Effect of Process Parameters on Single-Beam Melting Characteristics of W-25%Re Alloy via Selective Laser Melting

Release time:

2025-09-28

Tungsten-rhenium alloys exhibit high melting points, superior high-temperature strength, and excellent radiation resistance, finding extensive applications in electronics, aerospace, and defense industries [1-2]. With the rapid advancement of selective laser melting (SLM) technology in industrial applications, fabricating complex-structured tungsten-rhenium alloy components via SLM has become a research hotspot [3-8]. SLM is a material forming process that builds structures layer by layer from points, lines, and surfaces to volumes, characterized by complex rapid heating and solidification during formation [9-11]. The single melt channel serves as the fundamental unit in SLM-fabricated parts. Its characteristics directly influence the powder spreading process and forming quality of the subsequent layer, significantly impacting the final part's performance [12]. Consequently, researchers typically initiate studies on single melt channel forming during SLM part fabrication to explore the initial forming process parameter window before proceeding to full part production. Furthermore, the dimensional accuracy of complex SLM-fabricated parts—such as those with internal flow channels, thin walls, curved surfaces, or porous structures—largely depends on the quality of single melt channel formation [13]. Consequently, investigating single melt channel formation serves as an effective approach to derive process parameter windows for SLM part fabrication, holding significant importance for producing high-quality components.

Research on single-beam forming typically focuses on surface morphology, geometric dimensions (e.g., melt width, depth, height, and contact angle), spheroidization phenomena, and cracking. Process parameters such as laser power and scanning speed significantly influence the forming quality of single beams. Regarding surface morphology and geometric dimensions of single melt tracks, Wu et al. [14] investigated SLM single-track scanning of pure tungsten. They found melt track width increased with laser power, decreased with scanning speed, and exhibited a morphological transition from irregular to straight to irregular. Height differences between melt tracks initially decreased then increased. Ren et al. [15] also investigated this phenomenon, obtaining single melt channels exhibiting smooth and regular, irregular, and spheroidized characteristics under varying laser power and scan speed conditions. At lower laser powers, increasing scan speed resulted in irregular single melt channel morphology with significant width variation. At higher scanning speeds, spheroidization occurs on the single melt channel surface; conversely, at lower scanning speeds, excessive input energy density destabilizes the melt pool, inducing Marangoni effects that also cause irregularities. Guo et al. [16] observed that single melt channels exhibit regular and smooth surface morphologies under high laser power conditions, while higher scanning speeds tend to induce shrinkage and irregularities. Additionally, as laser power increases, the contact angle between pure tungsten droplets and the substrate gradually decreases, while penetration depth progressively increases. Conversely, as scanning speed increases, the contact angle gradually increases, and penetration depth progressively decreases. Regarding research on single-track spheroidization, Zhou Xin et al. [17] investigated the laser selective melting/solidification behavior of pure tungsten single-layer powder spreading, elucidating the spheroidization mechanism of pure tungsten droplets. Due to the high viscosity and surface tension of pure tungsten droplets, coupled with tungsten's high thermal conductivity and melting point, these factors collectively cause rapid solidification and spheroidization before the droplets can complete spreading. The authors proposed that enhancing the substrate/powder absorption of the laser and adjusting the laser exposure time (for pulsed lasers) can mitigate this spheroidization tendency. Regarding single-melt-channel crack defects, Chen et al. [18] investigated pure tungsten single-melt-channel structures formed via SLM. At high input line energy densities, cracks appeared along the scanning direction on the single-melt-channel surface; at lower input line energy densities, no significant cracks were observed on the single-melt-channel surface. Wang et al. [19] obtained similar results, observing cracks along the scanning direction on the single melt channel surface, with crack depths reaching up to 200 μm in the melt pool cross-section. Guo et al. [20] proposed that during SLM forming, higher input linear energy densities (exceeding 1.75 J/mm²) induce significant residual stresses due to elevated temperature gradients and cooling rates, leading to surface cracking in single melt channels.

This study investigates the influence of process parameters—including laser power, scanning speed, and substrate material—on the forming quality of W-25Re alloy single melt channels via SLM. Surface morphology and geometric dimensions of the single melt channels are analyzed to explore the process parameter window for SLM forming of W-25Re alloy single melt channels, providing reference for subsequent production of high-quality W-25Re alloy components.

1 Experimental Materials and Forming Scheme

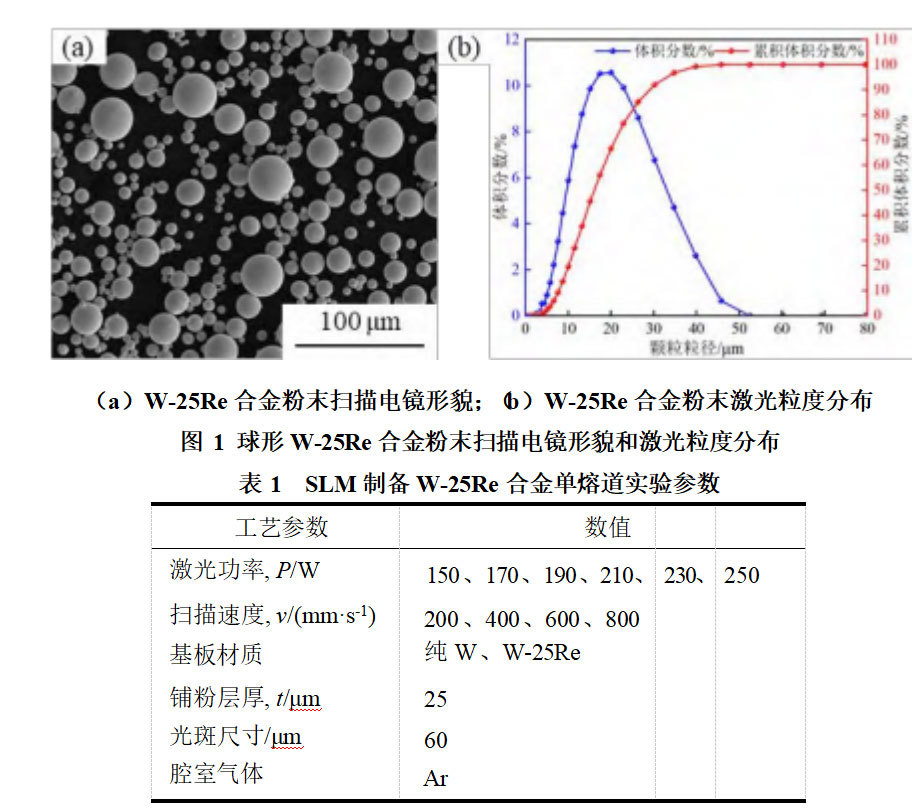

The experimental raw material powder consists of spherical W-25Re alloy powder prepared by the wire-explosion method, with its morphology and laser particle size distribution shown in Figure 1. As depicted in Figure 1, the W-25Re alloy powder comprises uniformly spherical particles with smooth surfaces and high sphericity (see Figure 1(a)); with laser particle size measurements of D10 = 8.938 μm, D50 = 18.419 μm, and D90 = 33.123 μm. The powder size distribution follows a normal distribution with relatively concentrated particle sizes (see Figure 1(b)). The flowability of W-25Re alloy powder is 6.95 s/(50 g), with a bulk density of 12.00 g/cm³ and a tapped density of 13.2 g/cm³. The oxygen content (mass fraction) is 0.0114%.

Single-channel experiments were conducted on W-25Re alloy powder using a DLM-280 metal 3D printing device. The experiments employed a controlled variable method, varying laser power, scanning speed, and substrate material while keeping other parameters constant. Specific parameter settings are detailed in Table 1. The spot diameter was 60 μm, the powder deposition layer thickness was 25 μm, and the chamber gas was high-purity argon. To minimize the impact of random factors on the results, five single-channel scan trajectories were printed for each set of experimental parameters.

Following single-track experiments, specimens underwent 15-minute ultrasonic cleaning in anhydrous ethanol. Surface morphology was then examined using a FEI Nova NanoSEM 450 field emission scanning electron microscope. To further evaluate formation quality, width measurements were taken for single tracks formed under different conditions. The average width was calculated as the mean, with standard deviation determined. The coefficient of variation (ratio of standard deviation to average width) was used as a parameter to evaluate the surface morphology quality of the single melt channel. A coefficient of variation within 15% was considered to indicate good morphology [20].

2 Analysis and Discussion

2.1 Influence of SLM Process Parameters on Single Melt Channel Surface Morphology

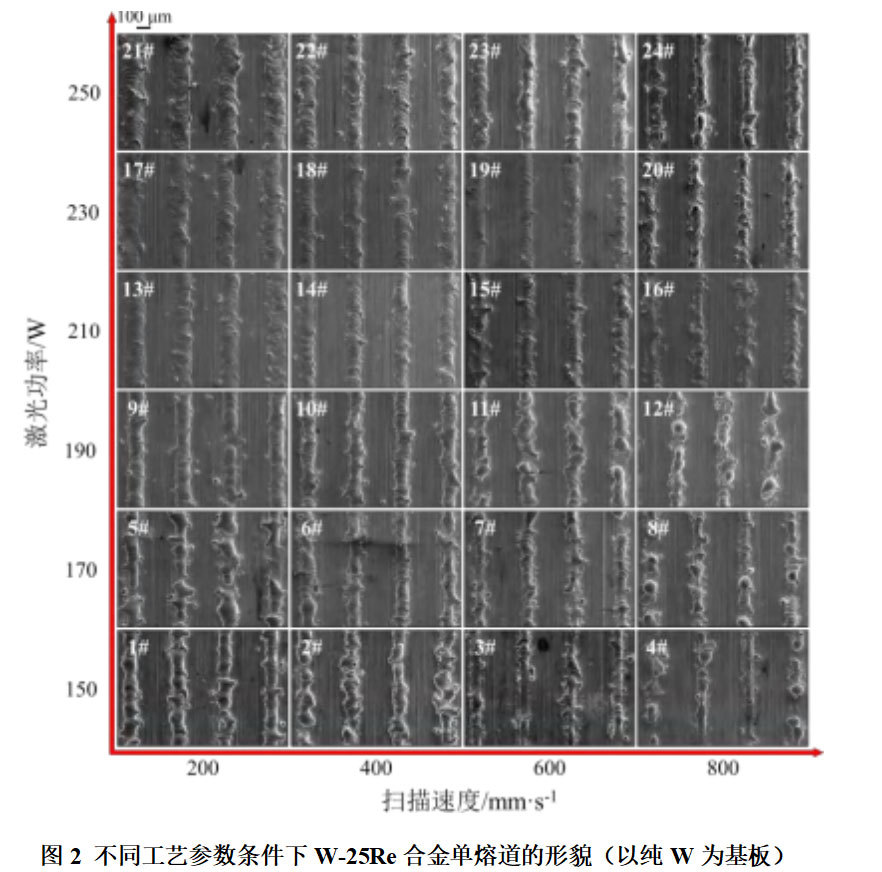

During SLM single-beam forming, W-25Re alloy powder melts under laser irradiation, forming a continuous molten pool through flow, wetting, and spreading processes. Figure 2 shows the surface morphology of W-25Re alloy single-beam tracks formed on pure tungsten substrates under different laser power and scanning speed conditions. As shown in Figure 2, at laser powers of 150W and 170W, spheroidization occurs in the single melt channel, and the channel becomes discontinuous. As the scanning speed increases, the spheroidization and discontinuity of the single melt channel become significantly more pronounced. When the scanning speed is further increased (800 mm/s), the single melt channel can hardly be formed. This occurs because at lower laser input power and higher scanning speeds, the laser interacts with the powder for a shorter duration, resulting in a lower temperature of the molten pool formed after melting the W-25Re alloy powder [14]. At this lower temperature, solidification occurs rapidly. The fluctuations generated by the laser-powder interaction cannot be fully damped within the molten pool, leading to undulating and curved morphologies in the solidified single melt channel. The lower melt pool temperature impairs the liquid metal's flowability, wettability, and spreading ability. With increased surface tension, the liquid metal exhibits a tendency to spontaneously solidify into spheres, causing pronounced spheroidization on the melt channel surface [21]. Additionally, higher laser scanning speeds can cause splatter of liquid metal within the melt pool, which solidifies into spherical droplets and falls onto the single melt channel surface, further contributing to spheroidization. Higher laser scanning speeds also increase the flow velocity of the liquid within the melt pool, causing more pronounced fluctuations in the melt pool. This is another reason for spheroidization and discontinuity in single melt channels. When the laser power is 190W, the single melt channel at a scanning speed of 200mm/s is relatively continuous, and the spheroidization phenomenon is improved. At a scanning speed of 400mm/s, the single melt channel exhibits significant fluctuations, with pronounced rippling on the surface of the single melt channel. Further increasing the scanning speed reintroduces pronounced spheroidization and discontinuity on the single melt track surface. At a laser power of 210W, melt tracks scanned at 200mm/s and 400mm/s exhibit greater continuity, straightness, and relatively smooth surfaces; tracks scanned at 600mm/s and 800mm/s are smaller in size and show some degree of distortion. At a laser power of 230W, melt tracks formed at scanning speeds of 200–600 mm/s exhibited relatively continuous, straight paths with smooth surfaces, while tracks at 800 mm/s showed surface irregularities. At 250W laser power, the 200 mm/s scan speed produced wider melt tracks with noticeable distortion and undulations. Under higher laser power and lower scanning speed conditions, W-25Re alloy powder receives longer laser exposure time. resulting in a higher temperature in the molten pool formed after powder melting. Additionally, more heat diffuses from the molten pool to its surroundings, increasing the temperature gradient between the pool center and edges. This heightened temperature gradient amplifies surface tension differences, triggering intense Marangoni convection. Consequently, the molten pool exhibits significant widthwise fluctuations, leading to pronounced distortion and undulations in the solidified single melt channel [22]. As the scanning speed increases to 400 mm/s, the distortion of the melt channel morphology is mitigated. With increasing laser scanning speed, the laser energy density incident on the W-25Re alloy powder gradually decreases, The temperature of the molten pool formed by the melted W-25Re alloy powder gradually decreased. The temperature gradient between the center and edges of the molten pool diminished, reducing the surface tension difference between them. Consequently, the Marangoni convection induced by the surface tension difference weakened, resulting in less pronounced molten pool fluctuations. Ultimately, the single melt channel formed after solidification exhibited improved surface flatness and a relatively straight profile. When the scanning speed is further increased to 600 mm/s, the input laser energy density decreases further, and the single melt channel exhibits noticeable undulations and slight curvature.

At a laser power of 250 W and a scanning speed of 200 mm/s, the maximum width of the W-25Re alloy single melt channel reaches 147.3 μm. However, at higher scanning speeds, the single melt channel exhibits poor formability with pronounced discontinuities and spheroidization. Overall, increasing laser power significantly improves the formability of the W-25Re alloy single melt channel on a pure tungsten substrate, markedly reducing discontinuities and spheroidization while simultaneously increasing the channel width. Under high laser power and low scanning speed conditions, groups 13, 14, 17, 18, 19, and 22 in Figure 2 exhibit smooth, regular single melt channel morphology without noticeable spheroidization or discontinuity.

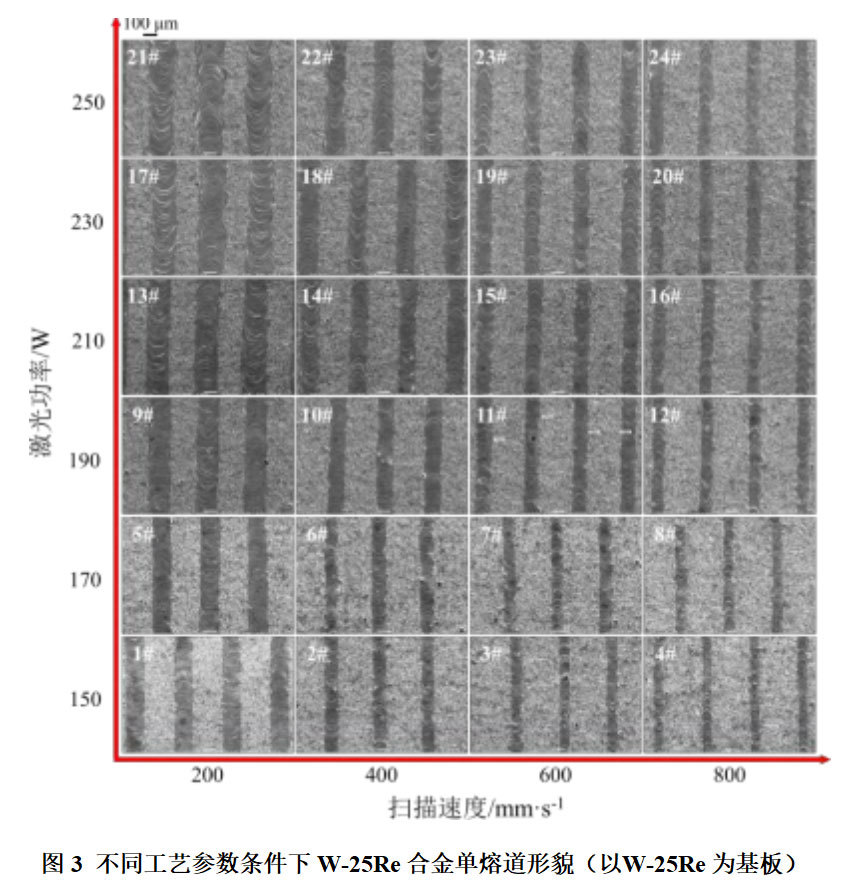

Figure 3 shows the surface morphology results of a single melt channel formed in W-25Re alloy on a W-25Re substrate under different laser power and scanning speed conditions. Using W-25Re alloy as the substrate, where the liquid metal and substrate are homogeneous materials, the W-25Re alloy powder exhibits excellent melting and spreading effects. At laser powers ranging from 150 to 250 W, increasing scan speeds resulted in continuous single melt channels without significant spheroidization. However, the width of the W-25Re alloy single melt channel gradually decreased with higher scan speeds. Under conditions of lower laser power and higher scan speed, the surface of the single melt channel exhibited noticeable undulations.

2.2 Analysis of Substrate Material Influence on Single Melt Channel Spheroidization

Spheroidization is a common defect in SLM-fabricated components, arising not only from droplet splatter during forming but also from the wettability between liquid metal and the substrate [23]. Wettability refers to a liquid's ability to spread on a solid surface. When the solid-liquid-gas interfacial tensions are in equilibrium, the wetting equation is given by [24]:

cosθ = (σsg - σsl) / σlg

where: σ_(sg) is the solid-gas interfacial tension, N/m; σ_(sl) is the solid-liquid interfacial tension, N/m; σ_(lg) is the liquid-gas interfacial tension, N/m; θ is the contact angle, defined as the angle between the gas-liquid surface tension σ_(lg) and the solid-liquid surface tension σ_(sl).

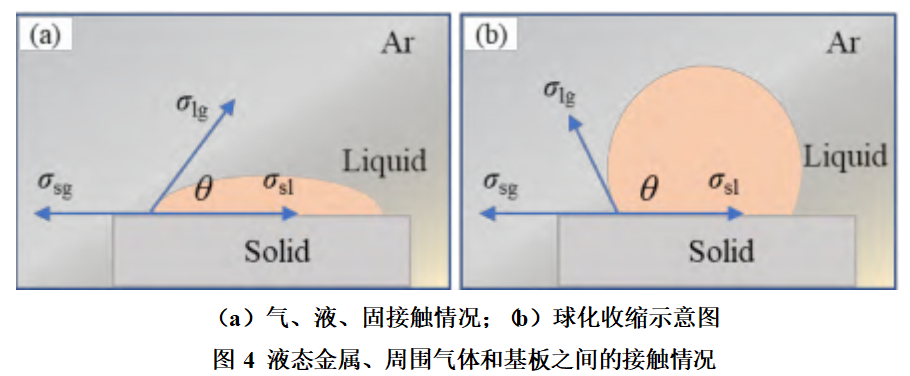

Figure 4 illustrates the contact between liquid metal, surrounding gas, and the substrate. The magnitude of angle θ reflects the degree of wetting of the substrate surface by the liquid metal. Generally, a smaller θ indicates better wettability.

The primary cause of spheroidization is the principle of minimum Gibbs free energy. During solidification of the molten metal pool, surface tension drives the pool to adopt a spherical shape to minimize surface energy. To minimize the total free energy of the system formed between the molten metal surface and the contacting medium surfaces, the molten liquid metal surface tends to contract into a spherical shape under the combined effects of gravity and the gas-solid medium interactions [25]. After laser melting of metal powder, the shape of the molten liquid metal is primarily determined by the contact conditions among the gas, liquid, and solid phases—that is, by the interfacial tensions between the contacting substances. If σ_(sg) > σ_(sl) and 0 < θ < 90°, the resultant force of σ_(sg), σ_(sl), and σ_(lg) points outward from the melt pool. The molten liquid metal tends to spread over the solid surface, exhibiting good wettability, as shown in Figure 4(a). If σ_(sg) < σ_(sl) and θ > 90°, the resultant force of σ_(sg), σ_(sl), and σ_(lg) points toward the interior of the melt pool. Under the combined effects of interfacial tension and Marangoni convection forces, the liquid surface contracts inward toward the molten metal, forming a spherical shape. In this case, the wettability of the liquid metal on the solid surface is limited, as shown in Figure 4(b).

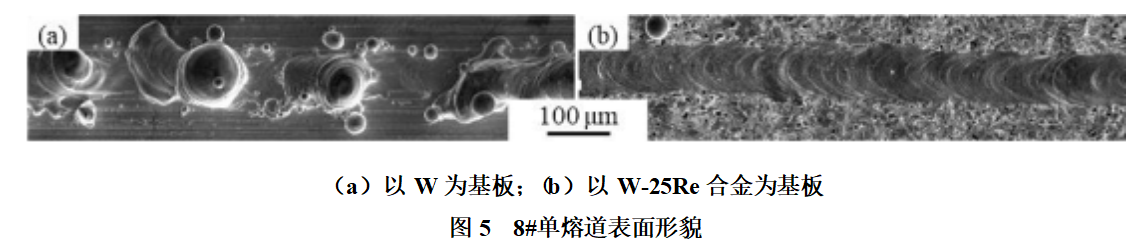

The morphology of a single melt channel formed in W-25Re alloy under process parameters of 170 W laser power and 800 mm/s scanning speed is illustrated in Figure 5. Figure 5(a) shows the morphology of a single melt channel in W-25Re alloy on a W substrate, exhibiting discontinuous channels with severe spheroidization and large spheroid sizes. At this point, the contact angle θ exceeds 90°, indicating poor wettability of the liquid W-25Re alloy on the pure W substrate surface. This occurs because, after heating and melting, the molten W-25Re alloy fails to spread across the pure W substrate. Instead, it bonds with adjacent powder particles, forming discontinuous, large-sized spheres upon cooling, leading to melt channel discontinuities. The spheroidization phenomenon causes poor consistency in melt channel width and height, severely impacting subsequent part forming processes. Figure 5(b) shows the morphology of a single melt channel formed by W-25Re alloy on a W-25Re substrate. The melt channel is continuous with no obvious spheroidization. Since the liquid W-25Re alloy and the W-25Re substrate are homogeneous materials, the contact angle is 0 < θ < 90°, indicating good wettability between them. Therefore, when forming parts via SLM, selecting a substrate material identical or similar to the metal powder material while adjusting process parameters (laser power, scanning speed, etc.) can effectively suppress spheroidization.

2.3 Effect of SLM Process Parameters on Single Melt Channel Width

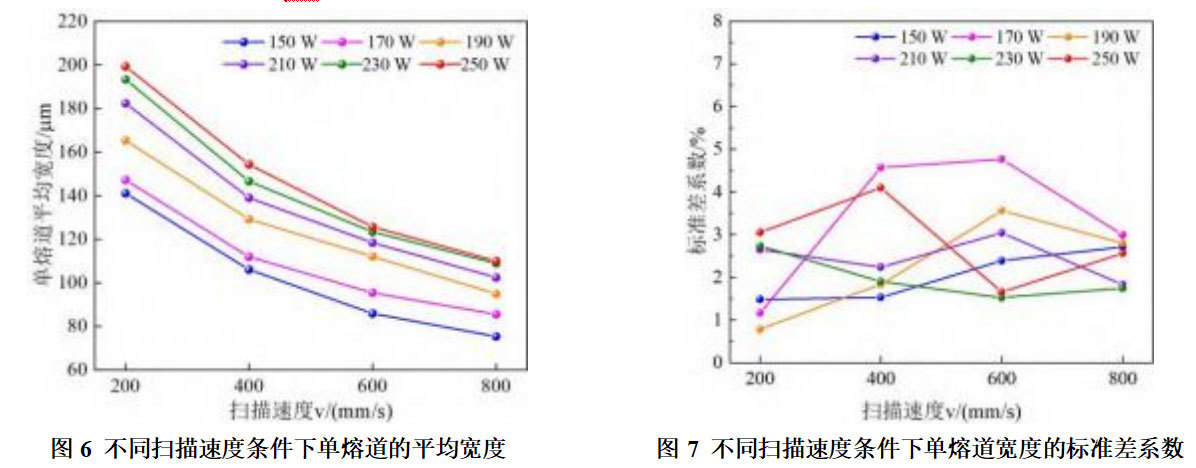

Figures 6 and 7 show the variation in single melt channel width and its standard deviation coefficient of the W-25Re alloy formed on a W-25Re substrate under different scanning speeds. As shown in Figure 6, the width of the single melt channel generally increases with higher laser power; however, it gradually decreases as the scanning speed increases. Increasing the scanning speed reduces the laser exposure time per unit volume of powder, resulting in a lower temperature of the formed melt pool. Due to the high thermal conductivity of the W-25Re alloy, its solidification time is short. Additionally, the poor fluidity of the liquid W-25Re alloy limits its ability to diffuse into the surrounding area. These factors collectively contribute to the reduction in melt channel width. During the formation of the molten pool by laser scanning of W-25Re alloy powder and its subsequent cooling into a melt channel, heat from the molten pool is transferred outward through the substrate and surrounding powder. The heated powder around the melt channel adheres to its sides under the influence of the heat-affected zone, resulting in a melt channel width exceeding the laser spot diameter by 60μm. At a laser power of 150W and a scanning speed of 800mm/s, the single melt channel width reaches its minimum of 75.3μm. At this condition, the minimum melt channel width also exceeds the laser spot diameter.

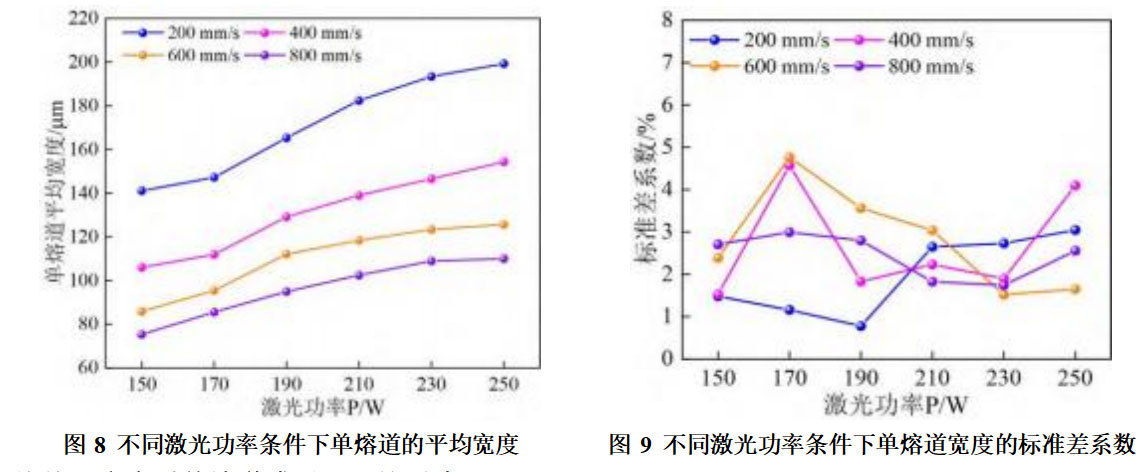

Figures 8 and 9 show the variation in single melt channel width and its standard deviation coefficient for W-25Re alloy formed on a W-25Re substrate under different laser power conditions. Figure 8 indicates that the single melt channel width of W-25Re alloy generally decreases with increasing scan speed, while it increases with increasing laser power. Laser power also influences melt channel width by affecting the temperature of the molten pool. As laser power increases, the temperature of the molten pool formed after W-25Re alloy powder melting rises, enhancing the pool's fluidity and spreadability. Simultaneously, this melts the powder at the pool's edges, thereby increasing the molten pool width. At a laser power of 250W and a scanning speed of 200mm/s, the W-25Re alloy exhibits the maximum single melt channel width, reaching 196.9μm—significantly larger than the laser spot diameter of the equipment.

Figures 7 and 9 indicate that under conditions of 150–250W laser power, 200–800mm/s scanning speed, and W-25Re alloy as the substrate, the coefficient of variation for single melt channel width in SLM-formed W-25Re alloy consistently remained below 5%, substantially lower than the specified 15% threshold. Therefore, the stability of single melt channel width in W-25Re alloy formed on a W-25Re substrate is relatively good. Additionally, the standard deviation coefficient of single melt channel width shows no obvious functional relationship with the single factors of scanning speed and laser power.

2.4 Influence of Line Energy Density on Single Melt Channel Forming Quality

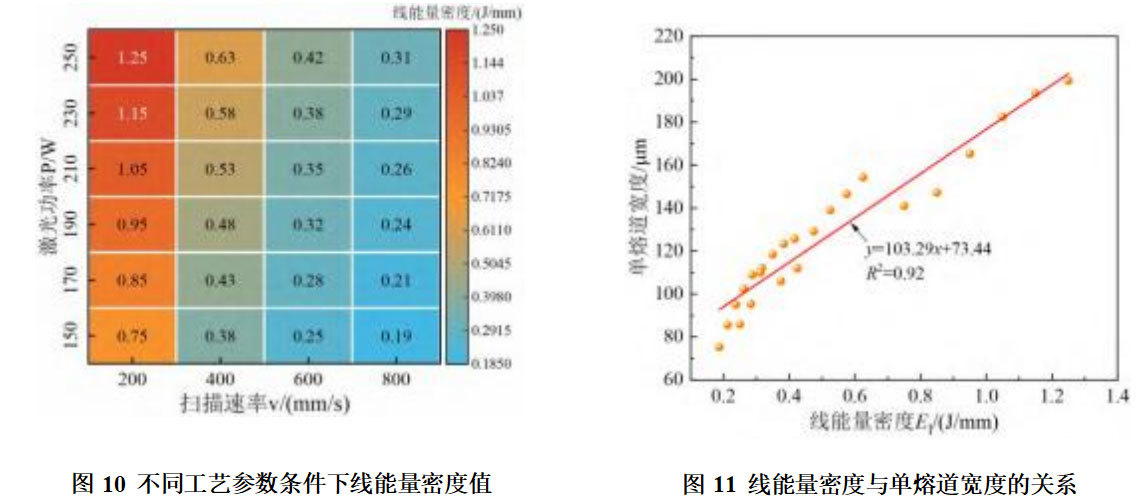

Considering the presence of two variables in this experiment, line energy density (El) was introduced to quantify the energy input during single-pass forming, thereby investigating the combined effects of laser power and scanning speed. The formula for calculating line energy density El [26] is: El = P/v. Here, El represents line energy density (J/mm), P denotes laser power (W), and v indicates scanning speed (mm/s).

Figure 10 shows the corresponding line energy density values for the selected process parameters in the experiment. Linear fitting was performed on the single melt channel width values obtained under different line energy density conditions, as shown in Figure 11. The test data points are uniformly distributed on both sides of the fitted line. The single melt channel width y exhibits a clear linear relationship with the line energy density x, with the relationship expressed as:

y = 103.29x + 73.44

where: y is the single melt channel width, μm; x is the linear energy density, J/mm. As shown in Figure 11, the single melt channel width increases with the increase in linear energy density input.

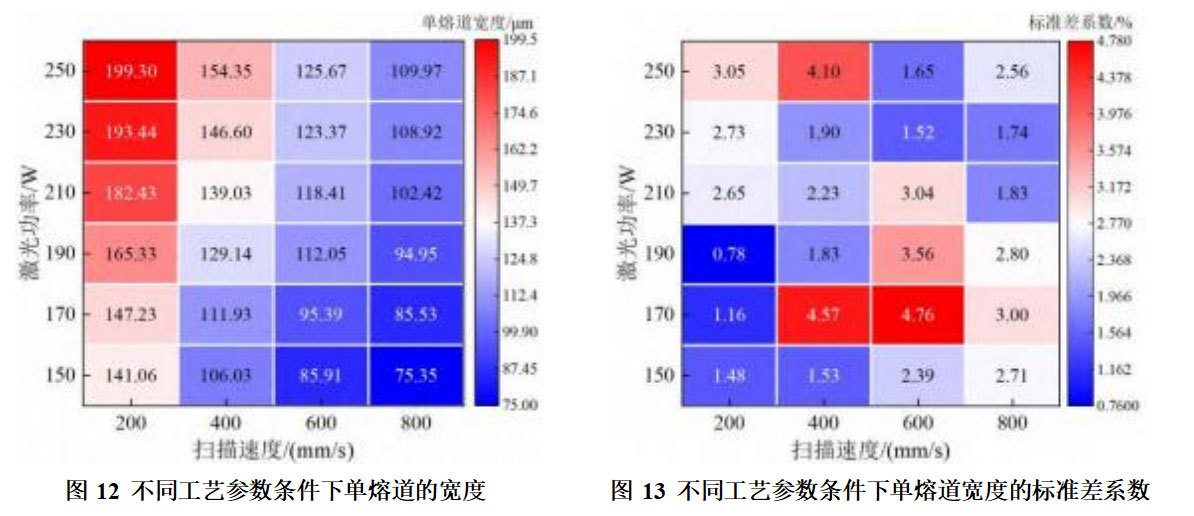

To further analyze the relationship between single melt channel width and standard deviation coefficient with process parameters and identify an optimal parameter range, the width and standard deviation coefficient of single melt channels formed under various process conditions were statistically analyzed, as shown in Figures 12 and 13. Figures 12 and 13 reveal that larger single melt channel widths predominantly occur in the high-power, low-scanning-speed region, while smaller widths are concentrated in the low-power, high-scanning-speed region. The standard deviation coefficient for single melt channel width is minimized primarily in the region where laser power ranges from 170 to 190 W and scanning speed is around 200 mm/s.

3 Conclusions

(1) During single-melt-channel forming, laser power, scanning speed, and substrate material all influence the morphology of the single melt channel. When laser power ranges from 150 to 250 W and scanning speed from 200 to 800 mm/s, the overall quality of W-25Re alloy single melt channels formed on a W-25Re alloy substrate is superior to that formed on a pure W substrate.

(2) Using W-25Re alloy as the substrate, the width of the W-25Re alloy single melt channel generally increases with higher laser power but decreases with increased scanning speed. At 250W laser power and 200 mm/s scanning speed, the single melt channel width reaches its maximum of 196.9 μm, significantly exceeding the laser spot diameter of the equipment.

(3) The single melt channel width y formed on W-25Re alloy substrates exhibits a linear relationship with line energy density x, described by the equation: y = 103.29x + 73.44. The coefficient of variation for melt channel width consistently remained below 5%, indicating excellent stability.

(4) Larger single melt channel widths predominantly occur in the high-power, low-scanning-speed region, while smaller widths are concentrated in the low-power, high-scanning-speed region. The smallest standard deviation coefficient for melt channel width is primarily observed in the region where laser power ranges from 170 to 190 W and scanning speed is around 200 mm/s.

Therefore, based on the relationship between single melt width y and line energy density x, along with the standard deviation coefficient, the width and stability of the single melt can be predicted. This provides guidance for selecting the practical experimental process parameter window.

Reference: Chinese Library Classification: TG669; TG146.21 Document Code: A Influence of Process Parameters on the Characteristics of Single Melts in Selective Laser Melting of W-25%Re Alloy

Stardust Technology's spherical W-25Re alloy powder is produced using radiofrequency plasma spheroidization technology. It exhibits high sphericity, smooth surface finish, absence of satellite particles and significant porosity defects, controllable particle size distribution, low oxygen content, excellent flowability, and high bulk and tapped densities. Benefiting from the properties of tungsten-rhenium alloys, it also exhibits outstanding high-temperature stability and strength. This powder meets the requirements of processes such as selective laser melting and is widely used in high-end fields including aerospace, defense, and nuclear industries.For more product information, please contact our Manager Cathie Zheng at +86 13318326187.

News