Surface carburizing and high-temperature rolling of HfNbTaTiZr refractory high-entropy alloy

Release time:

2025-06-25

The concept of high-entropy alloys was proposed by Prof. Junwei Ye in 2004, which differs from traditional alloys in that high-entropy alloys have at least five main constituent elements and are mixed in equimolar or near equimolar ratios, with the atomic percentage content of each main constituent element ranging from 5% to 35% [1]. In recent years high entropy alloys have attracted strong research interest from materials scientists due to their unique microstructure and properties [2-4]. Some studies have shown that high entropy alloys have excellent mechanical, irradiation and corrosion resistance, and high temperature thermal stability properties [5-8]. Therefore, high entropy alloys have a broad application prospect in the fields of nuclear industry, aerospace, biomedicine and electronic information [9-11].

The introduction of refractory metal elements can improve the melting point and high-temperature mechanical properties of high-entropy alloys, and then obtain refractory high-entropy alloys [12-13]. The constituent elements of refractory high-entropy alloys mainly include Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, and W, etc. Sometimes, the comprehensive performance of the alloys is regulated by adding non-refractory elements such as Al, Si, and B [14-18]. The bulk refractory high-entropy alloys are mainly prepared by arc melting, induction melting, electron beam melting, mechanical alloying and powder metallurgy, while the thin film samples are prepared by magnetron sputtering and pulsed laser deposition [19-21]. The current research on refractory high entropy alloys mainly focuses on microstructure as well as mechanics, resistance to high temperature oxidation, irradiation and corrosion [22-25].

Although the bottleneck limiting the application of refractory high-entropy alloys is their low-temperature brittleness and ductility, HfNbTaTiZr refractory high-entropy alloys rarely have the advantages of good toughness and high strength at both ambient and elevated temperatures [26-27]. Annealing of this refractory high-entropy alloy at 600 °C and 10 h can significantly improve its hardness [28]. Several studies have shown that different microstructural products (twins, deformation bands, dislocations, microcracks, and grain-boundary holes, etc.) can be obtained under uniaxial compressive deformation conditions at different temperatures (296-1473 K) and strain rates (10-5-10-1s-1) [29-30]. The results of computational simulations show that below the critical temperature of 1298 K the HfNbTaTiZr refractory high-entropy alloy undergoes phase decomposition and tends to form TaNb-rich and HfZr-rich phases with body-centered cubic (BCC) structure, however, at low temperatures the BCC-structured HfZr-rich phases are transformed into close-rowed cubic (HRC) phases. HexagonalClosePacked (HCP) structure [31].Cold rolled samples of HfNbTaTiZr refractory high entropy alloys were annealed at 800 °C for 2 h to obtain TaNb-rich precipitation phases and HfZr matrix phases with two BCC structures [32]. Several studies have revealed that the TaNb-rich physical phase with BCC structure and the HfZr-rich circular precipitation phase with HCP structure have specific crystallographic orientation relations by using 3D atom probe, transmission electron microscopy and X diffraction [33].

Low-pressure vacuum surface carburizing technology is an advanced material surface modification method, the principle of which is to place the heated sample in a carbon-rich atmosphere such as acetylene, after which the carbon-rich gas decomposes on the surface of the sample to form activated carbon atoms, which enter the surface of the sample and then form a surface-strengthened layer with a certain carbon concentration gradient [34-36]. Among the many carburizing treatment methods, low-pressure vacuum carburizing technology has the advantages of uniform carburized layer, adjustable thickness, high density, simple equipment operation, safety, environmental protection, pollution-free and precise temperature control, and so on, so it has been widely used in military and civilian fields [37-39]. Through the surface strengthening treatment of metals and alloys and other materials, not only can maintain the good toughness and plasticity of the matrix, but also enhance the anti-wear and corrosion resistance of the surface, which in turn extends the service life of the material [40-44]. This paper focuses on the effect of surface carburizing treatment on the microstructure and surface hardness of refractory high-entropy alloys with equal molar ratio HfNbTaTiZr.

1 Research Methods

Equal molar ratios of Hf, Nb, Ta, Ti and Zr pure metal powders were melted using a non-self-consuming vacuum arc melting furnace, and the purity of the metal powders was greater than 99.9% (mass fraction). The HfNbTaTiZr refractory high-entropy alloy ingots with good flowability and formability were prepared by homogenizing the alloy ingots by repeated melting and turning the ingots more than five times. A block of 15 mm×8 mm×3 mm was cut from the ingot using a wire-cutting machine, and the surface of the specimen was ground using a series of water-abrasive sandpaper, and then polished using an automatic grinding and polishing machine and a polishing solution with a composition of SiC and a grain size of 1 μm until the surface of the specimen was smooth. The surface carburization of the alloy specimens was carried out in a low-pressure vacuum carburizing furnace with a temperature control accuracy of ±1 ℃, a carburizing temperature of 1500 ℃, a temperature increase time of 6 h, a temperature decrease time of 24 h, a carrier-carrying ratio (the ratio of the carrier gas argon to the carburizing gas acetylene) of 20, and a furnace pressure of 50 Pa. Carburized layers with different phases and thicknesses were prepared on the surface of the high-entropy alloy by controlling the processing time and other parameters. The high entropy alloy specimens were removed from the carburizing furnace when the furnace temperature was reduced to near room temperature. In addition, the deformation of this refractory high-entropy alloy was realized by warm rolling. Before rolling, the alloy ingot was heated to 1000°C in a muffle furnace with a holding time of 10 min, and a total of five passes were rolled, and the thickness of the alloy ingot before and after rolling was recorded for each pass.

The corresponding high entropy alloy specimens were tested using material science characterization techniques. The surface phases of the specimens were examined using a Bruker D8ADVANCE or D2PHASER X-ray diffraction (XRD) instrument. A MERLINCompact or Gemini360 scanning electron microscope (SEM) was used to measure the surface carburization layer or the internal microstructure of the specimens. Before the SEM test, the surface carburized specimens of high entropy alloys need to be prepared for SEM specimen refinement, and the strength of the SEM specimen needs to be controlled during the grinding process to prevent the carburized layer from peeling off. The surface hardness of the specimens was characterized by a FALCON507 Vickers hardness tester, the load was set to 5 kg, and the number of measurements for each specimen was 3. Nano mechanical properties of the alloy were analyzed by using the NanoIndenterG200 in-situ nanomechanical testing system, with the radius of curvature of the Berkovich indenter made of diamond as 20 nm, and the maximal load of the nano indentation test was 25 mN, and the load was 25 mN, and the maximal load of the nano indentation test was 25 mN. The maximum loading load of the nanoindentation test was 25 mN, loading time was 10 s, holding time was 10 s, and unloading time was 10 s. The elemental state of the specimen surface was analyzed using a PHIQuanteraII X-ray photoelectronspectroscopy (XPS) instrument and the sputtering method of the Ar ion beam, the sputtering voltage of the Ar ion gun was 2 kV, and the sputtering area was 2.5 m2 of the Ar ion gun. The sputtering voltage of the Ar ion gun was 2kV, the sputtering area was 2mm×2mm, and the reference sputtering rate corresponding to the SiO2 layer was 10.59nm/min. The full spectrum of the specimen surface was collected after 1min of clean sputtering, and the narrow spectrum of the relevant elements was collected after 5min of sputtering.

2 Results and Discussion

2.1. Calculation and testing of as-cast alloy specimens

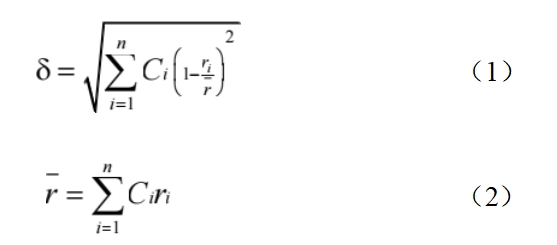

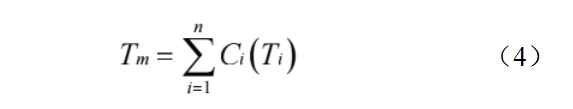

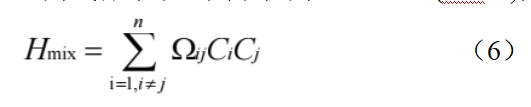

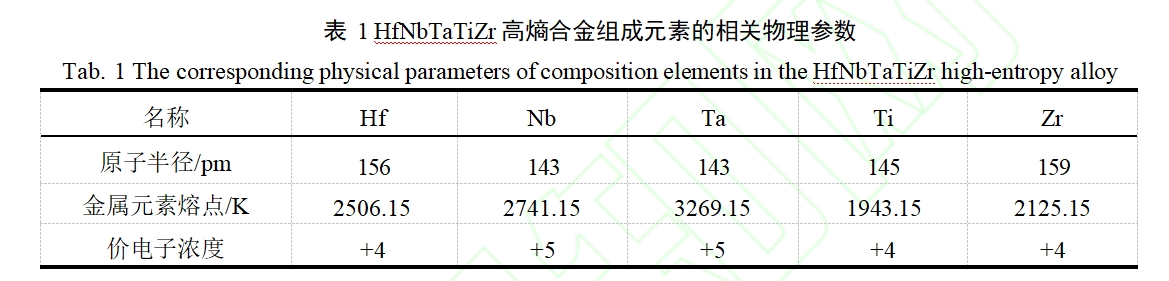

The atomic radius mismatch parameter δ and the solid solution formation capacity parameter Ω are two key parameters for predicting the state of solid solution formation in multi-component high-entropy alloys [45-46]. The atomic radius difference δ = 4.61% and the average atomic radius r- = 149.2 pm for the HfNbTaTiZr high-entropy alloy were calculated by combining Eqs. (1) and (2).The solid solution formation capacity parameter Ω is determined by the theoretical melting point Tm of the alloy, the entropy of mixing ΔSmix, and the enthalpy of mixing ΔHmix, which were calculated by combining Eqs. (3)-(6) [45]. Combining the melting points of the constituent elements of high entropy alloys (Table 1) and Eq. (4) the theoretical melting point Tm of HfNbTaTiZr high entropy alloys is calculated to be 2516.95 K. The entropy of mixing ΔSmix is calculated from Eq. (5) to be 13.38 J/(mol-K).

i denotes the ith constituent element;

Ci denotes the mole fraction of constituent element i;

ri denotes the atomic radius of constituent element i;

Ti denotes the melting point of the ith constituent element;

R is the gas constant with a value of 8.31451J/(mol.K);

Ωij denotes the parameter of the solid solution formation capacity of binary alloying of elements i and j;

Cj denotes the constituent element j molar fraction of the constituent element j.

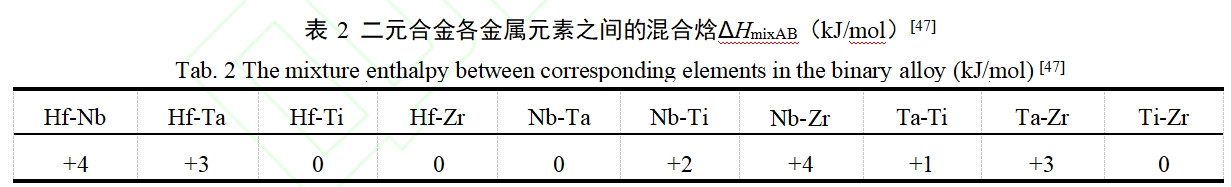

Based on Eq. (6), the enthalpy of mixing of the binary alloy

ΔHmixAB and ΩAB (i.e., Ωij) are derived as shown in Eq. (7). Combining Eqs. (6) and (7) and the values in Table 2, the enthalpy of mixing ΔHmix for the HfNbTaTiZr high-entropy alloy is calculated to be 2.72 kJ/mol. based on the above results and Eq. (3), the solid solution formation capacity parameter, Ω, is calculated to be 12.38. it has been shown that the criteria for the formation of a solid solution phase for a high-entropy alloy are δ ≤ 6.6% and Ω ≥ 1.1 [45]. Therefore HfNbTaTiZr high entropy alloy can form solid solution.

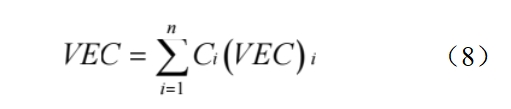

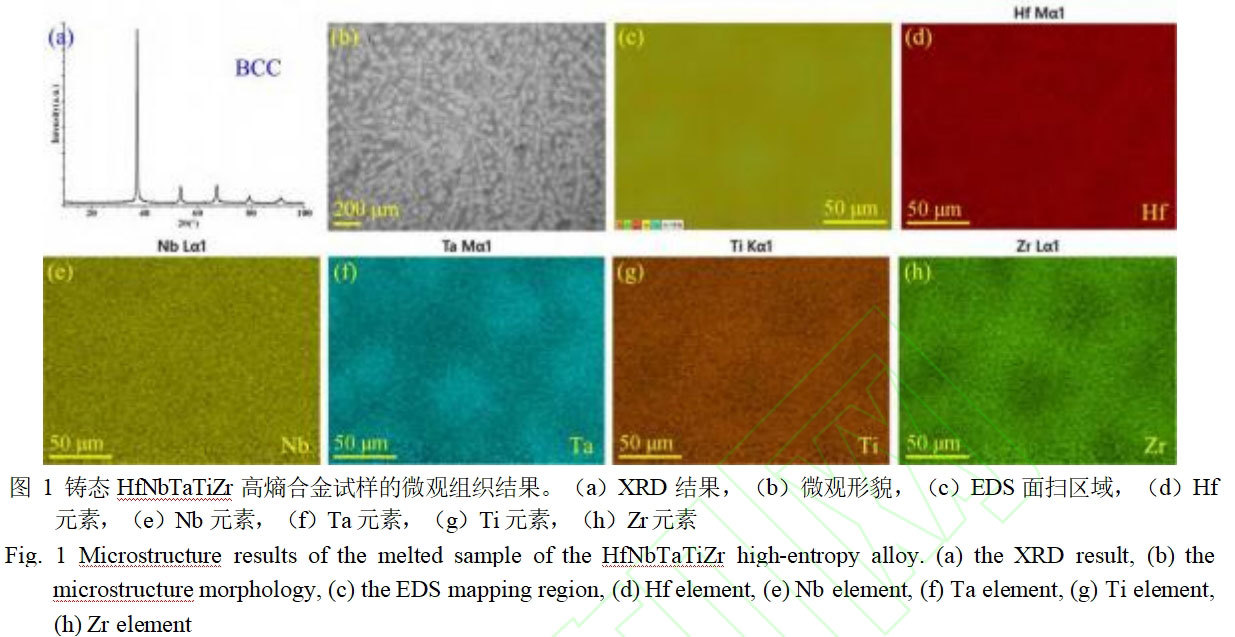

Combined with the valence electron concentration VEC (ValenceElectronConcentration), it can be judged that the crystal structure of the solid solution formed by high-entropy alloys is FaceCenteredCubic (FCC), BodyCenteredCubic (BCC) or other structures: when the VEC<6.9, the solid solution is BCC phase; when the VEC > 8, the solid solution is FCC phase; when 6.9 < VEC < 8, the solid solution is a mixture of FCC and BCC [48]. Combining the valence electron concentrations of the constituent elements of the high-entropy alloy (Table 1) and Eq. (8) yields that the VEC of the HfNbTaTiZr high-entropy alloy is 4.4, and therefore the solid solution formed in this high-entropy alloy is a BCC structure.

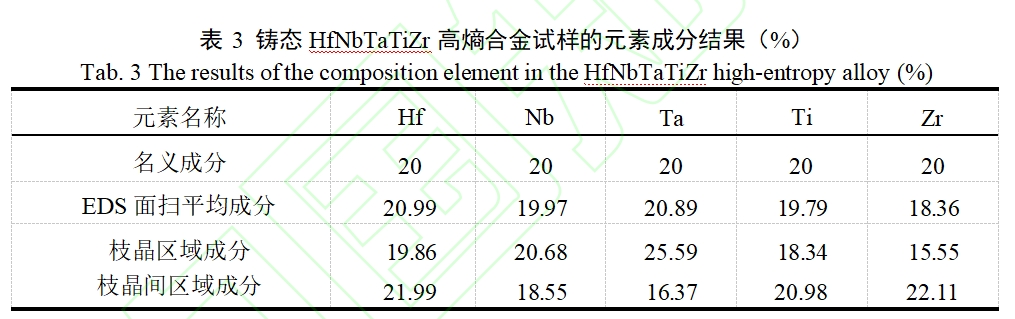

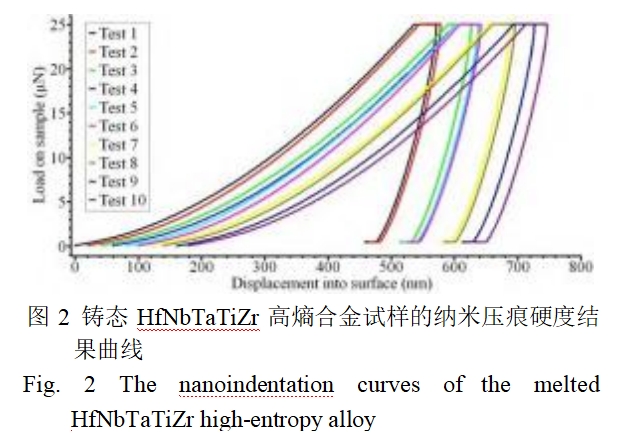

HfNbTaTiZr high-entropy alloy as-cast raw specimens are shown in Fig. 1.The results of XRD show that the high-entropy alloy is BCC structure (Fig. 1(a)), which is in line with the parameter calculations and analytical results above.The SEM results show that its microstructure is a typical as-cast dendritic organization, as shown in Fig. 1(b).The results of the EDS surface scanning results (Figs. 1(c)~1(h)) show that Ta and Zr are enriched to some extent in the dendritic and interdendritic regions, respectively. The nominal compositions of the constituent elements of the alloys, the average compositions determined by EDS surface scanning, and the results of the compositions of the elements in the dendrites and interdendrites are shown in Table 3. The actual composition of the alloy (average composition determined by EDS surface scanning) does not differ much from the nominal composition, with Nb slightly enriched in the dendritic region and Hf and Ti slightly higher in the interdendritic region. The Vickers hardness tester measurements of the as-cast specimens of the alloy were 303.58, 305.16 and 312.24 HV5, which gave a hardness of 306.99 ± 4.61 HV5 (mean ± standard deviation). Ten nanoindentation tests were carried out on the surface of the cast specimens and their nanoindentation hardness was 5.167 ± 0.23 GPa as shown in Table 4 and Figure 2.

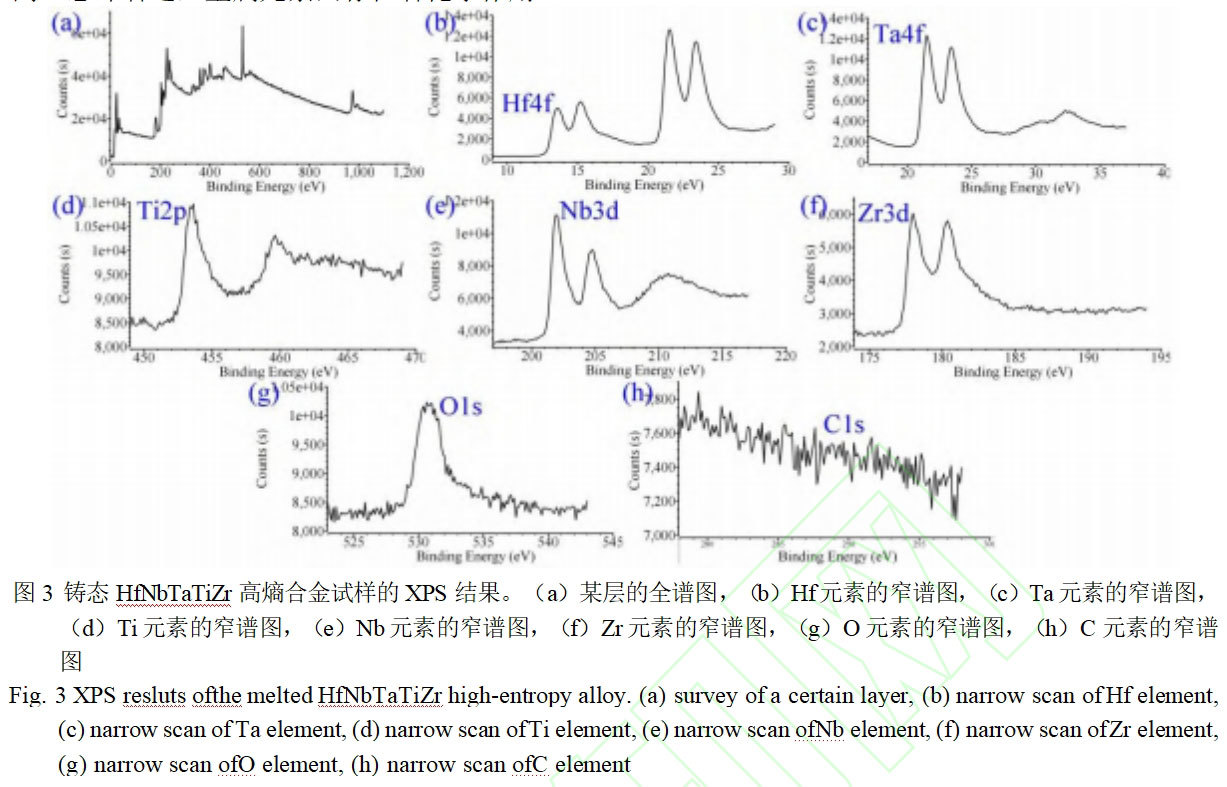

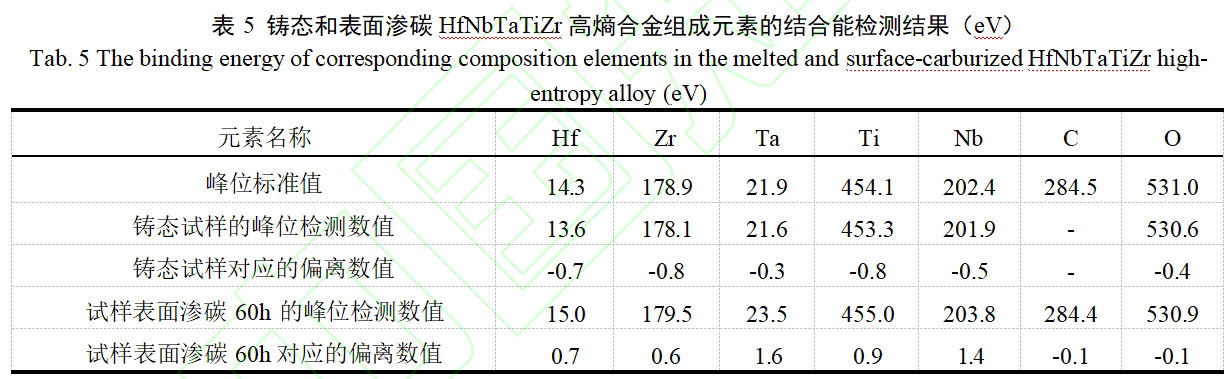

The XPS results of the surface of the cast HfNbTaTiZr refractory high entropy alloy specimens are shown in Fig. 3 and Table 5.The XPS full spectrum (Fig. 3(a)) and the narrow spectrum (Fig. 3(b)~3(h)) show characteristic peaks of the binding energies for the elements of Hf, Nb, Ta, Ti, Zr, and O, however, it does not contain that of the element C. The element O is supposed to be introduced by the raw materials of the metal element powder by the The presence of O shifts the binding energy peaks of the corresponding metal elements in the high-energy direction. However, the binding energy peaks of the five metal elements are still shifted in the low-energy direction, although this low-energy shift must have been partially offset by the presence of O. This indicates that the high-entropy alloys are characterized by the presence of O. This indicates an elevated average electron density around the constituent elements of the high-entropy alloy, implying that there is a chemical interaction between these metal elements.

2.2 Effect of surface carburization on alloy specimens

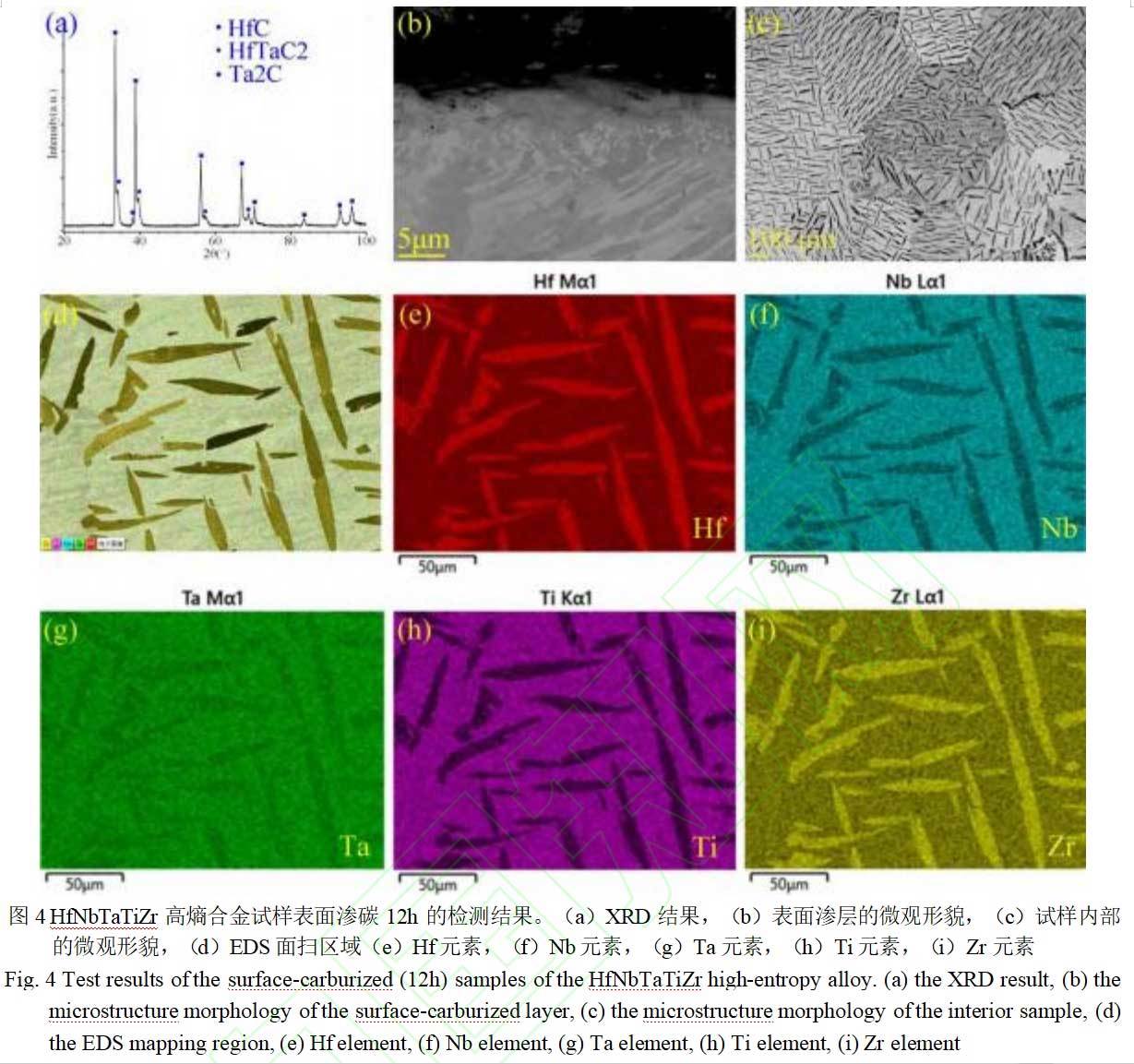

The surface carburization of HfNbTaTiZr refractory high entropy alloy specimens was carried out at a temperature of 1500°C, a treatment time of 12h, a load penetration ratio of 20, and a furnace pressure of 50 Pa. The results of the microstructure and elemental compositions of HfNbTaTiZr refractory high entropy alloy specimens were examined and are shown in Fig. 4 and Table 6. The XRD results (Fig. 4(a)) show that the surface phases are HfC, HfTaC2 and TaC2, where the content of HfC is the most and the content of TaC2 is very little. SEM was used to observe the morphology and thickness of the surface layer (some results are shown in Fig. 4(b)), and it was concluded that the thickness distribution was in the range of 2.5-6 μm.The precipitation phases in the matrix inside the specimen were generally in the form of laths and stripes, which were roughly arranged in parallel, perpendicular, or at an angle of about 50° in the same grain, as shown in Fig. 4(c). This implies that the precipitated phases have a specific crystallographic orientation with respect to the matrix. The precipitated phase consists mainly of the elements Hf and Zr, while the content of the elements Nb, Ta and Ti is very low; the matrix exists an enrichment of the elements Nb, Ta and Ti, while the content of the elements Hf and Zr is almost reduced by half, as shown in Table 6.

The test results of the surface hardness of the alloy after surface carburizing for 12h are 2122.18, 2035.82 and 2006.81 HV5, respectively, and its hardness is 2054.94±60.01 HV5, which is about 6.7 times of that of the as-cast specimen. This means that surface carburizing can significantly improve the hardness and wear resistance of HfNbTaTiZr refractory high-entropy alloy.

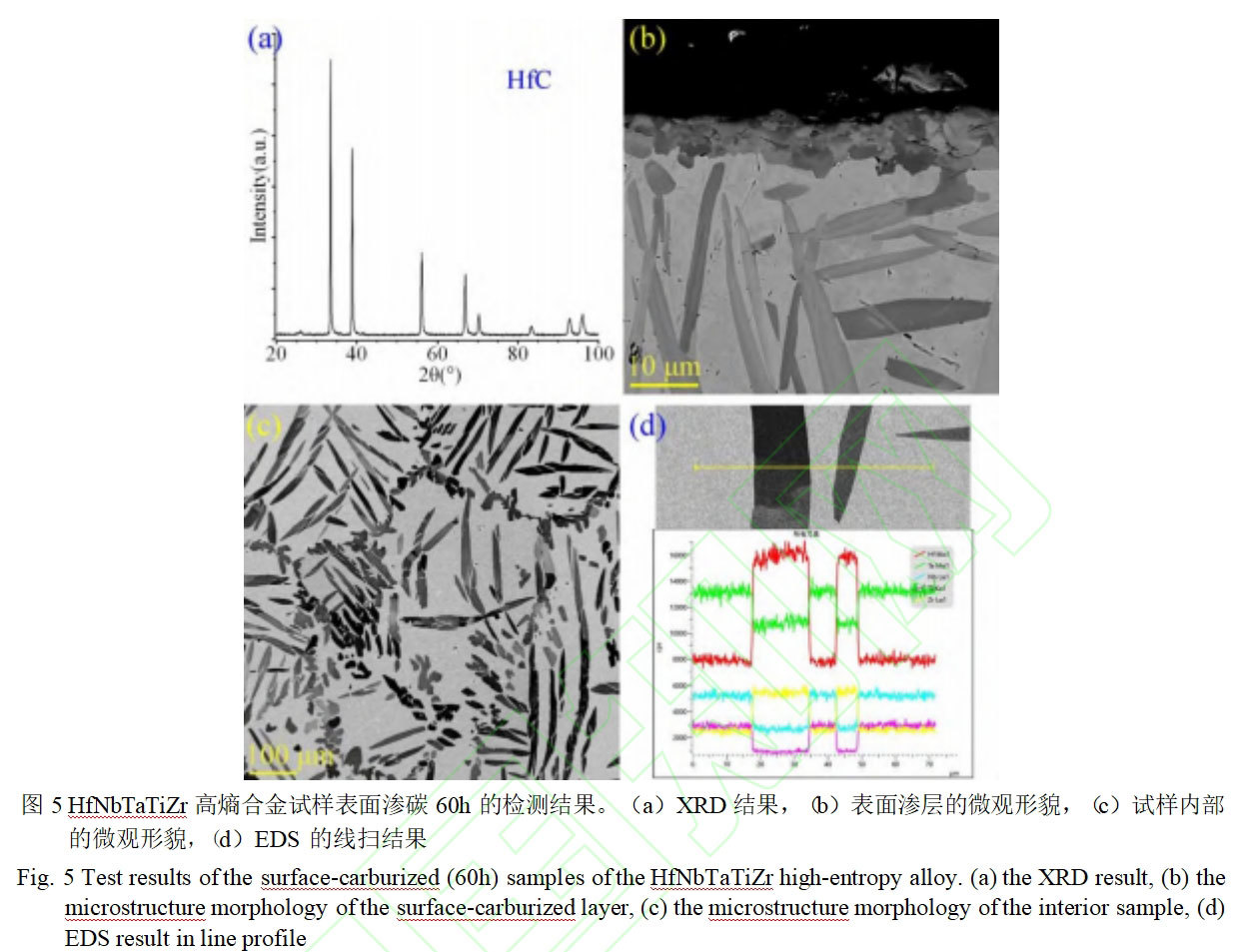

The microstructure examination results of HfNbTaTiZr refractory high entropy alloy when the surface carburization treatment time is 60 h are shown in Fig. 5. The XRD results show that the surface physical phase is HfC, as shown in Fig. 5(a). SEM was used to observe the morphology and thickness of the surface infiltration layer (part of the results are shown in Fig. 5(b)), resulting in a thickness distribution in the range of 4-9.5 μm. The presence of slate or patchy precipitation phases was prevalent inside the specimen, and the regularity of the arrangement of the precipitation phases was reduced in comparison with that of the alloy specimen with a surface carburized for 12 h, as shown in Fig. 5(c). The EDS line-scan results showed that the elements of Hf and Zr were enriched in the region of precipitation phases, while Ta, N, and TiZr elements were concentrated in the area of Hf, N and TiZr. enriched while Ta, Nb and Ti elements are enriched in the matrix region as shown in Fig. 5(d) and Table 6. The elemental compositions of the internal precipitation phase and the matrix are basically the same after 12h and 60h of surface carburizing of the alloy specimens.

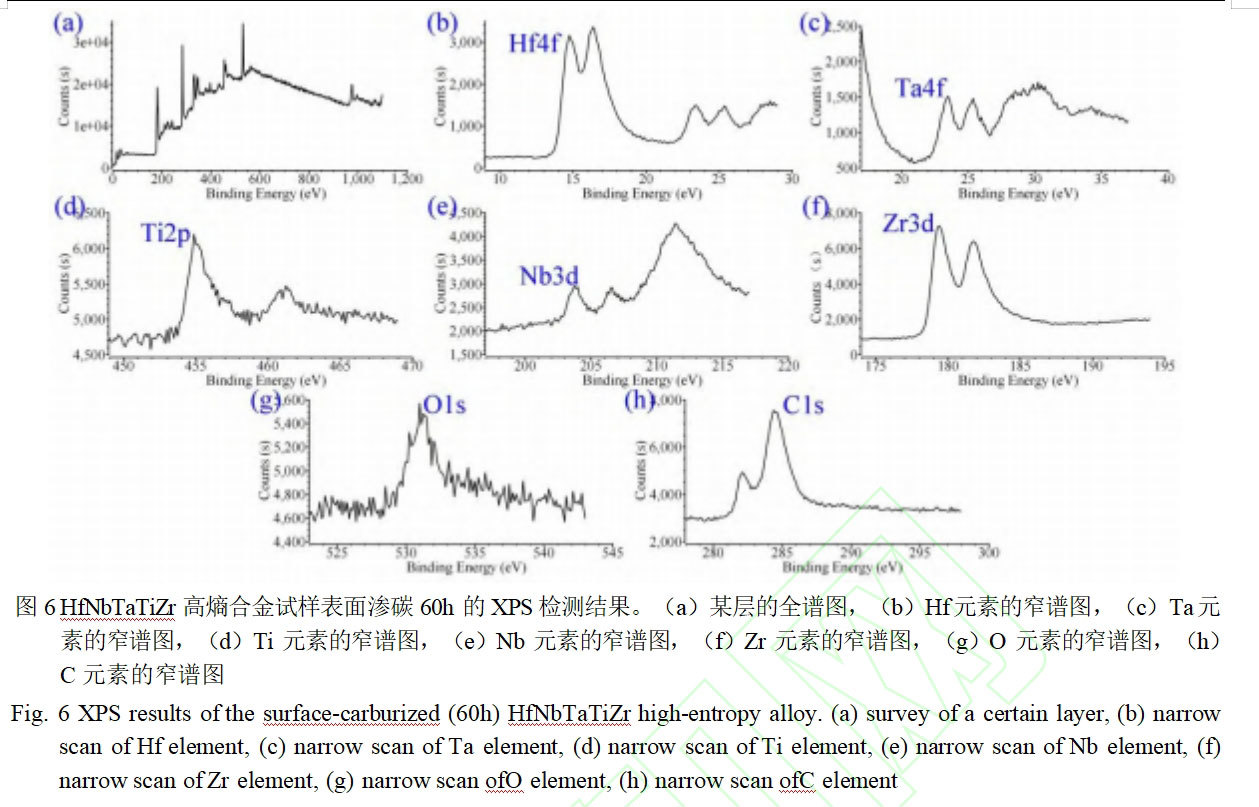

The XPS results of the specimen surface after 60h of surface carburizing treatment are shown in Fig. 6. The XPS full spectrum (Fig. 6(a)) and narrow spectrum (Figs. 6(b)~6(h)) show the characteristic peaks of the binding energies of the elements Hf, Nb, Ta, Ti, Zr, O, and C. The binding energies of these elements are shown in Fig. 5(a) and Table 6. The binding energy characteristic peak positions of these five metal elements are significantly shifted to the high energy direction (Table 5). Compared with the sufficient amount of C introduced by surface carburizing treatment, the trace amount of O does not significantly affect the shifting results of the binding energy characteristic peak positions of these metal elements. In other words, despite the fact that the surface phase shows HfC, the chemical process of electron gain and loss exists for both C elements and these metal elements.

2.3 Effect of high-temperature rolling on alloy specimens

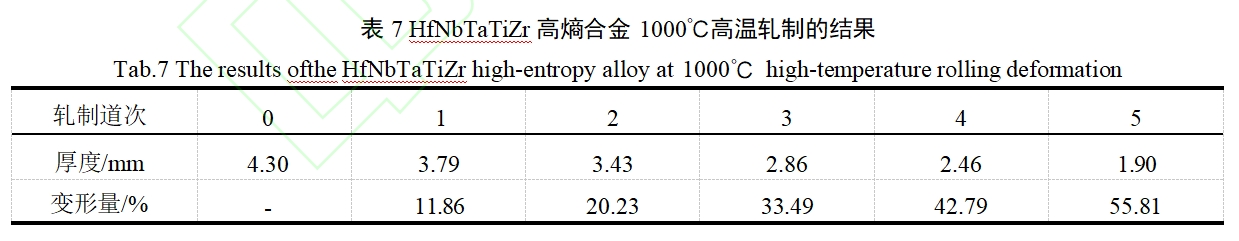

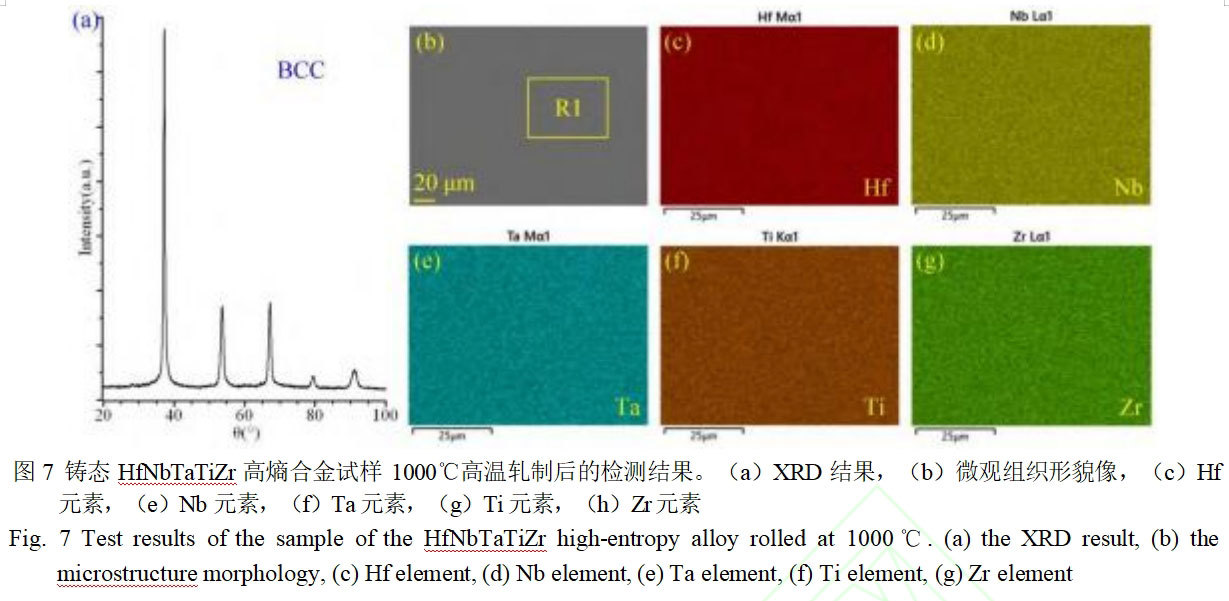

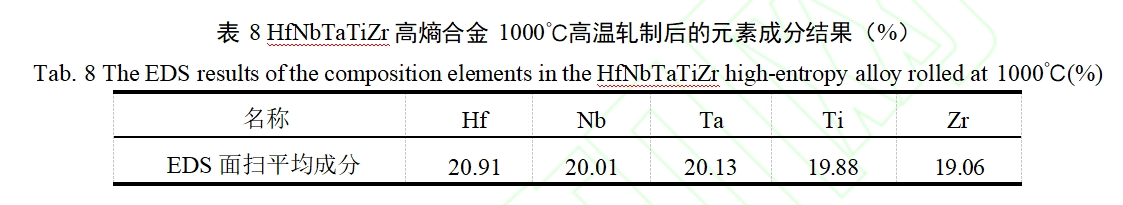

The calculated results of the deformation of HfNbTaTiZr high-entropy alloy before and after high-temperature rolling at 1000°C are shown in Table 7. The initial rolling thickness of the alloy is 4.30 mm, the final rolling thickness is 1.90 mm, the total deformation of rolling is 55.81%, and there is no macroscopic crack on the surface of the alloy after 5 passes of rolling.XRD results show that the specimen is a single-phase BCC structure, as shown in Fig. 7(a). The internal microstructure of the alloy was dense and no defects such as cracks or holes were observed, as shown in Fig. 7(b). It was shown that the room temperature compression plasticity of the alloy was more than 50% [26]. This implies that the HfNbTaTiZr high-entropy alloy has good room temperature and high temperature mechanical properties. EDS surface scanning was performed on the R1 region of Fig. 7(b), and the results, as shown in Figs. 7(c) to 7(g) and Table 8, do not observe any enrichment of the constituent elements of the high-entropy alloy in the localized region. This implies that the high-temperature rolling process at 1000°C can homogenize the microstructure of the alloy cast specimens.

3 Conclusions

In this paper, the effects of surface carburizing and high-temperature rolling on the microstructure and hardness of HfNbTaTiZr refractory high-entropy alloys have been investigated mainly by using low-pressure vacuum surface carburizing, XRD, SEM, and nanoindentation techniques. The as-cast HfNbTaTiZr refractory high-entropy alloy is a single-phase BCC structure. The characteristic peak positions of the binding energies of the five constituent elements of the as-cast high-entropy alloy are shifted to the low-energy direction, indicating that the average electron density around these metal elements is increased, implying the existence of chemical interactions between the atoms of different kinds of metals. The carburized layer can be prepared on the surface of the high-entropy alloy at a temperature of 1500℃, a treatment time of 12h, a carrier-carburization ratio of 20, and a furnace pressure of 50 Pa. The carburized layer is composed of HfC, HfC, HfC and HfC. The physical phases of the carburized layer are HfC, HfTaC2 and TaC2, and the thickness distribution of the carburized layer is in the range of 2.5-6 μm. When the treatment time is extended to 60 h, the physical phase of the carburized layer is HfC, and the thickness distribution of the carburized layer is in the range of 4-9.5 μm, and the XPS results show that there are chemical interactions between these metal elements and carbon elements. The hardness of HfNbTaTiZr refractory high-entropy alloy can be significantly improved by surface carburizing treatment. After the surface carburizing treatment, there are regularly arranged lath-like precipitation phases inside the specimens, whose main components are Hf and Zr elements, and these precipitation phases have a specific crystallographic orientation relationship with the matrix. When the carburizing treatment time is extended, the chemical composition of the precipitated phases remains basically unchanged while their shapes may change. In addition, the elements Ta, Nb and Ti are mainly enriched in the matrix. The total deformation of the alloy can reach 55.81% during high temperature rolling at 1000°C, and its microstructure is dense and crack-free.

References: HfNbTaTiZr refractory high entropy alloy surface carburization and high temperature rolling study

Yang Guang1,2,* Li Jinna3 Pang Yun3 Ma Xian1,2 Wang Ding Ding1 Ma Shangyi4 Liu Jiwen3

(1. Nuclear Industry Physical and Chemical Engineering Research Institute, Tianjin 300180, China;

2. National Key Laboratory of Particle Transport and Enrichment Technology, Tianjin 300180, China;

3. School of Materials Science and Engineering, Northeastern University, Shenyang 110819, China;

4. Institute of Metals, Chinese Academy of Sciences Shenyang 110016)

The spherical HfNbTaTiZr refractory high-entropy alloy powder provided by Stardust Technology Corporation has excellent high-temperature stability, corrosion resistance and mechanical properties, and is suitable for high-temperature components and protective coatings in aerospace and nuclear industries. The alloy powder enhances print molding performance and densification through uniform element distribution and spherical morphology. The powders prepared by Stardust Technology with advanced atomization technology have good fluidity and low oxygen content, which can meet the demands of additive manufacturing and thermal spraying processes and provide customers with high-performance material solutions. For metal powder needs, welcome to contact our professional and technical staff, Manager Zheng +86 13318326187.