimens. Figure 8(e) and (f) display the surface morphology of the tensile fracture surfaces, revealing distinct layering on the fracture surfaces with cracks concentrated at the fracture locations. As distance from the fracture site increases, surface cracks in the coating become progressively finer and less numerous, indicating that the coating absorbed tensile stress and enhanced the yield strength of the coated specimen. In summary, the coating preparation process improves the plasticity of the Ta10W alloy substrate. However, the decrease in uniform elongation after coating preparation is attributed to the porous structure of the surface coating, which promotes crack initiation and results in rapid necking.

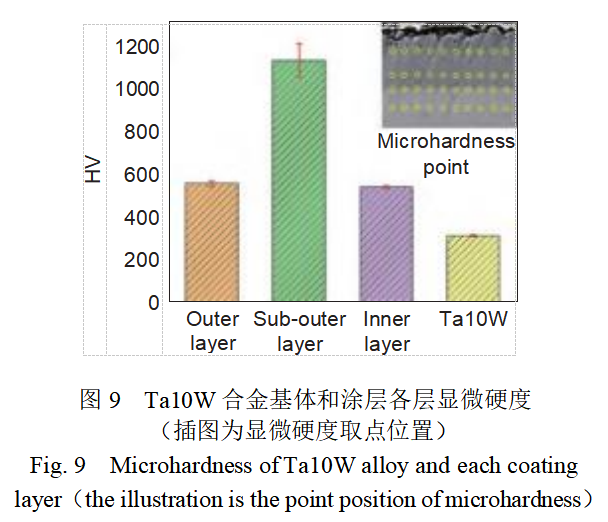

Figure 9 shows the microhardness of the Ta10W alloy substrate and each coating layer. The microhardness values for the coating outer layer, sub-outer layer, inner layer, and Ta10W alloy substrate are 550HV0.2, 1120HV0.2, 534HV0.01, and 307HV0.2, respectively. The primary reason for the differing hardness across coating layers is their distinct phase compositions. The TaSi₂ phase exhibits higher hardness than both MoSi₂ and Ta₅Si₃ phases, and the presence of harder phases increases microhardness [11]. The outer coating layer features a loose microstructure containing MoSi₂ phase (Figure 6), resulting in lower microhardness than the sub-outer layer. The sub-outer layer exhibits a dense microstructure with abundant TaSi₂ phase (Figure 6), resulting in higher microhardness. The inner layer consists of Ta₅Si₃ phase (Figure 6), leading to lower microhardness than the sub-outer layer. The microhardness of the additive-manufactured Ta10W alloy matrix is comparable to that of conventionally cast Ta10W alloy [1].

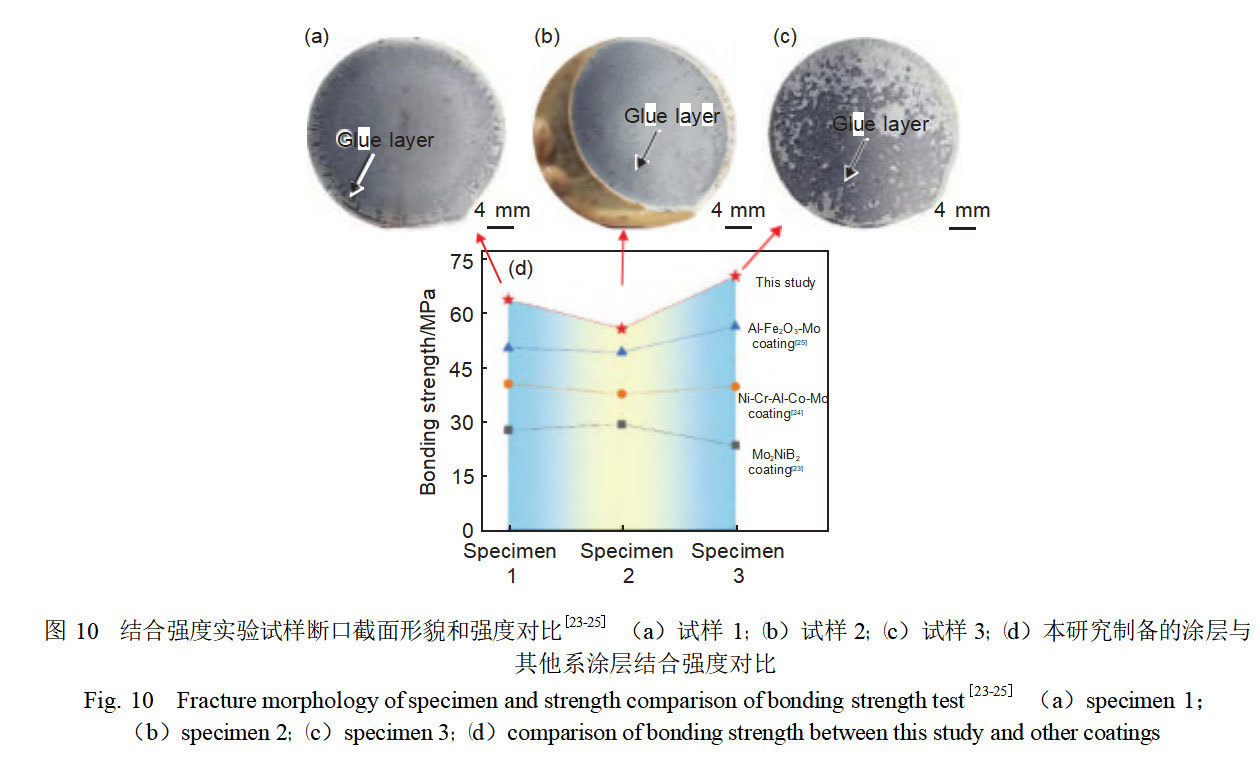

Figure 10(a) to (c) show the fracture surface morphology of parallel coating specimens 1, 2, and 3, respectively. A gray adhesive layer is distributed across the surfaces of all three parallel specimens, indicating that the fracture mode was adhesive failure in all cases. Figure 10(d) shows the bond strengths of the three parallel coated specimens to be 64, 56, and 70 MPa, respectively, with an average bond strength of 63 MPa. Compared to currently superior ceramic-based coatings and high-entropy alloy coatings [23-25], the three-layer molybdenum-silicon-based coating prepared in this study exhibits outstanding bond strength. The significant improvement in bond strength stems from the gradient composition of the coating forming a multilayer structure (Figure 6). This structure includes a 3–5 μm diffusion layer (inner layer) between the coating and substrate, indicating that the slurry sintering method achieves good metallurgical bonding between the coating and substrate. Additionally, the dense microstructure of the coating plays a crucial role in enhancing its bond strength.

3 Conclusions

(1) The coating formed by laser selective melting on the Ta10W alloy surface exhibits a three-layer structure comprising an outer layer, a sub-outer layer, and an inner layer. The outer layer consists of TaSi₂ and MoSi₂ phases, the sub-outer layer comprises TaSi₂ phases and Ta₅Si₃ phases dispersed near the inner layer, while the inner layer is composed of Ta₅Si₃ phases. The interfaces between coating layers are straight, indicating good bonding. Elemental diffusion is evident between the three layers, resulting in a gradient change in chemical composition.

(2) The yield strength, tensile strength, and uniform elongation of the coated specimens and the specimens with the coating removed were 639 MPa, 647 MPa, and 13.6%, and 602 MPa, 675 MPa, and 22.7%, respectively. Compared to the Ta10W alloy substrate specimens, the uniform elongation of the de-coated specimens increased by 5.5%. This increase resulted from the thermal effects during coating preparation eliminating residual stresses in the laser selective melting-formed Ta10W alloy. The coating specimen exhibited a 37 MPa increase in yield strength but a 9.1% decrease in elongation. This was attributed to the coating preparation enhancing yield strength, while the porous structure of the surface coating promoted crack initiation and accelerated necking.

(3) The microhardness values for the outer layer, sub-outer layer, inner layer, and Ta10W alloy were 550HV0.2, 1120HV0.2, 534HV0.01, and 307HV0.2, respectively. The significant increase in hardness of the sub-outer layer resulted from the higher hardness of the TaSi2 phase. The average bond strength between the three-layer coating and the alloy substrate was 63 MPa. This significant improvement in bond strength resulted from the dense microstructure of the molybdenum-silicon high-temperature oxidation-resistant coating and its strong metallurgical bonding with the substrate.

Reference: LIN Jia,WANG Wen,WANG Lifei,et al. Effect of multi-layer structure molybdenum-silicon coating preparation on mechanical properties of additive manufacturing Ta10W alloy[J]. Journal of Aeronautical Materials,2024,44(6):44-52.

Stardust Technology's spherical Ta10W alloy powder is produced using radiofrequency plasma spheroidization technology. The powder particle size ranges from 1 to 150 μm, featuring high purity, low oxygen content, high sphericity, smooth surfaces free of satellite particles, and uniform particle size distribution. It also exhibits excellent flow properties with high bulk and tapped densities. This powder inherits the Ta10W alloy's high melting point, high density, excellent thermal conductivity, superior corrosion resistance, and high-temperature strength. It maintains good ductility at elevated temperatures, making it suitable for applications such as 3D printing to manufacture aerospace high-temperature components, nuclear reactor assemblies, and corrosion-resistant chemical equipment.Welcome to contact our manager Cathie Zheng +86 13318326187.

News