Preparation and Performance Characterization of Spherical Mo-Re Alloy Powder for 3D Printing

Release time:

2025-09-25

Mo-Re alloys significantly improve the inherent brittleness and irradiation embrittlement of Mo due to the pronounced “rhenium effect,” enhancing the alloy's machinability and weldability. They represent highly promising advanced reactor candidate materials for cladding, heat pipes, and structural components [1-4]. Due to the high melting point of Mo-Re alloys, powder metallurgy is typically employed for billet preparation; however, the resulting billets often exhibit elevated oxygen content. While vacuum electron beam melting can significantly remove impurity elements, the resulting Mo-Re alloy exhibits coarse grain structure and brittle grain boundaries, making it highly susceptible to defects during hot pressure processing. Additionally, the high hardness, elevated melting point, and severe work hardening of Mo-Re alloys make subsequent processing challenging, resulting in significant material waste.

Rapidly advancing metal 3D printing technologies can address challenges faced by traditional Mo alloy processing methods—including Mo-Re alloys—in achieving complex geometries and ultra-fine grain structures [5-8]. These technological advancements impose higher demands on powder characteristics such as sphericity, flowability, bulk density, and oxygen content [9-11]. The PREP (Plasma Rotary Electrode Pulverization) technique employs a high-temperature plasma gun to melt the end face of a rapidly rotating metal rod. Under centrifugal force, the molten material fractures into droplets that solidify into spherical powders [12]. This method yields spherical powders with excellent sphericity, low porosity, high purity, and minimal impurities, making it the most suitable process for producing spherical powders of refractory metals and alloys.

A spherical powder was prepared using a Mo-Re alloy with a rhenium mass fraction of 14%. The powder's chemical composition, surface morphology, particle size distribution, and physical properties were analyzed and evaluated to provide reference for the application of Mo-Re alloys in additive manufacturing.

1 Experiment

The experimental raw materials comprised Mo powder with an average particle size of 5 μm and purity ≥99.95% (mass fraction), and Re powder with an average particle size <45 μm and purity ≥99.9%. The powder materials were mixed in an 88:12 mass ratio using a SYH-20 three-dimensional mixer. The ball-to-powder ratio was approximately 1:2, with a mixing drum speed of 50 r/min and a mixing time of 4 h. The uniformly mixed powder was loaded into a rubber sleeve and cold isostatically pressed at 200 MPa/min to form cylindrical compacts. These compacts were then sintered into powder metallurgy rods via multi-stage high-temperature hydrogen sintering at temperatures exceeding 2000°C in a horizontal hydrogen medium-frequency furnace. The rod was processed into Mo-Re alloy billets via secondary vacuum electron beam melting combined with vacuum consumable arc melting. The ingots were hot-forged at 1200–1500°C into φ55 mm bars, which were machined into φ50 mm electrodes. Finally, PREP plasma rotary electrode atomization produced spherical Mo-Re alloy powder with particle sizes <150 μm, suitable for 3D printing.

ICP-AES, GD-MS, and TC-600 nitrogen-oxygen analyzer were employed to measure Re content and other impurity elements in the powder. Phase composition of the alloy was analyzed using a Bruker D8 X-ray diffractometer with Cu Kα1 target and X-ray wavelength λ=1.5406 Å. Powder surface morphology was observed using a JSM 6700 scanning electron microscope. Powder particle size distribution was determined by dry sieving using a laser particle size analyzer (GB/T 19077-2016) and a ZBSX-92A mechanical vibrating sieve, followed by weighing. Each sieving cycle lasted 20 minutes, with three replicate measurements averaged. Powder sphericity was determined according to GB/T 21649.2-2017. Bulk density was measured using the funnel method (GB/T 1479.1-2011) with a funnel specification of φ2.5 mm; The mechanical method (GB/T 5162-2021) was used to determine the tapped density, with a weighing range of (50±2) g and a cylinder volume of 25 cm³. The funnel method (GB/T 1482-2022) was employed to assess powder flowability, using a funnel specification of φ2.5 mm.

2 Results and Discussion

2.1 Composition and Phase Composition

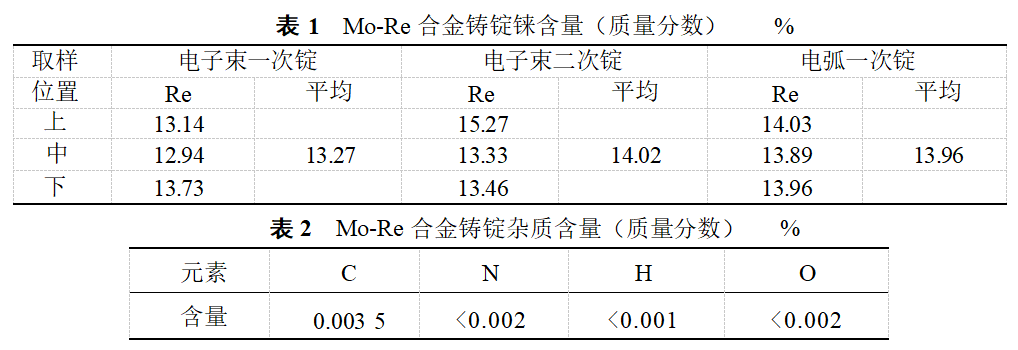

The rhenium content of Mo-Re alloy after electron beam melting and arc melting is shown in Table 1, while the impurity content is presented in Table 2.

The chemical composition of spherical Mo-Re alloy powder is shown in Table 3.

The Re mass fraction in ingots produced from Mo-Re alloy prepared with an 88:12 raw material ratio after two vacuum electron beam remeltings and one vacuum consumable arc remelting was 13.96%. After PREP powder preparation, the spherical powder exhibited a Re mass fraction of 14.08%. The Re content remained essentially consistent, indicating that the volatilization of Mo during melting and powder preparation was as expected, and the elemental ratios in the powder met requirements. Additionally, the C, N, H, and O contents were all below 0.005%, demonstrating exceptionally high material purity. This confirms that employing an appropriate high-temperature hydrogen sintering process, combined with the purification effect of triple melting, yields alloy powders of outstanding purity. Furthermore, spherical powders with the smallest specific surface area at equivalent particle size exhibit superior oxidation resistance.

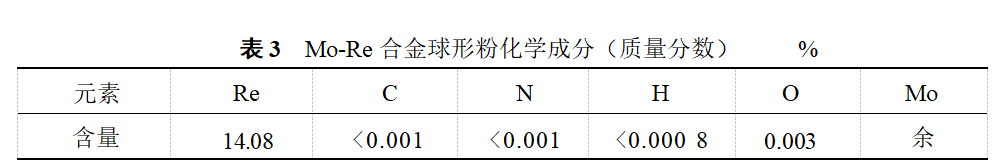

Figure 1 shows the X-ray diffraction pattern of the spherical Mo-Re alloy powder. Analysis reveals a simple phase composition in the diffraction pattern, featuring only characteristic peaks of Mo. No characteristic peaks of compounds related to Mo or Re appear, indicating good solid solution of Re in Mo with no significant precipitation phases. However, compared to the standard Mo diffraction peaks, the peaks corresponding to the (200), (211), and (220) crystal planes all shifted toward higher angles. This shift occurs because Re has a slightly smaller atomic radius than Mo. When Re is solid-solved in Mo, it reduces the interplanar spacing and lattice constant of Mo [13]. According to the Bragg diffraction equation 2dsinθ = nλ, a decrease in the interplanar spacing d at a fixed incident wavelength λ leads to an increase in the diffraction angle θ. This reduction in interplanar spacing induces lattice distortion, which is the primary mechanism for solid solution strengthening in Mo-Re alloys [14].

2.2 Powder Morphology

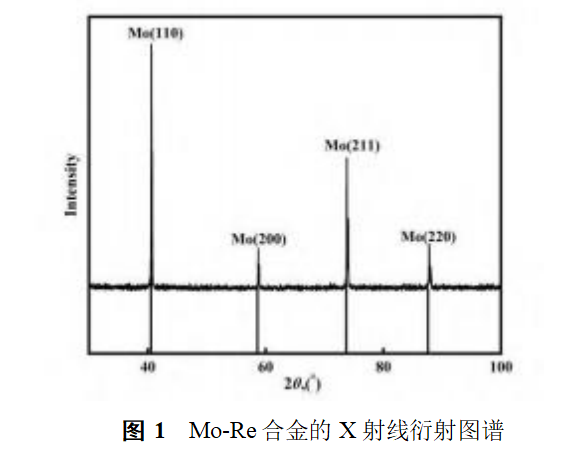

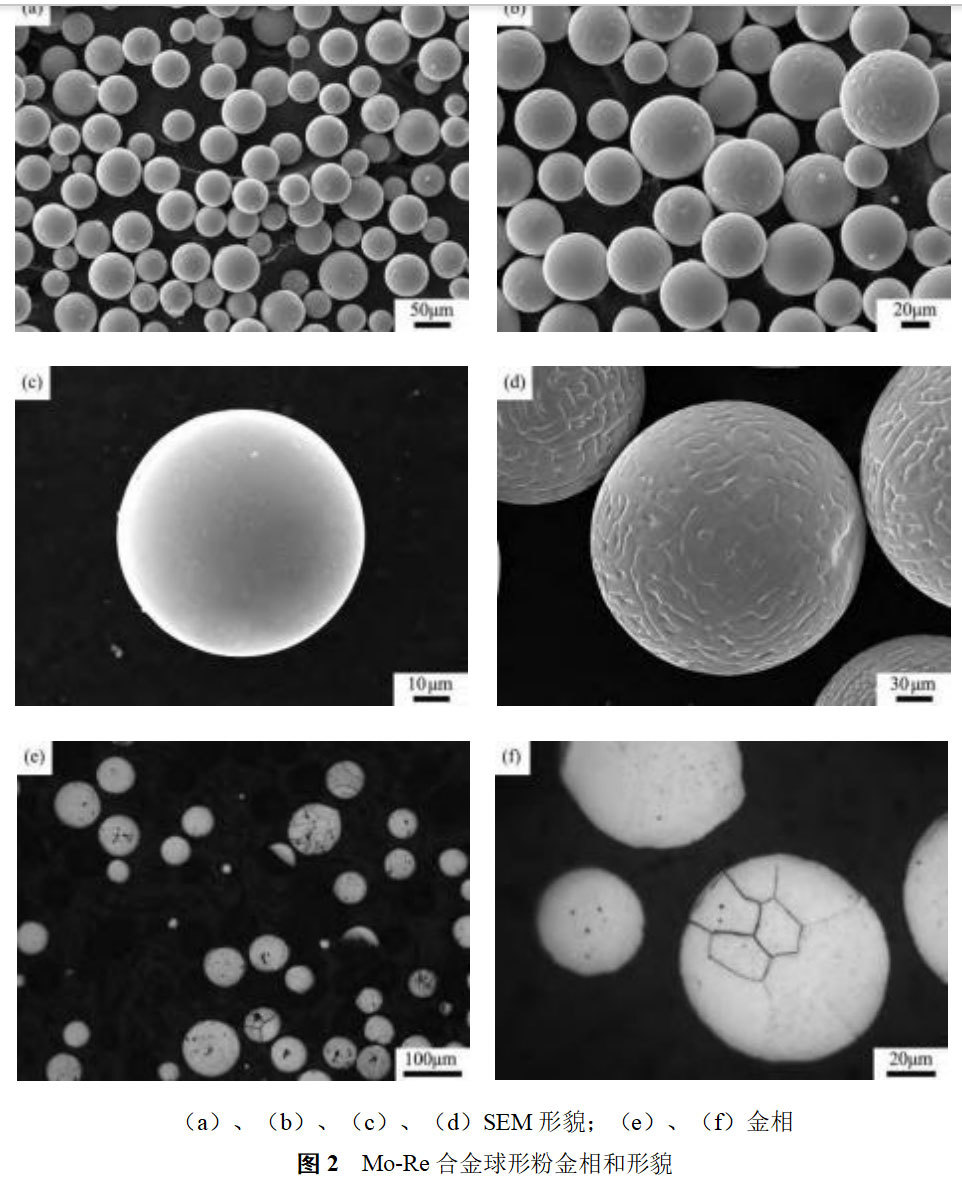

During the preparation of spherical Mo-Re alloy powder, the plasma arc heats the rod material to its melting point. Under the centrifugal force generated by the high-speed rotation of the electrode rod, the molten liquid film breaks into metal droplets. These droplets spheroidize and solidify into powder particles via surface tension during the sputtering process. Consequently, the powder exhibits high overall sphericity, as shown in Figure 2(a) and (b), with a sphericity of 0.979. Furthermore, the powder exhibits minimal hollowness, as shown in Figure 2(e) and (f). However, the high melting temperature creates a significant temperature gradient during cooling. When droplet cooling rates are high or particles are small, solidification and crystallization are suppressed, resulting in minimal surface contraction and good surface finish, as shown in Figure 2(c). Conversely, when cooling rates are low or particles are large, solidification proceeds slowly, leading to pronounced surface contraction and the formation of cellular dendritic structures, as depicted in Figure 2(d).

2.3 Particle Size Distribution

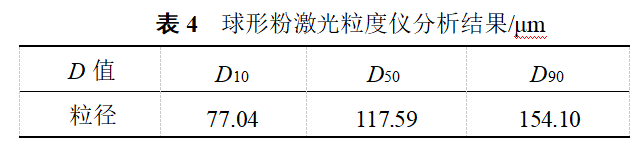

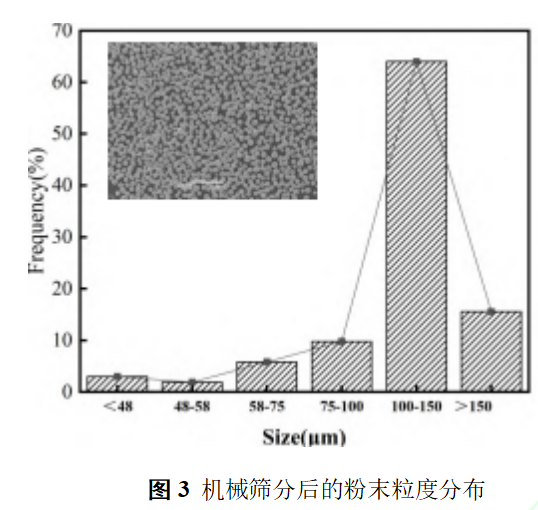

The principle of powder preparation via plasma rotating electrode atomization involves using a high-temperature plasma gun to melt the end face of a rapidly rotating electrode rod. Under the influence of high-speed centrifugal force, the molten material fractures into droplets. These droplets then cool within a protective atmosphere, forming spherical particles through surface tension. Therefore, the particle size of spherical powders is determined not only by the inherent physical properties of the material but also significantly influenced by process parameters such as electrode rod diameter and rotational speed. A larger electrode rod diameter and higher rotational speed result in more effective droplet fragmentation, yielding finer powder particles [15]. However, in actual preparation, the electrode rod diameter and rotational speed are constrained by material strength, processing capabilities, and equipment parameters. The experiment employed a φ50 mm electrode rod. Powder with a D50 of 117.59 μm was obtained at a safe rotational speed, as analyzed by laser particle size analyzer (Table 4). Mechanical sieving was also performed on the powder, yielding the particle size distribution shown in Figure 3, which closely matches the laser particle size analyzer data.

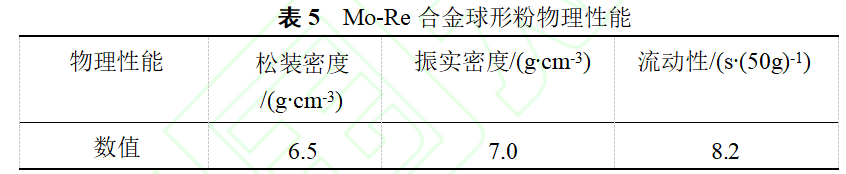

2.4 Physical Properties

The physical properties of the powder are shown in Table 5. Overall, spherical Mo-Re alloy powder prepared using the PREP method exhibits higher sphericity and better bulk density and flowability compared to powders of the same particle size produced by other methods. with superior bulk density and flowability. This makes them highly suitable for powder-based 3D printing technologies such as Selective Laser Melting (SLM) and Selective Electron Beam Melting (EBSM). However, constrained by material strength, density, and the maximum rotational speed of powder preparation equipment, the overall particle size distribution tends to be coarse. The yield of fine particles below 58 μm is relatively low, resulting in higher costs when using this powder for SLM processes. Further enhancing the strength of Mo-Re alloy materials and increasing equipment rotational speeds is expected to yield more fine powders suitable for laser additive manufacturing. Concurrently, by boosting laser power in printing equipment and optimizing processes, coarser powders can be brought within printable particle size ranges, significantly reducing printing costs for Mo-Re alloy selective laser sintering processes.

3 Conclusion

(1) Electrode rods prepared via high-temperature sintering + electron beam melting + vacuum consumable arc melting, combined with PREP rotary electrode atomization, yield Mo-Re alloy powders with high purity (oxygen and nitrogen content below 0.005%) and excellent properties.

(2) The powder exhibits high sphericity, good surface quality, and outstanding physical properties, making it highly suitable for powder-bed fusion 3D printing processes.

(3) The Mo-Re alloy spherical powder prepared by this method has a D50 particle size of 117.59 μm with a relatively large particle size and low yield of fine particles below 58 μm. This makes it suitable for selective electron beam melting processes requiring coarse powders. However, it is relatively costly for selective laser melting. By improving the equipment rotation speed to increase the yield of fine particles and upgrading the printing equipment to accommodate coarser powders, the printing cost of the Mo-Re alloy selective laser cladding process can be significantly reduced.

Reference: DOI: 10.13228/j.boyuan.issn1006-6543.20240172 Preparation and Characterization of Spherical Mo-Re Alloy Powder for 3D Printing

Stardust Technology (Guangdong) Co., Ltd. utilizes its core radiofrequency plasma spheroidization technology to produce spherical molybdenum-rhenium (Mo-Re) alloy powder. The resulting powder exhibits high sphericity, smooth surface, absence of satellite particles, and excellent flowability, featuring uniform particle size distribution and low oxygen content. The Mo-Re alloy itself possesses outstanding high-temperature strength, creep resistance, and corrosion resistance. The addition of rhenium enhances the machinability of pure molybdenum and suppresses carbon and oxygen embrittlement. These properties make the spherical powder highly suitable for advanced manufacturing processes such as laser/electron beam additive manufacturing (3D printing), thermal spraying, powder metallurgy, and injection molding. Consequently, this powder is primarily applied in sectors demanding exceptional material performance, including aerospace, defense, electronic components (e.g., target materials), and medical devices.