-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Explosive composite of Ta-10W liner and steel pipe section

Release time:

2025-07-29

Ta-10W alloy has the characteristics of high melting point, high high temperature strength and excellent corrosion resistance, and is suitable for high temperature, high pressure, corrosion resistance and ablation resistance working environment. The explosive composite technology is used to make Ta-10W alloy and steel composite to form composite plates or pipes, which can not only give full play to the advantages of Ta-10W alloy, but also reduce costs. This work is a preliminary study on the explosive composite of Ta-10W alloy liner and CrNiMo steel pipe section.

1 Explosive composite parameters of Ta-10W alloy and steel

In order to realize the explosive composite of Ta-10W and steel in round tubes, the optimal process parameters of its composite must be determined by experiment. The process parameters of explosive composite in round tubes are usually obtained by correcting the process parameters of plane explosive composite.

The main process parameters of explosive composite are collision velocity V, dynamic collision angle β and collision point moving velocity Ve. Explosive composite is a complex thermophysical process. Its composite process parameters are related to the properties of the coated materials. For each combination of composite materials, there is a corresponding optimal composite process parameter. According to the limit conditions of the explosive composite process parameters, the "weldability window" of the process parameters can be determined, and then several groups of parameters can be selected for experiments, and finally the optimal process parameters can be determined. This method was used to determine the optimal process parameters for the explosive composite of Ta-10W alloy and steel plate, and the bonding state, strength and depth of the plastic deformation layer, interface composition, etc. of the composite interface were analyzed and studied by means of electronic probe, metallographic analysis, hardness test, shear test, ultrasonic detection and other analytical methods (1.2). On the basis of the explosive composite of flat plate, the explosive composite of steel pipe section was studied.

2 Results and analysis of the explosive composite test of pipe section

2.1 Test materials

Two sizes of steel pipe section samples were used. The size of the thin-walled pipe section sample is ①76 mm×14 mm×56 mm (inner diameter×wall thickness×length), the material is PCrNiMoA steel, and the heat treatment specification is 860℃ oil quenching and 550℃ tempering. The sample size of the thick-walled pipe section is φ120 mm×49 mm×100 mm, and the material is 35CrNi3MoVA, oil quenched at 860 ℃, and tempered at 600 ℃.

The materials used for the composite pipe are Ta-10W alloy and 1Cr18Ni9Ti respectively. Ta-10W composite pipe is made of 0.4 mm thick thin plate bent into a round tube, then welded by electron beam, and vacuum annealed after welding. 1Cr18Ni9Ti is a seamless steel pipe. Its purpose is to determine the effect of the explosive composite charge on the deformation and mechanical properties of the base pipe after composite, so as to finally determine the appropriate base pipe thickness.

2.2 Calculation of explosives and charge

For the parallel-placed explosive composite structure, the detonation velocity Va of the explosive is equal to the collision point moving velocity Vc, so the selection of explosives is subject to the limit condition of the collision point moving velocity V. When Ta-10W and steel are explosively combined, the lower limit of the collision point moving speed Vc is 2345m/s and the upper limit is 3530m/s(1), which requires that the detonation velocity of the explosive used should be between 2345 and 3530m/s.

The explosives used in the test are No. 2 rock ammonium nitrate explosive and No. 2 rock ammonium nitrate explosive with 10% TNT added, and their detonation velocities meet the above requirements. There is currently no accurate calculation method for the amount of explosives in the circular tube. Generally, the thickness of the explosives in the flat plate is calculated based on the charge mass ratio, and then 60% of it is taken as the thickness of the explosives in the circular tube (3).

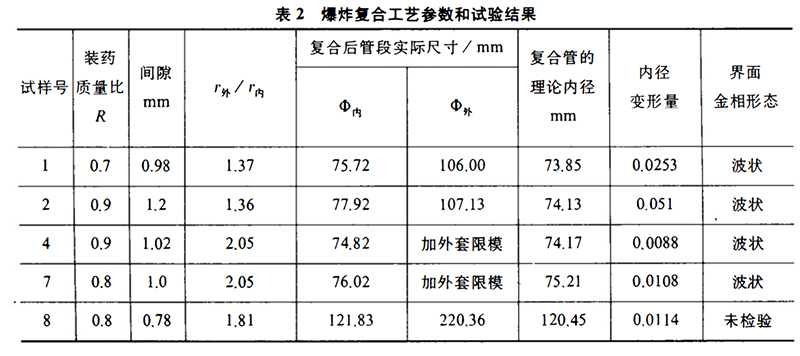

2.3 Explosive compound device for compounding in pipe section

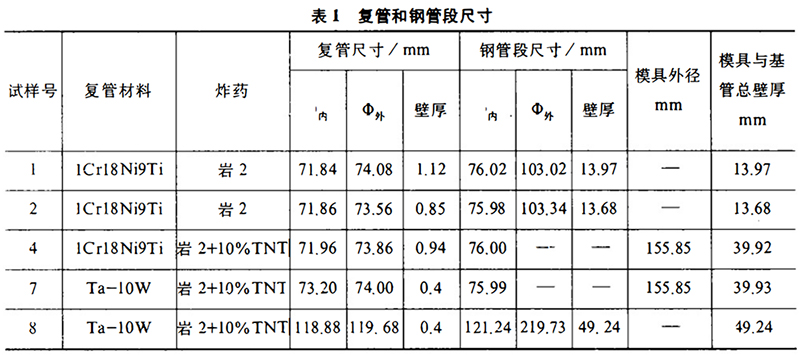

The explosive compound device for compounding in pipe section is shown in Figure 1. According to the relationship between the inner diameter of the barrel section sample, the distance between the composite tube and the inner surface, the charge thickness and the detonation method, the composite tube, buffer layer, explosive, detonator, center column, detonator and positioning ring are prepared, and the various parts are installed according to Figure 1 to carry out the explosive composite operation. Table 1 shows the size of the test sample, and Table 2 shows the test parameters and results. The theoretical inner diameter of the composite tube in the table is based on the assumption that the base tube does not deform radially during the composite process, and the composite tube is evenly composited on the base tube. The thickness after composite is calculated based on the principle of constant composite tube volume to obtain the theoretical inner diameter of the composite tube.

2.4 Metallographic inspection and appearance inspection of composite interface

2.4 Metallographic inspection and appearance inspection of composite interface

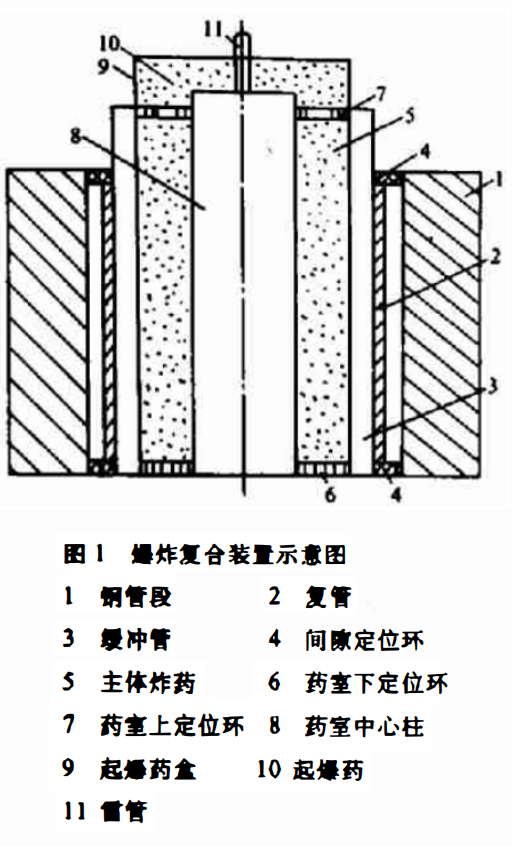

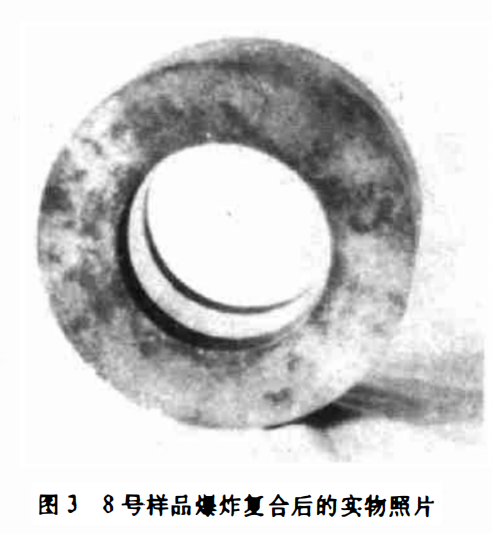

The composite thin-walled tube section is cut longitudinally, and the metallographic sample is taken to inspect the interface bonding morphology. The inspection results show that under the selected test conditions, the composite interface is the desired wavy bond. Figure 2 is a metallographic photo of the composite interface of sample No. 7. This shows that the dry blasting composite process parameters are appropriate and can achieve good composite of Ta-10W liner and steel pipe section. After dry blasting composite, the weld of Ta-10W welded pipe has local cracks, indicating that the elongation of the weld zone is lower than that of the matrix and cannot meet the plasticity requirements during composite. Figure 3 is a real photo of sample No. 8.

2.5 Residual deformation of the inner diameter of the pipe section after composite

Due to the strong impact of the high energy of dry blasting composite on the inner surface of the pipe section, the increase of residual deformation of the inner diameter after composite is inevitable. From the test results in Table 2, it can be seen that when the thin-walled pipe section sample is not added with a mold, the inner diameter deformation after dry blasting composite exceeds 2% and can even reach more than 5%, and the waist drum-shaped uneven permanent deformation is generated. After adding a mold of the same strength grade, [/ increases, and the inner diameter deformation can be controlled at about 1%. For thick-walled composite pipe sections, the rx/rn ratio is 1.81, and the inner diameter deformation is about 1%. The test results show that as the charge mass ratio increases, the inner diameter deformation increases; as the r₄/ra ratio increases, the inner diameter deformation decreases. Therefore, by selecting an appropriate charge mass ratio and r/ra ratio, the inner diameter deformation after compounding can be controlled.

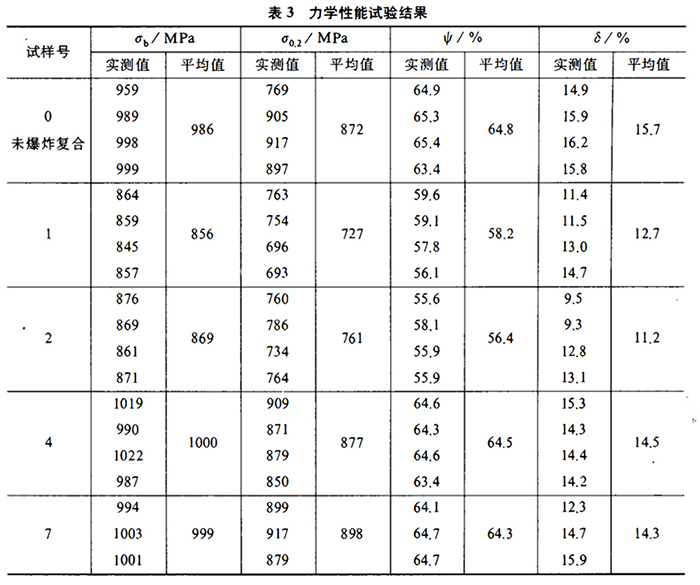

2.6 Changes in mechanical properties of pipe segment materials after dry explosion compounding

In order to analyze the changes in the mechanical properties of the base pipe material before and after explosive compounding, samples were taken along the generatrix from the pipe segment samples before and after compounding to make tensile specimens. The test results are shown in Table 3. From the test results, it can be seen that the inner diameter deformation of samples No. 1 and No. 2 is large after explosive compounding, and their strength and plasticity are reduced, that is, the larger inner diameter deformation leads to the deterioration of the mechanical properties of the base pipe steel pipe segment. If the inner diameter deformation is controlled at about 1%, it will have little effect on the mechanical properties of the pipe segment sample. This result shows that the inner diameter deformation must be controlled when performing explosive compounding of the liner, otherwise the mechanical properties of the base pipe will decrease. 3 Conclusion

3 Conclusion

1) It is feasible to use the modified optimal process parameters of flat plate explosive compounding as the inner compounding process parameters. The thickness of the explosive in the round tube is about 60% of the thickness of the flat composite explosive under the same conditions.

2) Under the condition of charge mass ratio R=0.8, the 0.4 mm thick Ta-10W alloy liner can be reliably laminated in the CrNiMo steel pipe section, and the bonding interface is a wavy bond.

3) Under the condition of ensuring that the steel pipe section has a certain strength and wall thickness, the inner diameter deformation of the composite pipe can be controlled at about 1%, which has little effect on the mechanical properties of the steel pipe section.

Paper citation information

Rare Metal Materials and Engineering Vol. 24 No. 2

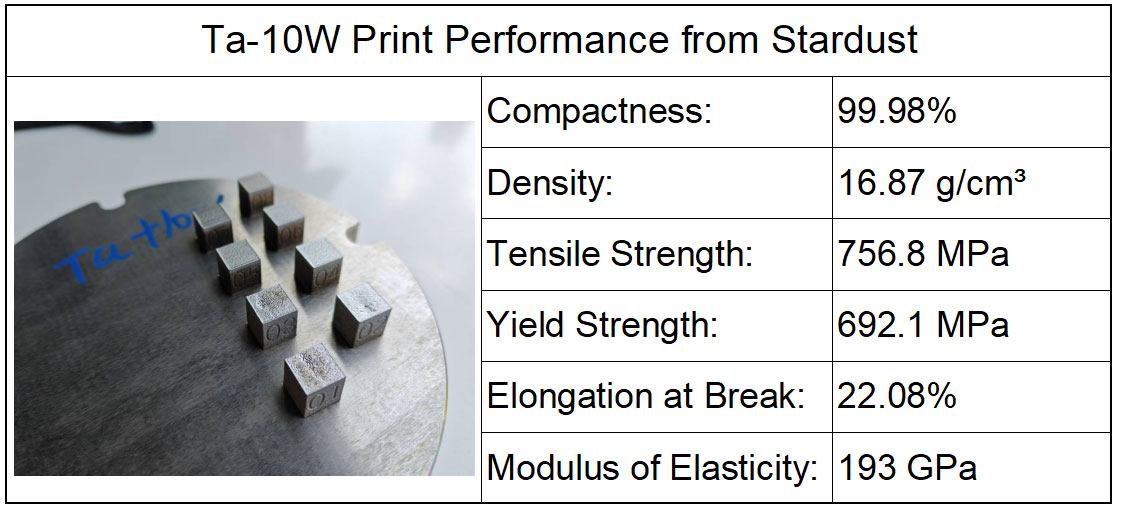

The spherical Ta-10W alloy powder produced by Stardust Technology is made by radio frequency plasma spheroidization process, which has the characteristics of high purity and low oxygen, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flowability, high bulk density and high tap density. Stardust Technology can not only provide high-quality powder materials, but also provide powder printing verification. For more details, please contact Vicky Zhang at +86-13318326185

http://en.stardusttech.cn/products_det/259.html

News

-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Stardust Technology (Guangdong) Co., Ltd.

101, Building 1, Liandong Youzhi Zone, Senshuji Road, Nansha Community, Danzao Town, Nanhai District, Foshan City,Guangdong Pro.,China

QR code