Organization modulation and mechanical properties of 6061 aluminum alloy manufactured by arc additive manufacturing

Release time:

2025-08-05

In traditional manufacturing, for complex structures, casting and forging processes are usually costly and inefficient [1-4]. Additive manufacturing technology based on CAD/CAM design, through the discrete stacking principle of layer-by-layer manufacturing entity, can break through the bottleneck of the traditional complex parts manufacturing [5-7]. Compared with traditional material cutting and assembly methods, additive manufacturing has more obvious advantages. ColdMetalTransfer (CMT) is a new type of arc additive manufacturing test means. Compared with the traditional TIG and MIG/MAG processes, CMT has better stability, lower heat input, and more controllable transition of molten droplets. Therefore, CMT has gradually become the main heat source choice in the field of arc additive manufacturing [8-9].

Traditional additive manufacturing materials are mainly steel, aluminum, titanium, etc., among which, aluminum has received extensive attention from researchers due to its low density, good weldability, excellent forming properties, etc. [10-13]. DEREKARK et al. [14] used the DC pulsed GMAW process to prepare the parts, the added wire is 5356 aluminum alloy wire and CT scanning technology to investigate the pore distribution under different through-hole temperature conditions. TAKEYUKIA et al [15] and WANGHJ et al [16-17] investigated the arc additive molding process of 4043 aluminum alloy parts by variable polarity tungsten arc welding. In addition, from Baoqiang et al [18-19] significantly improved the mechanical properties of the material by optimizing the porosity defects, forming dimensions and microstructure. By studying two aluminum alloys, 2319 and 4043, using the AC-GMAW method, it was found that heat input, working environment and wire feeding speed were all key factors affecting the size of the porosity, among which the heat input had the greatest influence, and the use of pure argon gas as a protective gas could effectively reduce the porosity. These studies provide a reference for the application of aluminum alloy in arc additive manufacturing.

6061 aluminum alloy is prone to form ternary eutectic in the welding process due to the presence of multiple elements [20], and the presence of this eutectic makes the solidification temperature interval of the alloy different from that of binary alloys, which may increase the risk of weld root cracking and affect the mechanical properties of the material. Hammering with welding can significantly optimize the stress situation of the weld, reduce stress concentration, and can reduce weld defects such as porosity, but also improve the organization to refine the grain, which is a good way to deal with the weld channel. At present, there are fewer research reports on combining aluminum alloy additive with follow-welding hammering, so this study adopts the arc additive manufacturing method to study the organization and mechanical properties of 6061 aluminum alloy, and incorporates electric hammering and manual hammering techniques to improve the organization and mechanical properties, and compares the effects of the two types of hammering methods on the weld channel, with the aim of finding out the optimal method of hammering and providing references to related research.

1 Test materials and methods

1.1 Test materials and equipment

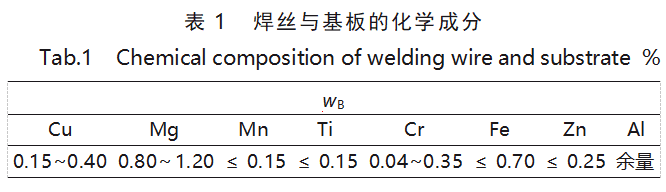

6061 aluminum alloy plate is used as the substrate, and 6061 aluminum alloy welding wire is used as the filler material, whose diameter is 1.2 mm. the size of the substrate is 200 mm × 100 mm × 8 mm. the main chemical composition of 6061 aluminum alloy is shown in Table 1. this study is a single-layer multi-pass test, and the test equipment includes FroniusCMTAdvanced3200 welder, wire feeder, control box, test work platform, welding torch, and with a mass fraction of 99.99% pure argon as a protective gas.

1.2 Test Methods

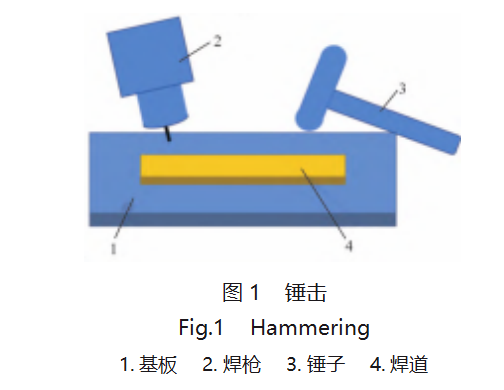

In the pre-treatment stage before welding, the material first needs to be pre-welded to remove surface oil and impurities. Subsequently, a GWS670 angle grinder was used to grind the substrate until the surface was smooth to ensure that the welding was smooth and seamless. After the welding was completed, the specimens were hammered separately to ensure that the height of the torch was raised at a certain level each time, and the magnitude of the applied hammering force was judged based on the height difference of the weld pass. Considering the error in the amount of hammering deformation, the error was reduced by the average value. The hammering position and hammer head size are shown in Fig. 1, and the load is 0.245 N. In the test, the welding speed is maintained at 600 mm/min, the welding current is 100 A, and the interlayer temperature is 100 ℃, and the hammering method is changed (manual, electric, and unhammering), and three weldments are finally obtained.

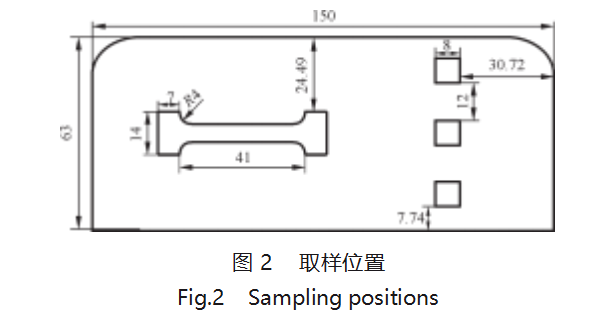

The dimensions of the weldments were measured and the specimens for tensile specimens and metallographic observations were cut by wire-cutting. The sampling location of the specimens is shown in Fig. 2. 3 groups of horizontal tensile specimens with a thickness of 1.5 mm were cut. Each incremental weldment was cut out of the upper, middle and lower 3 pieces of specimens, totaling 9 pieces of metallographic observation specimens. The specimens were first set using a metallographic specimen setting machine, and then sequentially sanded, polished, and blown dry, and the specimens were corroded by selecting Kroll's reagent (the volume ratio of HF, HNO3, and H2O was 1:3:96) for 7 s. After the corrosion was completed, the specimens were observed with an optical microscope of OLYMPUSPX53, and the images were taken and recorded at 200x and 500x, respectively. Subsequently, the observed specimens were polished again, and a high-precision digital microhardness tester was used for Vickers hardness testing, with a loading load of 0.245N, 25s per loading, and each polished specimen was tested in 5 groups in 5 different areas. The size of the tensile specimen is shown in Fig. 2.Finally, the cut 3 groups of horizontal tensile specimens were polished and stretched using WDW-100B universal tensile tester with a tensile rate of 1mm/min, and the tensile data were recorded.

2 Data analysis

2.1 Metallographic histogram analysis

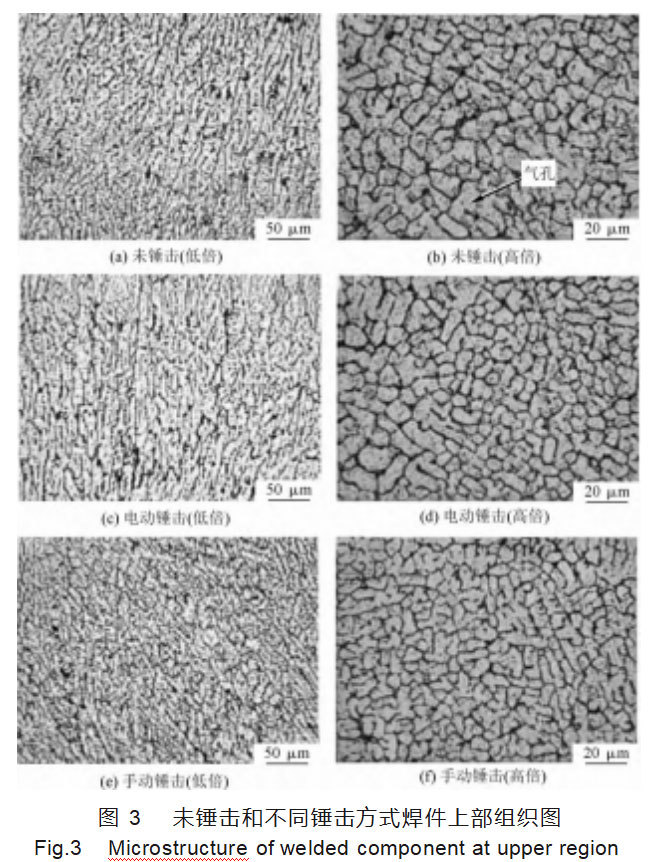

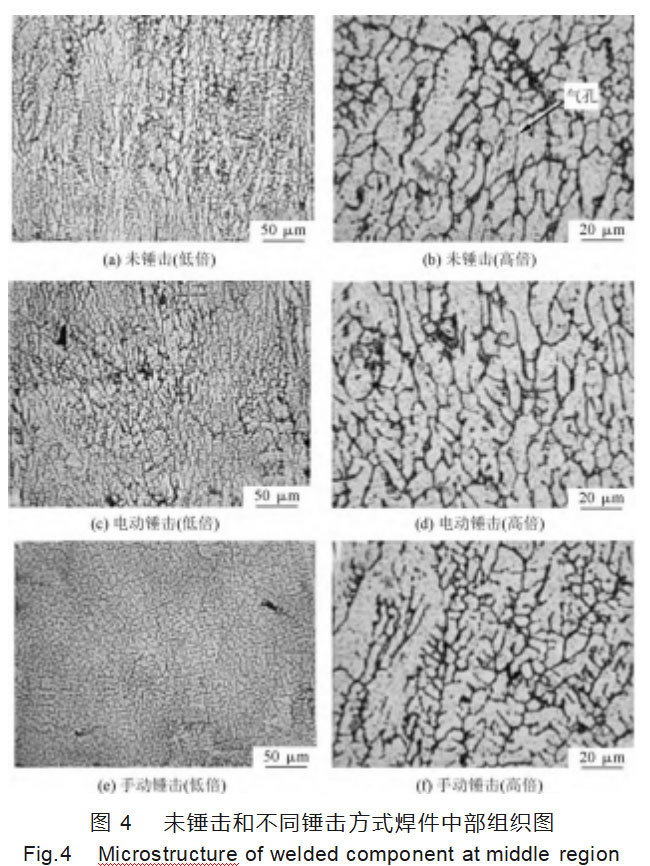

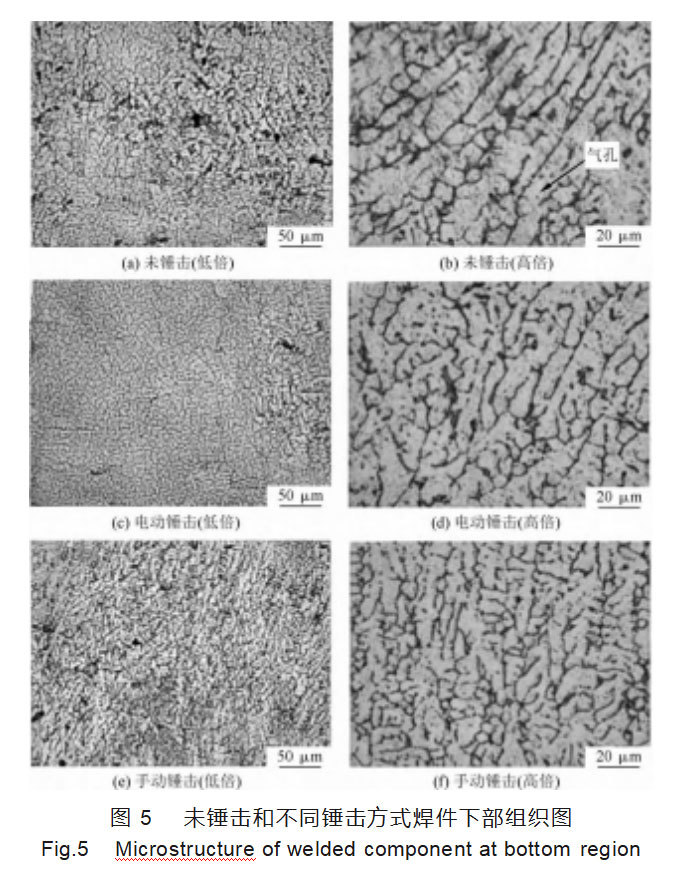

The organization of the upper, middle and lower parts of the weldments with unhammering and 2 types of hammering methods are shown in Figs. 3~5, respectively.

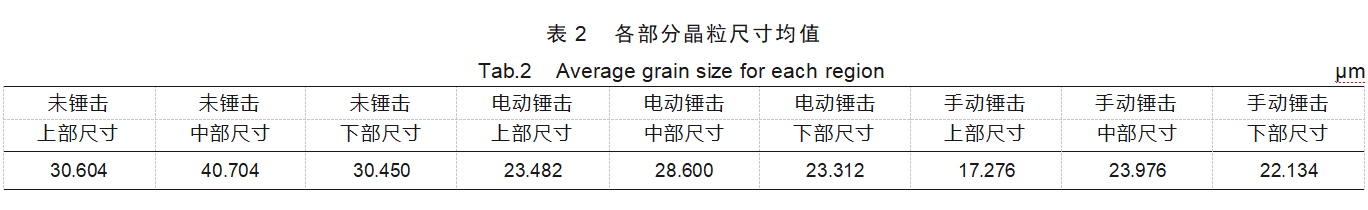

The mean values of grain size at different magnifications of each part of different hammering methods are shown in Table 2.

It can be concluded from the observation of microstructures and analysis of dimensional data that there is a significant difference in the metallographic organization of the additive weldments with unhammering, electric hammering and manual hammering. Among them, the grain organization of the unhammering weldments is coarse, the internal structure is not refined enough, and more defects, such as porosity or cracks, are prone to occur, affecting the mechanical properties of the material. Electric hammering of the weldment grain organization compared to the non-hammering more fine, the structure tends to be uniform, because the vibration brought about by hammering effectively refines the grain, but the effect is not as significant as manual hammering. Manual hammering of the weldment organization is the smallest, grain refinement effect is the best, the weldment of the most uniform metallurgical organization. Manual hammering provided more precise control, leading to more uniform plastic deformation and grain refinement. Weldments under the action of hammering, grain refinement is mainly due to two aspects: one is plastic deformation, hammering to promote the solid-phase region of the metal to produce longitudinal and transverse extension, resulting in grain compression in the process of compression, refinement; two is the vibration effect on the crystallization of crystals, when the weldments are not fully solidified, the vibration generated by hammering to disrupt the crystallization of the molten pool of the crystallographic orientation, dendritic crystals due to the vibration of the breakage of the nucleus, the formation of a more nuclei, which make the grain boundary The area of the grain boundary increases, which enhances the effect of fine grain strengthening. By refining the grain, the strength and toughness of the weldment is improved, and the purpose of enhancing the weld quality is finally achieved. From the microstructure, it can be observed that there are more welding defects, such as porosity, etc., in the non-hammered weldments, while the defects in the electrically hammered weldments are significantly less, and the defects in the manually hammered weldments are the least. The reason for this is that the hammering action increases the denseness of the weld channel and improves the structural properties by compacting the porosity and reducing the defects during the welding process, resulting in a denser organization of the material and a significant reduction in surface defects. This improvement plays an important role in the overall performance enhancement of the weldment.

Morphologically, there are significant differences in the grain size of the weld channel in each layer, with the lower part having the coarsest grains; the middle part having slightly finer grains compared to the lower part; and the upper part having the finest grains. The reason for this difference is that with each layer of additive material, the lower weld channel is heated by the upper weld channel, resulting in an increase in heat input, which contributes to the coarsening of the grains. In addition, since it is more difficult for the lower weld pass to dissipate heat, this further contributes to the coarsening of the grains.

2.2 Hardness data analysis

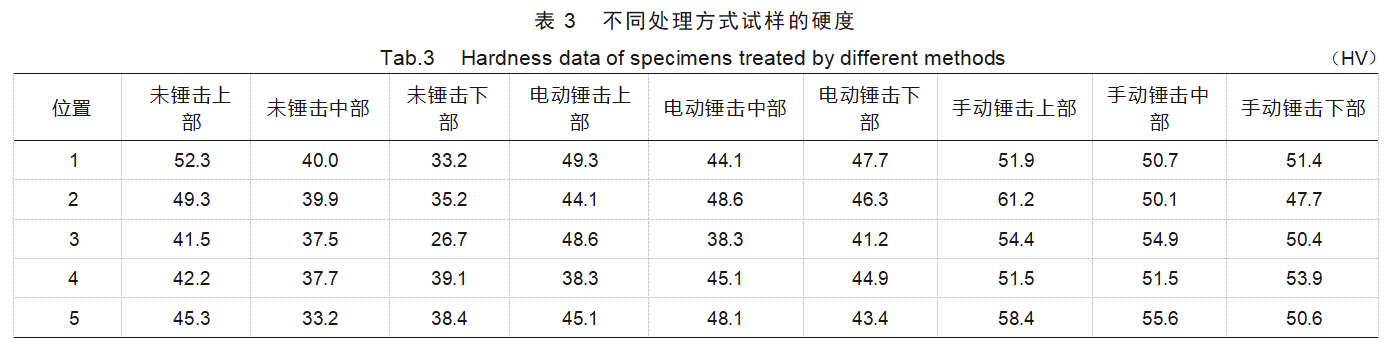

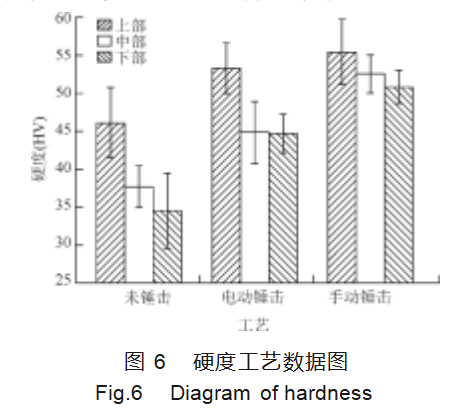

The hardness data of unhammering weldments, the hardness data of electric hammering weldments and the hardness data of manual hammering are shown in Table 3.

The average value of the five sets of data is shown in Fig. 6. It can be seen that the hardness of the weldments with manual hammering is the largest, followed by electric hammering, and the hardness of the weldments without hammering is the smallest. This is mainly due to the plastic deformation of the weld metal by the hammering action, resulting in the continuous movement and accumulation of dislocations. As the dislocation density increases, the dislocations intersect and entangle with each other during the movement, thus increasing the hardness of the material. Manual hammering produces greater plastic deformation and therefore higher hardness of the weldment. Another reason is the effect of grain refinement. The fine grain strengthening effect induced by hammering further increases the hardness of the weldment.

The hardness of the upper part of the weldment is greater than that of the center, and the hardness of the center is greater than that of the lower part. This is because the upper region of the grain is more fine, with the depth increases, the grain is gradually coarsened. The finer grains have a stronger fine grain strengthening effect, so the strength and hardness of the upper region is higher, while the lower region has a weaker fine grain strengthening effect due to coarser grains, resulting in relatively lower strength and hardness.

2.3 Tensile data analysis

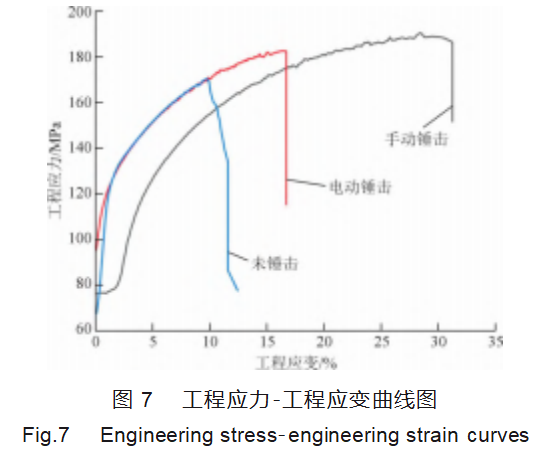

The stress-strain curves of the three groups are shown in Fig. 7. It can be seen that the tensile strengths of the unhammerized, electrically hammered and manually hammered weldments are 170, 182 and 190 MPa, respectively.

The manually hammered weldment specimens have the highest tensile strengths, the best plastics and toughnesses, followed by electrically hammered weldments, and the unhammerized ones have the poorest performance. This is due to the fact that manual hammering results in the finest grain size, and the finer the grain size, the more effective it is in impeding the movement of dislocations, and the more difficult it is for cracks in the material to propagate in each crystal, thus avoiding stress concentrations. Therefore, the grain of the material can be refined by hammering, thus improving the plasticity and toughness of the weldment.

3 Conclusion

(1) 6061 weldments after hammering in different ways, the grain size of the weldments in the order of manual hammering > electric hammering > not hammered, and in the same weldment, the grain size in the order of upper > middle > lower.

(2) The hardness of the weldments also followed the rule of manual hammering>electric hammering>unhammered, and the hardness of the weldments showed the distribution of upper>middle>lower with the change of position. The tensile strength and elongation of the weldments also indicated the same trend.

REFERENCES: CCS TG146.21; TF132 Literature Symbol Code ADOI: 10.15980/j.tzzz.T20240295 Organizational Modulation and Mechanical Properties of 6061 Aluminum Alloys Fabricated by Arc Additive Manufacturing

Stardust Technology (Guangdong) Co., Ltd. is a national high-tech enterprise focusing on the additive manufacturing, powder metallurgy, and surface engineering fields of high-end Stardust Technology (Guangdong) Co. The company's core products include tungsten, molybdenum, tantalum, niobium, chromium and other rare refractory metals and their alloys, which are characterized by high purity, good sphericity and excellent flowability by adopting RF plasma spheroidization technology. The products are widely used in 3D printing, hot isostatic pressing, laser cladding and other advanced manufacturing processes, serving in aerospace, medical equipment, defense and military industries and other high-end fields. The company has the world's leading powder preparation equipment, and through the ISO9001, ISO13485 certification, participated in the development of a number of national and industry standards, is committed to providing customers with integrated solutions from powder preparation to application. For more product details, please contact our professional staff: Cathie Zheng, +86 13318326187.