Effects of Nb and Ta on the Organization and Properties of Nickel-Based High-Temperature Alloys

Release time:

2025-07-30

Nickel-based high-temperature alloys are widely used in aerospace engine turbine discs and turbine blade materials for their high strength and good creep resistance, etc., and their excellent mechanical properties are mainly attributed to the precipitation reinforcement of γ'-Ni3Al (L12 ordered structure) [1-2]. To further improve the mechanical properties of nickel-based high-temperature alloys, the addition of alloying elements has been proved to be a direct and effective strategy [3]. Therefore, it is of great practical importance to study the influence of alloying elements on the mechanical properties of nickel-based high-temperature alloys.

As the main γ' phase forming elements, the increase in the content of elements such as Ta, Nb and Ti contributes to the improvement of the mechanical properties of alloys [4-7]. Xing Pengyu [4] prepared FGH4098 powder high temperature alloy with 101h endurance life at 750°C/690MPa by adding 3.5% Ta (mass fraction, the same below).Shi et al [5] found that the addition of 1% Nb element in nickel-based high temperature alloys (Ni-Co-Cr-Mo-W-Al-Ta-Nb-Re-Ru-Hf-C system) can increase the mechanical properties of the alloys by 1070°C/160MPa. Xu et al [6] based on Nimonic80A alloy, increased the Ti content from 1.80% to 2.25%, and found that the endurance life of the alloy at 750℃/310MPa was increased from 117h to 283h; the Ti content continued to increase to 2.70%, and the endurance life was This is due to the increase of Ti content promotes the formation of Topologically Close-packed (TCP) phase.Xu et al [7] further investigated the effect of Ti/Al ratio on creep properties, and the results show that there is no formation of TCP phase in the alloy when the Ti/Al ratio is 0.74~1.22 and has a high creep life at 750°C/310 MPa. In addition, it has been found that when the Mo/W ratio is low, no TCP phase is formed in the nickel-based high-temperature alloys and the mechanical properties are enhanced [8-9]. Therefore, keeping the Mo/W ratio low and the Ti/Al ratio in a suitable range can avoid the formation of TCP phase and thus enhance the properties of the alloy. Since Ta and Nb are conducive to maintaining the stability of the organization [10], they can achieve the purpose of replacing Ti elements to reduce the Ti/Al ratio, however, the research on the substitution or matching between Ta and Nb elements and Ti elements is not systematic enough, and further research is needed.

Based on the ideal composition of nickel-based high-temperature alloys determined by the “cluster plus connected atoms” model, the microstructure of the alloy after the replacement of Ti by Nb and Ta is investigated in this paper using scanning hardness and compression tests, and the morphology of γ' phase, size and volume fraction of γ' phase, lattice constants of γ and γ' phases, and the lattice constants of γ and γ' phases are investigated in this paper. ' phase lattice constants, γ / γ 'two-phase mismatch, hardness, and mechanical properties were analyzed.

1 Composition design and test method

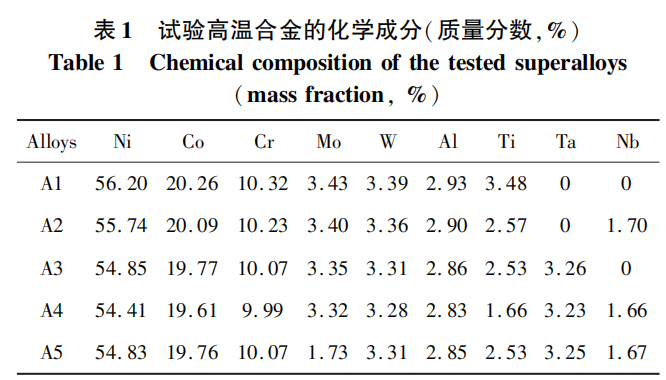

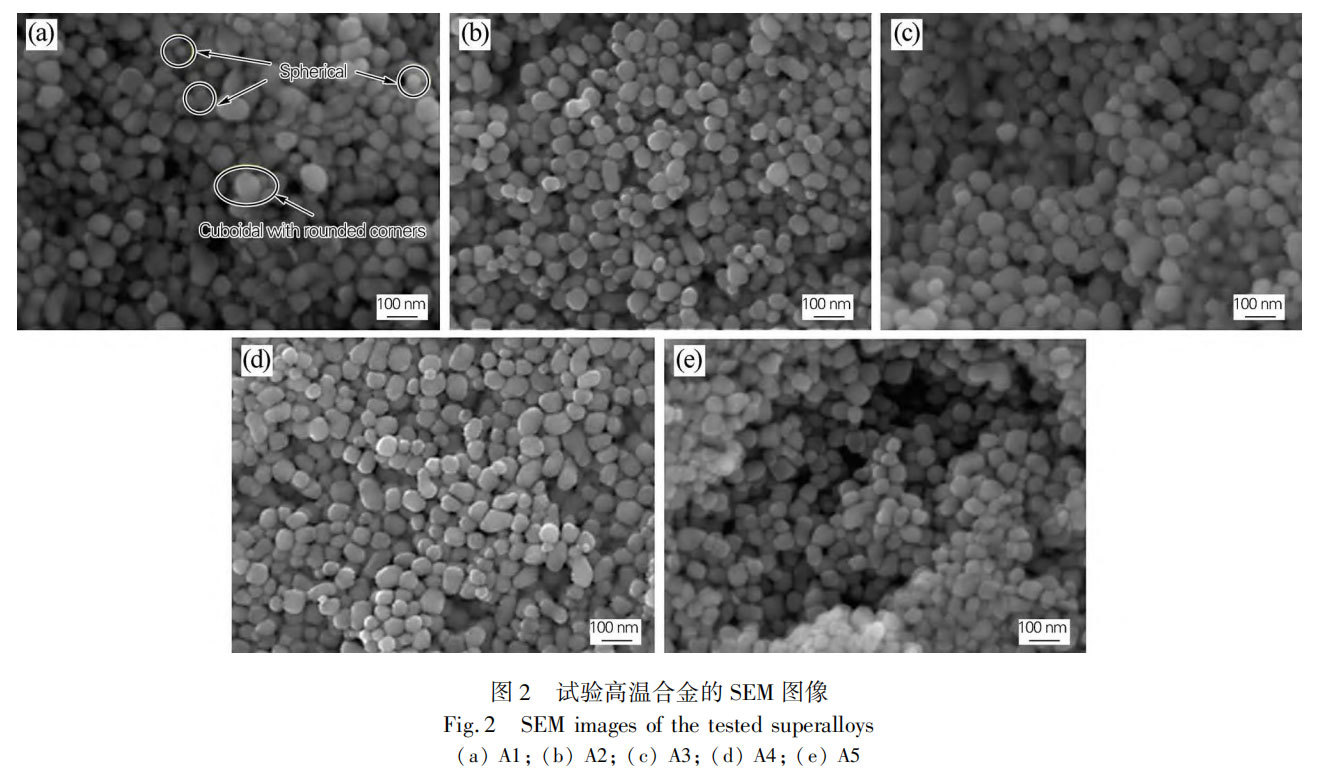

Previous work [11] through the “cluster plus connecting atoms” model to determine the ideal composition of nickel-based high-temperature alloys as [Al-Ni12] (Al, Cr)3, where Ni represents the class of Ni elements (Ni, Co, Fe, Ru), 12 is the number of atoms in the shell layer, Al represents the class of Al elements (Al, Ti, Ti, Ru), 12 is the number of atoms in the shell layer, Al represents the class of Al elements (Al, Ti, Ti), 12 is the number of atoms in the shell layer. Al elements (Al, Ti, Ta, Nb), Cr denotes Cr-like elements (Cr, Mo, W), and 3 is the number of connected atoms. Firstly, four alloys were designed by replacing Ti with Nb and Ta, which are A1 alloy [Al-Ni8.83Co3.17] (Cr1.83Mo0.33W0.17Ti0.67Nb0Ta0), A2 alloy Al-Ni8.83Co3.17] (Cr1.83Mo0.33W0.17Ti0.50), and A2 alloy Al-Ni8.83Co3.17] (Cr1.83Mo0.33W0.17Ti0.50). Nb0.17Ta0), A3 alloy [Al-Ni8.83Co3.17] (Cr1.83Mo0.33W0.17Ti0.50Nb0Ta0.17), and A4 alloy [Al-Ni8.83Co3.17] (Cr1.83Mo0.33W0.17Ti0.33Nb0.17Ta0.17); secondly, on the Secondly, on the basis of A4 alloy, Ti replaces part of Mo to maintain Ti/Al = 1 while reducing Mo/W = 0.5, and the design obtains A5 alloy [Al-Ni8.83Co3.17] (Cr1.83Mo0.17W0.17Ti0.50Nb0.17Ta0.17). The design compositions of the five alloys are shown in Table 1.

The cast alloys were prepared using a ZGJL-0.025 vacuum induction melting furnace to obtain 100 g. All five alloys were solid-solution at 1200°C for 2 h and then water-cooled, followed by aging at 800°C for 8 h and then air-cooled. A Bruker D8AdvAnce X-ray diffractometer (XRD, CuKα radiation, λ = 0.15406 nm) was used to characterize the alloys in physical phase, and the lattice constants of γ and γ' phases were obtained based on the split-peak fitting of the (111)-plane diffraction peaks of the alloys by the Pesudo-Voigt function γ mismatch (δ) [15-17]:

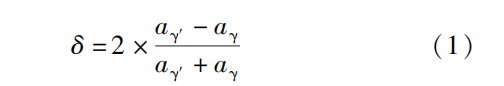

where Aγ and Aγ' are the lattice constants of γ and γ' phases, respectively. Electrolytic corrosion was carried out using JSM-IT800 high-resolution field emission scanning electron microscope (SEM) into H3PO4 + 90 mLH2O) at a voltage of 7.5 V for 7-10 s. The NAnomeAsure and ImAge-ProPlus6.0 shape parameters were calculated from Eqn. (2) using NAnomeAsure and ImAge-ProPlus6.0 parameters [18-19]:

where: η is the shape parameter (0 ≤ η ≤ 1), η = 0 indicates that the γ' phase is completely spherical, and the larger η indicates that the γ' phase is more inclined to cubic; A indicates the length of the parallel plane of the particle; B indicates the longest distance in the particle that is perpendicular to the parallel plane, and the schematic diagram of the calculation of the shape parameter is shown in Fig. 1.

The hardness of the alloy was tested by using HVD-5IS type Vickers hardness tester, and the specimens were polished before the test, in order to reduce the error, each specimen was measured 10 times to take the average value, the loading load was 5 kg, and the loading time was 15 s. The compression test was carried out by utilizing the UTM4204X type universal testing machine for the specimens with the size of ϕ3 mm×5 mm at room temperature, and the compression rate was 0.5 mm /min.

2 Test results and discussion

2.1 Effect of Nb and Ta on microstructure

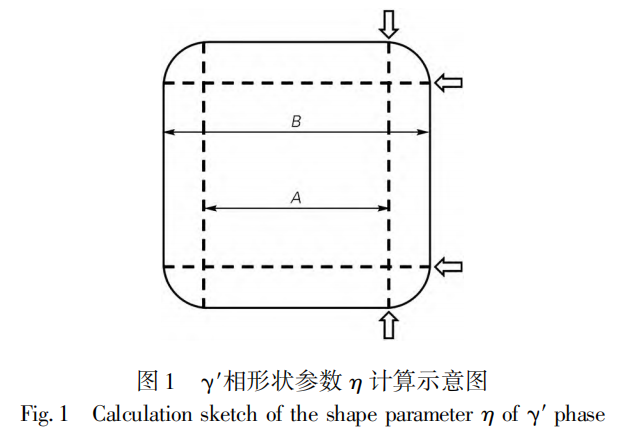

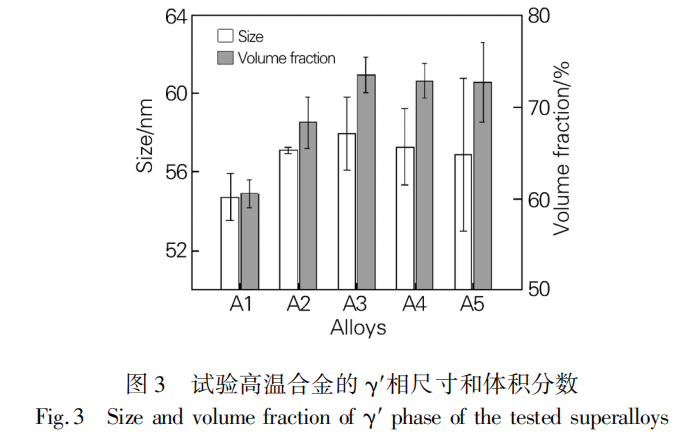

Fig. 2 shows the SEM images of alloys A1 to A5, and Fig. 3 shows the corresponding γ' phase size and volume fraction statistics. From Fig. 2(A), it can be observed that when Ta and Nb are not added, most of the γ' phases in A1 alloys are in spherical morphology (see circles shown). Some of the γ' phases are in a kind of spherical to cubic transition stage, presenting a cubic morphology with rounded corners (see the ellipses shown), when the γ' phases have the smallest size and volume fractions, which are 54.7 nm and 60.5%, respectively. As shown in Fig. 2(b, c), with the addition of Nb and Ta elements, the distribution of γ' phase in A2 and A3 alloys is more uniform, the number of spherical γ' phase decreases, and the number of γ' phase with rounded cubic corners increases, and the sizes of γ' phase increase to 57.1 nm and 58.0 nm, and the volume fractions increase to 68.3% and 73.5%, respectively, when compared with that of A1 alloy. When Nb and Ta elements were added to the alloy at the same time (see Fig. 2(d)), the distribution of γ' phases in the A4 alloy was more homogeneous, and the number of spherical γ' phases was obviously reduced, and the number of γ' phases with rounded cubes was obviously increased, and the size and volume fraction of γ' phases were 57.3 nm and 72.9%, respectively. When Nb and Ta elements are added at the same time and some Mo elements are replaced by Ti (see Fig. 2(e)), the γ' phase in A5 alloy basically appears as a cubic shape with rounded corners, and the spherical γ' phase almost disappears, with the sizes and volume fractions of γ' phases being 56.9 nm and 72.7%, respectively.

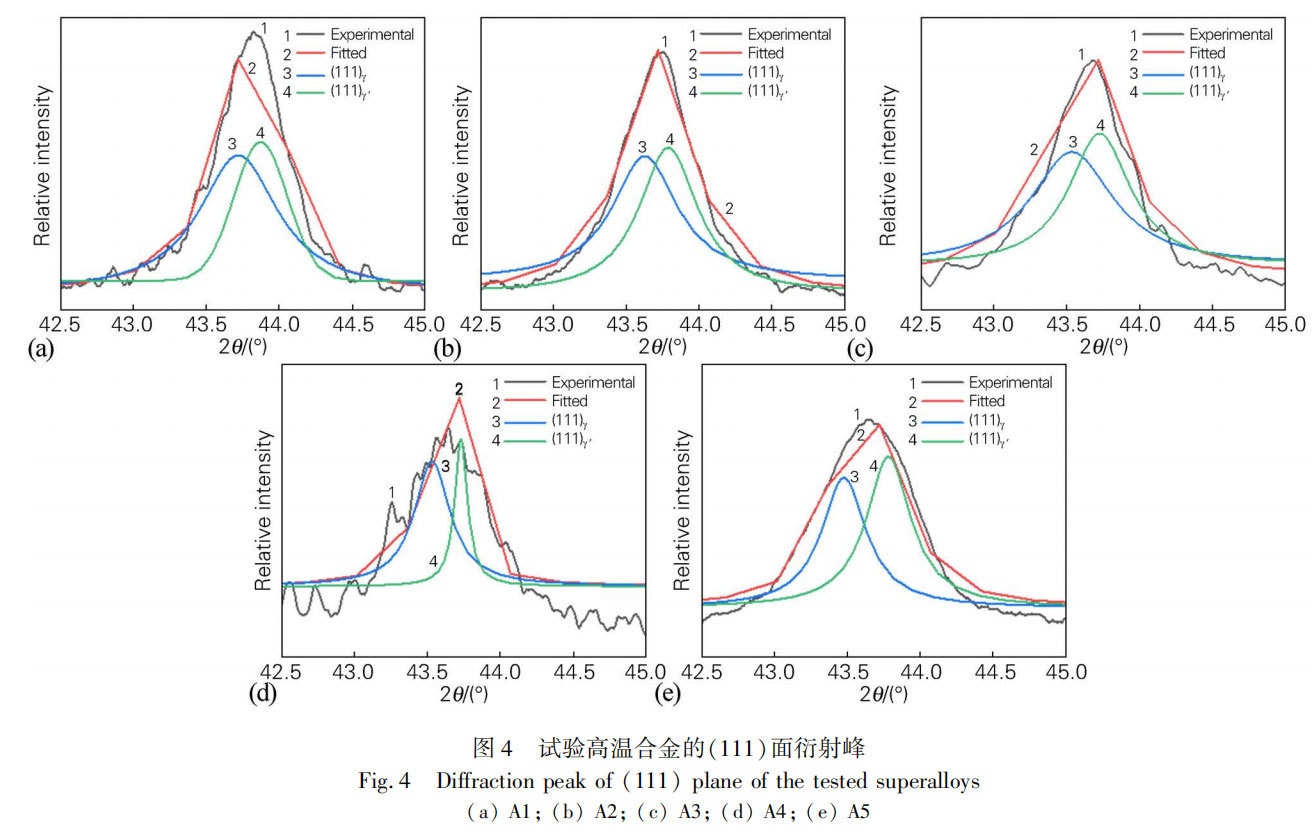

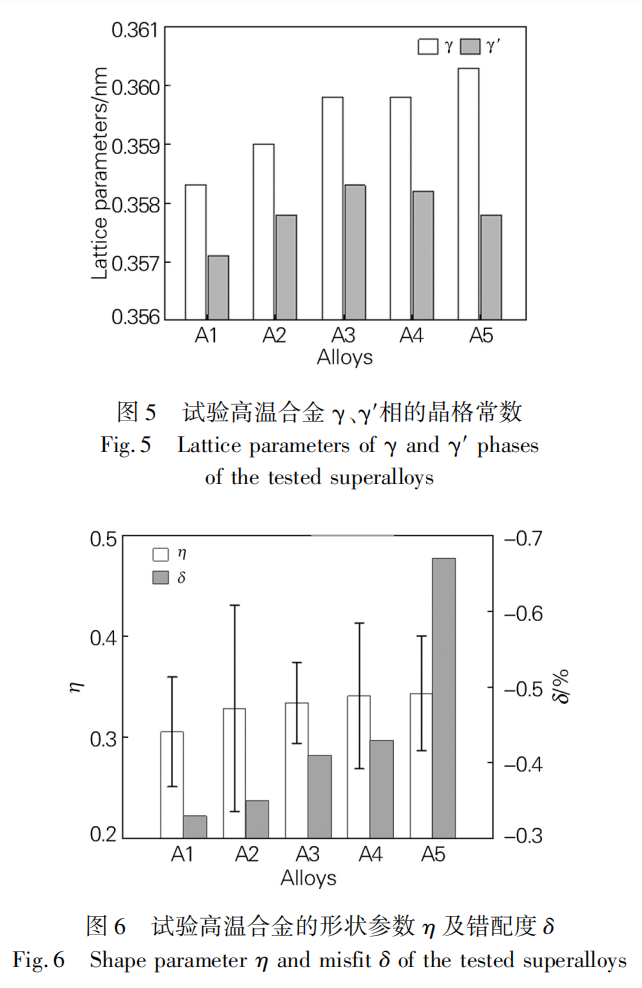

It is found that the morphological changes of γ' phase are closely related to the mismatch degree [20], when the absolute value of the mismatch degree is small, the interfacial energy plays a major role, making the γ' phase morphology appear as a sphere; while when the absolute value of the mismatch degree is large, the strain energy is dominant, which contributes to the transformation of the γ' phase morphology to a cubic shape. Therefore, in order to investigate the change of mismatch degree of A1~A5 alloys after solid solution aging, the (111) surface was peaked by the method of peak-splitting fitting, as shown in Fig. 4, and the lattice constants of γ and γ' phases were further obtained (see Fig. 5). With the addition of Nb and Ta elements, the lattice constant of the γ phase becomes larger and larger, while the lattice constant of the γ' phase first increases and then decreases. This is due to the fact that Nb and Ta have larger atomic radii than Ti, which makes the alloy produce larger lattice distortions, leading to an increase in the lattice constant. However, the simultaneous addition of Nb, Ta elements will promote Cr, Mo, W and other elements to the γ-phase bias [21], whose atomic radii are larger than Ni, which further increases the lattice constant of the γ-phase, making the lattice constant of the γ' phase decrease. Figure 6 shows the shape parameters and mismatch degree of alloys A1 to A5. When Nb and Ta are not added, the absolute value of the mismatch degree of A1 alloy is 0.33%, and the γ' phase is spherical under the effect of interfacial energy, at which time η is 0.305. With the addition of Nb and Ta elements, the absolute values of the mismatch degree of A2 and A3 alloys increase to 0.35% and 0.41%, respectively, which makes the γ' phase morphology begin to change from spherical to cubic, and η correspondingly increases to When Nb and Ta elements are added simultaneously, the absolute value of mismatch of A4 alloy further increases to 0.43%, and the γ' phase with rounded cubic shape increases significantly, with η reaching 0.341. When Nb and Ta elements are added simultaneously and part of Mo element is replaced by Ti, the absolute value of mismatch of A5 alloy reaches the maximum of 0.67%, and γ' phase is basically in the form of rounded cubic shape. is basically in the form of a cubic shape with rounded corners, and the spherical γ' phase almost disappears, at which time η reaches 0.344.

2.2 Influence of Nb, Ta on the mechanical properties

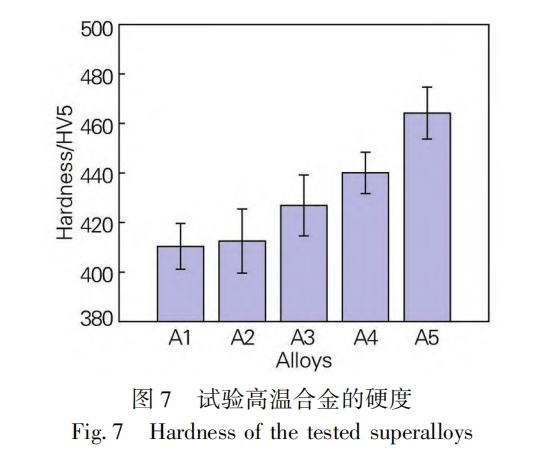

The hardness statistics of the alloys from A1 to A5 are shown in Fig. 7. From Fig. 7, it can be seen that Ta, Nb substitution of Ti elements have increased the hardness of the alloys. When Nb and Ta are not added, the hardness of A1 alloy is the smallest, which is 410 HV5. With the addition of Nb and Ta elements, the hardness values of A2 and A3 alloys are increased to 413 HV5 and 427 HV5, respectively. when Nb and Ta are added to the alloys at the same time, the hardness value of A4 alloy is greatly increased to 440 HV5 compared with that of A1 alloys. the simultaneous addition of Nb, Ta elements and replacing some Mo elements by Ti, the hardness value of A5 alloy reaches the highest value of 464HV5.

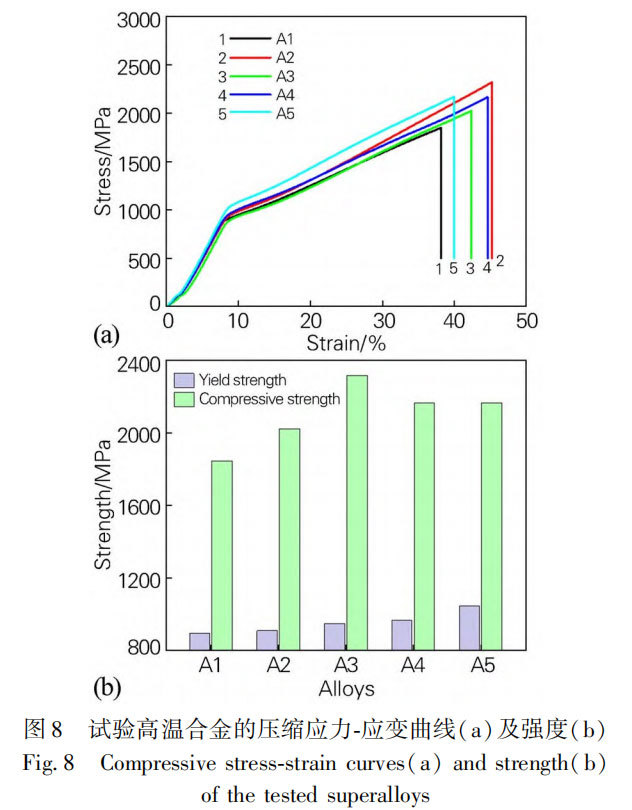

Fig. 8 shows the compressive stress-strain curves and the yield strength and compressive strength of A1 to A5 alloys at room temperature. It can be found that the compressive properties of the alloys are all improved after the replacement of Ti elements by Ta and Nb, especially the yield strength is regularly increased. For A1 alloy, when Nb and Ta are not added, the alloy has the smallest yield strength (892 MPa) and the smallest compressive strength (1847 MPa). With the addition of Nb and Ta, the yield strength of A2 and A3 alloys increased to 907 MPa and 947 MPa, respectively, and the compressive strength increased to 2023 MPa and 2319 MPa, respectively; the yield strength of A4 alloy increased to 964 MPa with the simultaneous addition of Nb and Ta; the yield strength of A5 alloy increased significantly and reached 964 MPa with the simultaneous addition of Nb and Ta and the replacement of some Mo elements by Ti. With the simultaneous addition of Nb and Ta elements and the replacement of some Mo elements by Ti, the yield strength of A5 alloy is greatly increased and reaches the maximum value of 1043 MPa.

The mechanical properties of nickel-based high-temperature alloys are closely related to the size and volume fraction of the γ' phase, because a larger volume fraction of the γ' phase enhances the precipitation strengthening effect of the alloy and improves the mechanical properties [22-23]. On the one hand, the addition of Nb and Ta elements increases the size and volume fraction of γ' phase, which makes the alloy have a strong precipitation strengthening effect, leading to the increase of alloy hardness and compression properties. On the other hand, the addition of Nb and Ta elements also affects the mismatch degree of the γ/γ' phases, and the increase in the absolute value of the mismatch degree improves the alloy's hindrance to dislocation motion, which is favorable to the improvement of alloy properties. As can be seen from Figure 6, the absolute value of the mismatch degree of the alloy increases with the addition of Nb and Ta elements, and when Nb and Ta elements are added at the same time and part of the Mo elements are replaced by Ti (A5 alloy), the alloy has the maximum absolute value of the mismatch degree of 0.67%, and at this time, the hardness and yield strength of the alloy have also reached the maximum value of 464HV5 and 1043MPa, respectively.

3 Conclusions

(1) With the addition of Nb and Ta elements, the morphology of the γ' phase in the test alloy is transformed from spherical to cubic with rounded corners, and the size and volume fraction of the γ' phase first increase and then decrease.

(2) With the addition of Nb and Ta elements, the lattice constant of the γ phase becomes larger and larger, the lattice constant of the γ' phase increases and then decreases, and the absolute value of the mismatch degree becomes larger and larger.

(3) The hardness and yield strength of the test alloy increase with the addition of Nb and Ta elements, and when Nb and Ta are added at the same time and some of the Mo is replaced by Ti (Ti/Al = 1, Mo/W = 0.5), the alloy has the optimum mechanical properties, and the hardness and yield strength reach the maximum values, which are 464HV5 and 1043MPa, respectively.

References: Deer Chao, et al: Nb, Ta Effects on the Organization and Properties of Nickel-Based High-Temperature Alloys

CCS: TG113.2 Literature Symbol Code: A Article No.: 0254-6051(2025)07-0193-06

DOI: 10.13251/j.issn.0254-6051.2025.07.027

Spherical Tantalum Powder **prepared by Stardust Technology using RF plasma technology** * With high purity (low oxygen and nitrogen content), high sphericity, excellent fluidity, and uniform particle size distribution, it is suitable for 3D printing (e.g., laser selective zone melting SLM), powder metallurgy, and medical implantation, and its biocompatibility is excellent, and it has been applied to orthopedic implants (e.g., intervertebral fusion devices, hip joint prostheses). **Spherical niobium powders** (e.g. C103 niobium-hafnium alloy) are also characterized by their high sphericity, low oxygen content and good high-temperature properties, which make them suitable for use in high-temperature components in aerospace, electronic components and the nuclear industry. Both powders have passed strict process control (such as narrow particle size distribution, no satellite ball) to meet the requirements of additive manufacturing on material flow and densification, and have been verified in the military industry, energy and other high-end fields. For more product details, welcome to contact our professional staff, Cathie Zheng +86 13318326187.