Assessment of tungsten for use in the ITER plasma facing components

Release time:

2025-08-05

1. Introduction

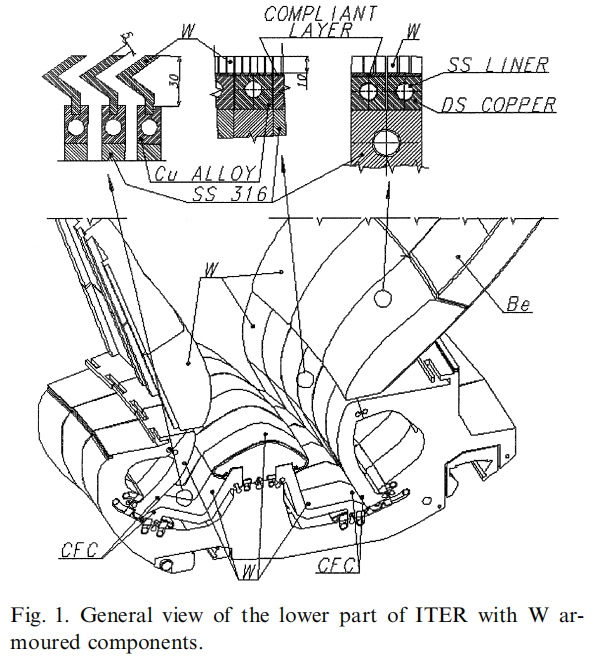

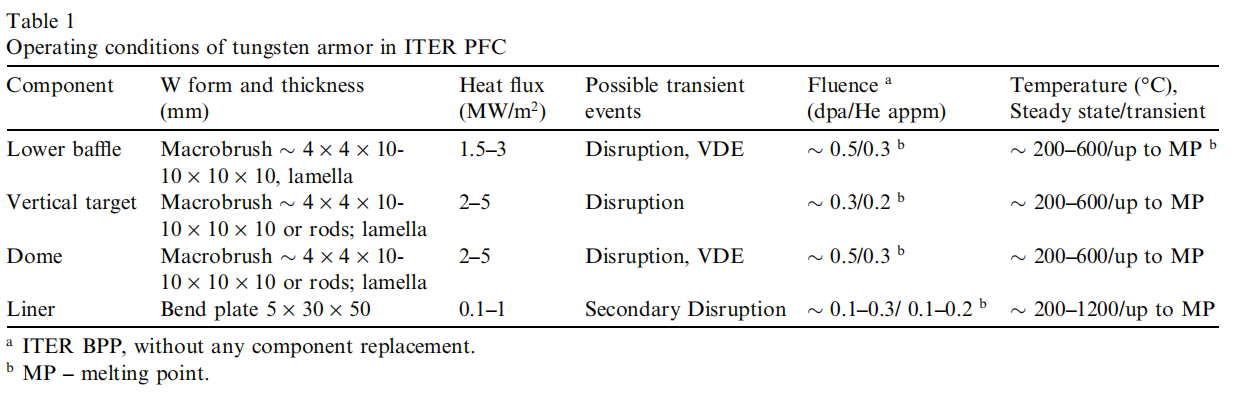

Tungsten has a high energy threshold for physical sputtering (Eth~200 eV for D) and does not form hydrides or co-deposits with tritium. In addition, it has the highest melting point of all metals, the lowest vapor pressure, good thermal conductivity, and high temperature strength. This combination of physical and mechanical properties makes its use as a coating on the high heat ¯ux components very attractive. Fig. 1 shows the regions where tungsten is currently being considered in ITER plasma facing components (PFCs). The tungsten thicknesses being considered range from 4 to 30 mm. Table 1 compares the operating conditions for tungsten in dierent parts of the ITER plasma facing component. From this table it can be seen that the dome and vertical target will receive the brunt of the plasma disruption and, as a result, will need to be on the order of 10 mm thick; while the liner will receive secondary energy from the disruption. The tungsten in the liner serves a dual function. First, behind the liner are the pump ducts. The liner is designed to shield these ducts from the line-of-sight ¯ow of particles, hence the Z shape shown in Fig. 1. The second objective is to have a hot liner surface, on the order of 500±1200°C, to prevent carbon co-deposition in cold areas. Since the heat loads in this area are relatively low (<1 MW/m2), thicker sections are used (on the order of 30 mm) to increase the DT through the aterial. During transient events the surface temperature of tungsten could approach the melting point.

In all of the components shown in Table 1, the tungsten is bonded to an actively cooled copper alloy heat sink and has no structural function. However, possible cracking and delamination could lead to the loss of the energy transfer and, therefore, both have to be avoided. Additionally, tungsten has a large mismatch in coecient of thermal expansion with the copper heat sink. To reduce the thermal stresses, the proper selection of the tungsten armor tile geometry is needed.

2. Analysis of the tungsten database

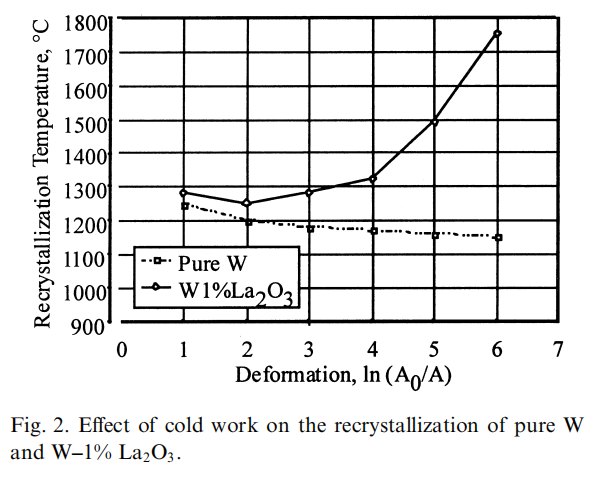

Several types of tungsten arecurrently being considered for ITER application: pure(pressed/sintered/hot-worked),dispersion-strengthened (mechanically alloyed/pressed/sintered/hot-worked),and cast alloy.Pure sintered tungsten produced by powder metallurgy is the most readily available and cheapest grade of tungsten but has a low recrystallization temperature of W-1% LazO3 can be raised considerably,up to more than 17oo°C in the case of thin wire. The high recrystallization temperature of W-1% LazO3 shown in Fig. 2 is a result of the interaction of the dispersoids and the dislocations during the thermome-chanical treatment the higher the amount of hot work,the finer dispersoid particles are formed during annealing. During recrystallization, these particles prevent secondary grain growth. Also W-1% LazO alloy has significantly higher mechanical strength in the recrystallized condition in comparison with pure W.

Cast tungsten is a relatively new product. In the past cast tungsten, because of its large grain sizes, has typically been too brittle to process into sheet or plate.However, the Russian Federation has recently developed a weakly alloyed tungsten (W-Mo-Y-Ti) designated as W-13I. This material is produced by vacuum melting and then cold deforming. The addition of reactive elements such as yttrium and titanium reduces the amount of free oxygen and carbon, resulting in improved mechanical properties.All three of these materials show the pronounced ductile-to-brittle transition typical for tungsten and other bcc metals. For the considered materials the ductile-to-brittle transition temperature (DBTT) is well above room temperature and ranges between 250°C and 600°C.

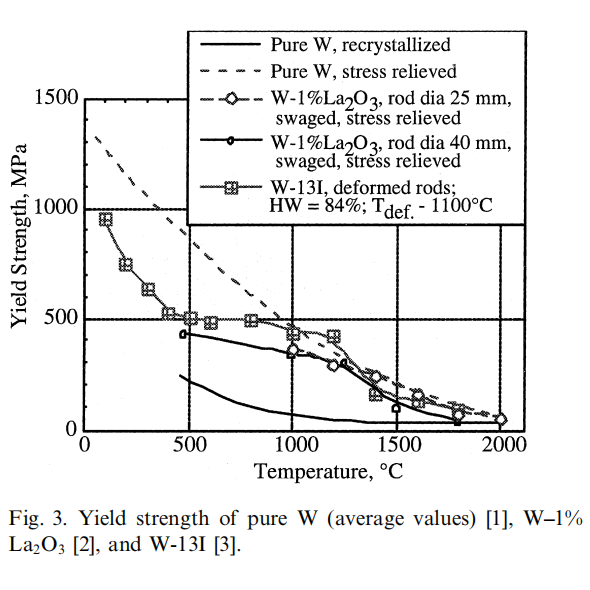

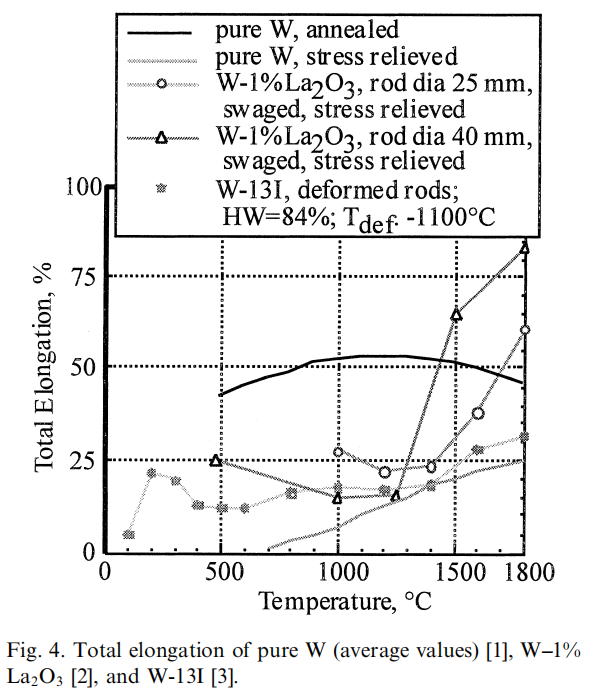

The mechanical properties of tungsten are a function of the production history, alloying elements, impurities,and thermomechanical treatment. This dependence can be seen in Fig. 3 [1-3]. The values of pure tungsten in the annealed/recrystallized and in the stress-relieved conditions are the average of measurements performed on different materials with different test methods. From this figure it can be seen that there is a significant difference between the stress-relieved and recrystallized powder metallurgy tungsten. Also the strength of the W-1% LazO3 and W-13I fall between the two conditions. The higher value is likely due to differences in test procedures and the amount of cold work. Fig. 4 shows the data for total elongation of these materials. Pure tungsten in a cold-worked and stress-relieved condition has a higher strength and a lower ductility than recrystallized tungsten. The total elongation of W-1% LazO3 in the stressrelieved condition is higher than that of pure tungsten in the same condition. For temperatures above 140o°C, the differences in elongation are slightly misleading in that some of the stress-relieved materials have recrystallized while others are partially recrystallized. The important point is that they are all ductile.

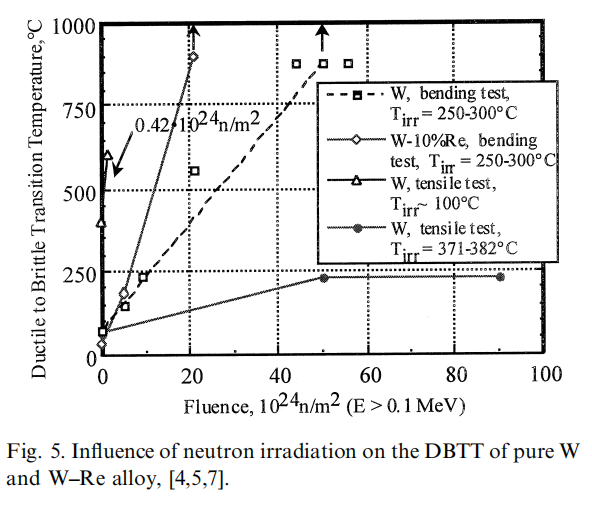

In bcc metals, neutron irradiation typically causes embrittlement. In work done by Alexandrov [4], samples of sintered tungsten were irradiated at 1ooC up to a dose of 4.2 x 1019 n/cm². As typical in low temperature irradiation, hardening and embrittlement were observed.A similar behavior was found by Steichen [5]. In this study tungsten samples were irradiated at 371-380C up to fluence 0.5-0.9 x 10²² n/cm² (~5-9 dpa). Irradiation at this condition again increased the strength and decreased the ductility of material. The decreased ductility was also observed at Tirr and Ttest equal to ~30o°C [6]; the tungsten specimens had brittle fracture at stress levels 5-10 times lower than specimens tested in the unirradiated condition. Fractographic examination of the irradiated specimens indicated that embrittlement is accompanied by a tendency toward subgrain and grain boundary fracture. These data differ from the data reported in [4,5], but the difference can be explained by the different chemical compositions of tungsten alloys used.

To summarize the data on influence of neutron irradiation on mechanical properties of tungsten, the data on DBTT could be used. The magnitude of the increase in the DBTT appears to depend on the fluence and on the irradiation temperature. A comparison of the neutron irradiation influence on pure W and W-10% Re alloy [4,5,7] shows that irradiation leads to a more rapid and severe embrittlement for the W-10% Re aloy (see Fig. 5). The results of this study are somewhat surprising: the alloying element rhenium is effective in sup-

pressing the DBTT to around room temperature and the fabricability and weldability in pure tungsten. Based on this study and similar work in moimproves lybdenum, it appears that, while this alloying element is beneficial in unirradiated tungsten, it is a detriment in irradiated tungsten. This is one of the reasons why rhenium-containing alloys are not being considered for ITER.

3. Unique protection schemes

As discussed earlier, tungsten is bonded to an actively cooled copper substrate. The water inlet temperature to the copper is nominally 140°C. Depending on the heat flux, the interface temperature between the copper and the tungsten can be on the order of 160-20o°C, while the surface of the tungsten can be between 200 and 1200°C (see Table 1). This large variation in temperature can lead to large stresses in the tungsten as a result of differences in the thermal expansion (4 x 10-6/C for tungsten versus 18 x 10-o/C for copper) between the two materials. To reduce these stresses, a variety of fabrication approaches are being investigated.

The first of these methods, referred to as the macrobrush, is being developed by Plansee AG [8]. This approach uses small pieces (4.5 x 4.5 x 10mm) of tungsten with pure copper cast around them. After the pure copper is cast around the tungsten, the copper side of the combination is electron beam-welded to CuCrZr or DS copper substrates. The ombination of the small size of tungsten brush and the surrounding soft-cast copper, which yields easily, lowers the residual stresses at the bond line and in the brittle tungsten. This concept

has been tested in the CEA-Le Creusot high heat flux facility at both 9 and 16 MW/m² for up to 10o0 cycles [8]. During the heat flux test of the EU/Plansee small scale divertor mock-up [8], it was observed that the W 1% LazO3 macrobrush cubes did not recrystallize after 1000 cycles at 18 MW/m², leading to surface melting and a tungsten-copper interface temperature of 800-9oo°C.Cracks in the tungsten between heating periods have not been observed either. A similar approach but with tungsten tile dimensions of 10 x 10 x 10 mm has been applied in Efremov Institute. A small size mock-up with four tiles has survived as many as 2oo0 cycles at 16 MW/m² without damage.

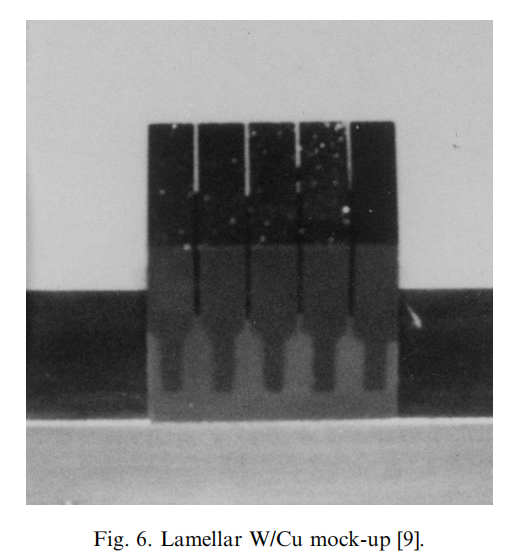

A second approach is to use a lamella-type structure being developed by the Efremov Institute [9]. This approach (shown in Fig. 6) uses 5-mm-thick plates, again with pure copper cast around tungsten plates. The cast combination is then brazed to the copper alloy heat sink using a CuInSnNi filler metal. Again the residual stresses at the bond line are lowered by surrounding the tungsten with a thin layer of soft cast copper. Additionally,casting the copper to the large tab on the tungsten greatly increases the bond surface area. This combina tion was tested at 15 MW/m² and 2150 cycles. Small surface cracks were observed in the tungsten, and the soft copper experienced excessive creep as a result of overheating; however, there was still a good bond at the joint.

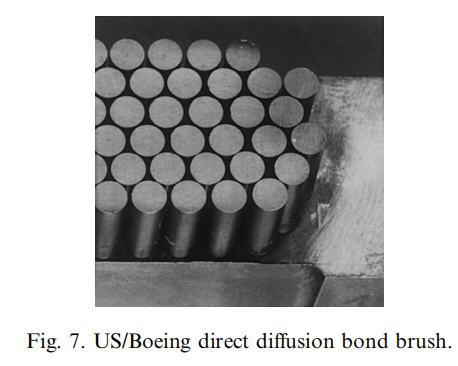

A third approach, which is being pursued in the US,is tungsten brush structure (patent pending), which uses small (1.58-3.16 mm diameter) tungsten welding electrodes and soft copper [1o]. The tungsten is held in place using a welded honeycomb core and is joined to the copper alloy heat sink using low temperature (450-550°C)diffusion bonding of copper to copper (see Fig. 7). In addition to the small size of the tungsten rods and the use of soft pure copper, the low bonding tem perature further reduces the residual stresses. Mock-ups

of the plasma-sprayed and direct diffusion-bonded techniques have been fabricated and are currently undergoing high heat flux testing in the Electron Beam Test Stand at Sandia National Laboratories in Albuquerque,NM,USA.

4. Conclusions

4. Conclusions

Three different tungsten grades have been evaluated for possible use in ITER plasma facing components. Key in material selection are the features of the operational conditions and design requirements for ITER.Generally, there is a very limited database for the tungsten grades within the temperature range of interest to ITER. Therefore, the material selection must be based mainly on limited information. Among the different tungsten grades, W-1% LazO3, W-13I, and pure W in the cold-worked condition are all considered candidates.

For the final selection, additional R&D is needed.Tungsten in the recrystallized condition could not be used because of its low strength, low thermal shock resistance, and high DBTT. Since tungsten grades are brittle in the low temperature ranges of armor operation (unirradiated and irradiated), it seems reasonable to use a form without any possible crack initiators. To avoid loss of material due to delamination, the orientation of the texture (rolling or extrusion direction) needs to be perpendicular to the surface of the tungsten/copper joints. different forms of tungsten (rod, bar, and plate). Each appears capable of reducing the thermal stresses in the tungsten/copper joints. Very preliminary results indicate no delamination of the tungsten during testing and adequate thermal performance of tungsten/copper joints.

Paper citation information

Journal of Nuclear Materials 258-263(1998)308-312

Stardust Technology uses radio frequency plasma to produce spherical tungsten powder, characterized by high purity, low oxygen content, high sphericity, a smooth surface, no satellites, uniform particle size distribution, excellent flow properties, and high apparent density and vibration density.

It is widely used in the following fields:

3D printing: used to produce high-precision tungsten alloy components.

Powder metallurgy: used to produce high-density, high-performance tungsten products.

Electronics: used to produce electronic pastes and electrode materials.

Military: used to manufacture armor-piercing ammunition and high-temperature resistant components.

Medical: used as radiation shielding materials.

http://en.stardusttech.cn/products/24.html

Please contact Vicky Zhang at +86-13318326185 for more information on tungsten and tungsten alloy powders.