Effect of rhenium content on the friction and wear properties of tungsten rhenium alloys

Release time:

2025-06-23

Tungsten (W) is widely used as a stirring head material for stir friction welding of high melting point alloys such as stainless steel, titanium and titanium alloys, by virtue of its good high temperature strength, high thermal conductivity and excellent wear resistance [1-2]. Although pure tungsten material has excellent high temperature strength, however, it has limitations in its application range. These limitations make pure tungsten easy to wear out in the service process, and cannot meet the requirements of “long life and high reliability” of stirring head materials for friction welding process. In order to break through this technical bottleneck, researchers have added trace elements to tungsten to improve its comprehensive performance, of which the addition of rhenium (Re) has a significant effect. Geach and Hughes [3] found that the alloying of Re can effectively solve the problem of brittleness of W, which is known as the “rhenium effect”. This effect not only significantly enhanced the stability of the grain structure of tungsten alloys, and increased its recrystallization temperature, but also successfully reduced its plastic-brittle transition temperature, thus greatly improving the tungsten alloy machinability at room temperature. In particular, tungsten rhenium alloys with high rhenium content show lower tough-brittle transition temperatures, higher ductility, and more excellent machinability [4-6].

In order to further optimize the performance of tungsten rhenium alloys, researchers hope to optimize the powder metallurgy process to prepare high density tungsten rhenium alloys with high rhenium content, aiming to improve its processability and broaden the conditions of use [7-10].Fukuda et al. [11] showed that rhenium additions can significantly refine the grain size of tungsten rhenium alloys, and improve their hardness. As the content of Re increases, the grain size of the alloy becomes finer, and its hardness increases significantly [5]. This grain refinement effect is essential to improve the wear resistance and high temperature strength of the alloy, so that tungsten rhenium alloy as a stirring head material shows more excellent friction stir welding performance. Therefore, tungsten rhenium alloy has gradually become the preferred stir head material for friction stir welding of high melting point alloys such as titanium alloy [12], stainless steel [13] and refractory metals [14]. Although the application of tungsten rhenium alloy in the field of friction stir welding has made significant progress, but not many research reports on its friction and wear properties, especially for different rhenium content of tungsten rhenium alloy friction and wear performance differences is rare. Therefore, the purpose of this paper is to explore the friction and wear properties of tungsten rhenium alloys with different rhenium contents, with a view to promoting the application and development of tungsten rhenium alloy stirring head materials in more high-end manufacturing fields.

1 Experiments

Two tungsten-rhenium alloys with different rhenium contents, W-7Re (mass fraction) and W-25Re (mass fraction), were prepared by powder metallurgy. The preparation process is as follows: firstly, tungsten powder with purity of 99.95% and Fischer's size of 3.5 μm and rhenium powder with purity of 99.99% and Fischer's size of 5 μm were proportionally weighed, and then they were ball-milled and mixed in argon atmosphere by using an omni-directional planetary ball mill. During the ball milling process, the rotational speed was controlled at 300 r/min, the ball to material ratio was 3:1, and the ball milling time was 8 h. Subsequently, the ball-milled alloy powder was loaded into a rubber sleeve under a pressure of 250 MPa, and the raw blanks were molded in a cold isostatic press. Next, the pressed billet was placed into a high-temperature sintering furnace for densification sintering at 2300°C. After that, the sintered tungsten rhenium alloy cooked billet was processed by spin forging machine with controlled deformation of 70%. Finally, the processed tungsten rhenium alloy was put into the annealing furnace and annealed at 1100℃×1h, followed by metallographic organization observation and performance testing.

Metallographic organization observation was carried out using OLYMPUS OLS5000 laser confocal scanning microscope; elemental distribution test was carried out using Aprohivac field emission scanning electron microscope; and friction and wear performance test was carried out using Rtec-Instruments (MFT-5000) friction and wear tester at room temperature and 1000°C, respectively. During the tests, Al2O3 was used as the friction vice, the load was set at 50 N, the circumferential diameter was 5 mm, and the rotational speed was 400 r/min. In addition, the UP-Lambda equipment was used to characterize the three-dimensional profile of the samples.

2 RESULTS AND DISCUSSION

2.1 Organizational structure

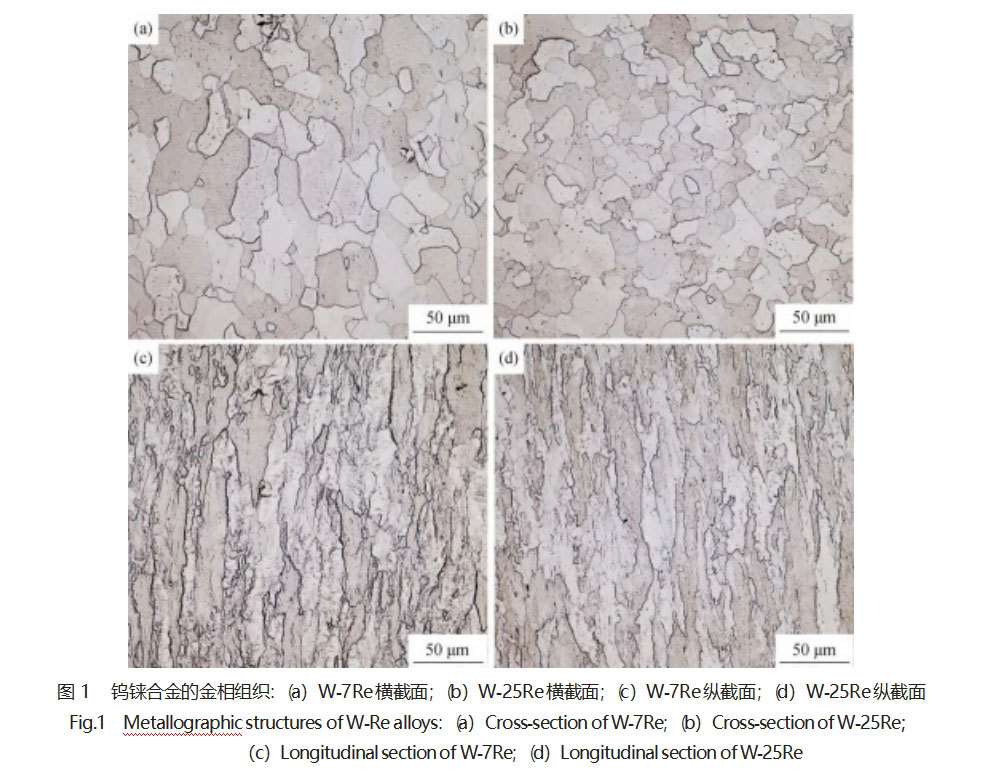

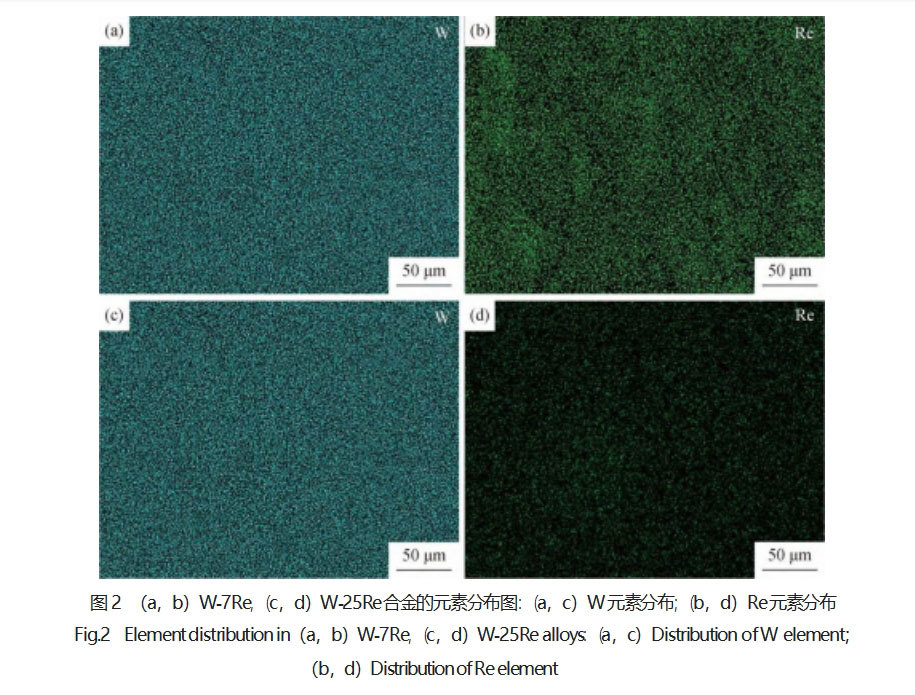

Fig. 1 demonstrates the transverse and longitudinal cross-section metallographic organization of W-7Re and W-25Re alloys. It is observed that the internal organization of tungsten rhenium alloys with different rhenium contents all show extremely high densities, and basically no holes can be observed. Compared with Figure 1 (a, b), it can be clearly seen that the grain size of W-25Re alloy is significantly smaller than that of W-7Re alloy, and this observation strongly proves that the Re element has the effect of refining the grain size of tungsten rhenium alloy, and the higher the content of Re, the more pronounced this refining effect. This phenomenon is highly consistent with the phenomenon observed in the preparation of tungsten rhenium alloys using hot press sintering and discharge plasma sintering methods [15]. By observing the elemental distribution diagrams in Figure 2, it can be clearly seen that in the two tungsten rhenium alloys with different rhenium contents, the Re element is uniformly distributed, with no obvious segregation-enriched areas, which indicates that the Re element is mainly solid-solved in the W matrix. Further comparison found that the distribution of Re elements in W-25Re alloy compared with W-7Re alloy appears to be more enriched and brighter, which further supports the higher content of Re in W-25Re alloy.The refining effect of Re on W grain is mainly attributed to the solid solution of Re will replace the position of W atoms in the lattice, and effectively inhibit the diffusion of W at high temperatures, which significantly slows down the growth process of W grains [16]. growth process [16]. Comparative analysis of Figure 1 (c, d), it can be found that the two rhenium content of tungsten rhenium alloy longitudinal cross-section grains are showing obvious fiber-like morphology, which is caused by the deformation of the material during the spin forging process. This fibrous grain structure has a positive effect on improving the strength and toughness of the alloy.

2.2 Friction and Wear Properties

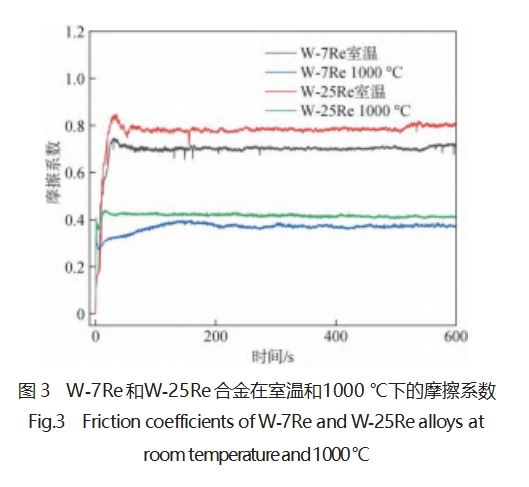

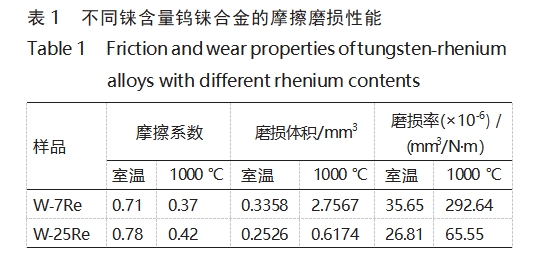

Fig. 3 shows the graphs of coefficient of friction versus time for W-7Re and W-25Re alloys at room temperature and 1000°C. It can be observed that the friction coefficient curves of all the tests show the same trend, i.e., a rapid rise followed by experiencing a certain degree of decline and eventually leveling off. At the initial stage of the friction test, due to the uneven surface of the friction vice and the smooth surface of the tungsten rhenium alloy specimen only point contact, resulting in a great load per unit area, which in turn produces a significant dry friction effect, resulting in a rapid increase in the coefficient of friction. As the friction test continues, the sliding friction between the friction pair and the specimen gradually increases, resulting in wear on the specimen surface, which makes the friction coefficient increase gradually. At the same time, the abrasive debris generated by the wear on the specimen surface adheres to the abrasion marks, which further causes the friction coefficient curve to fluctuate. However, with the gradual reduction of the adhering abrasive debris, the coefficient of friction of the specimen eventually stabilizes within a certain range, marking the friction test has entered the stable wear stage. In order to further quantify the analysis, the friction coefficients of the four samples in the friction stabilization stage were summarized in detail (see Table 1).The friction coefficients of W-7Re and W-25Re alloys at room temperature and 1000°C were 0.71, 0.78 and 0.37, 0.42, respectively.The comparative analysis shows that the friction coefficients of W-25Re alloy are higher than those of W-7Re alloy both at room temperature and 1000°C. 7Re alloy. It is noteworthy that the friction coefficients of the same samples at 1000°C are all significantly lower than those at room temperature. This phenomenon can be attributed to the softening phenomenon on the surface of tungsten rhenium alloys at high temperatures, resulting in a decrease in hardness. At the same time, the high temperature also promotes the oxidation reaction on the surface of the alloy, forming oxide skins. These oxidized skins play a lubricating role in the friction process, thus effectively reducing the coefficient of friction.

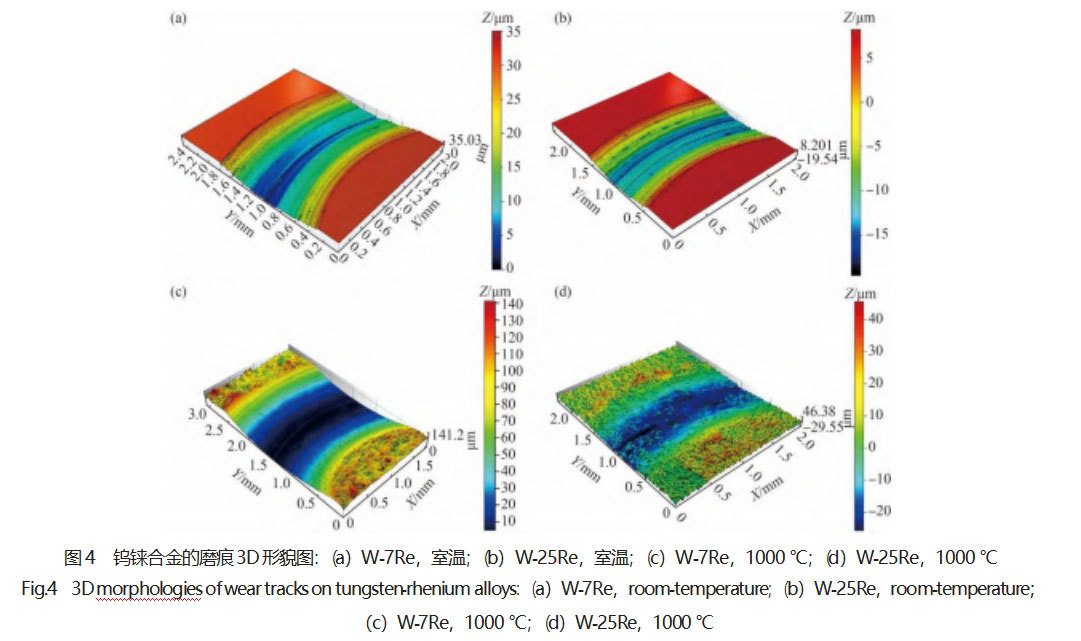

3D wear surface profiles of W-7Re and W-25Re alloys at room temperature and 1000°C high temperature are shown in Fig. 4. As can be seen from the figure, the wear scar profiles of tungsten rhenium alloys with different rhenium contents at room temperature all show continuous furrow characteristics, which may be formed by the abrasive wear caused by the solid particles present at the friction interface cutting and scraping the friction surface. Comparing the illustrations, it is clear that there is a large difference in the width and depth of the scratches between the W-7Re and W-25Re alloys. Specifically, the room-temperature abrasive scratches of W-25Re alloy are narrower and shallower compared to those of W-7Re alloy, which indicates that it possesses superior wear resistance. Observing Figure 4 (c, d), it can be found that the surface of the tungsten rhenium alloy specimens tested at a high temperature of 1000 ℃ is obviously rougher, and there is a significant difference between the abrasion marks at a high temperature of 1000 ℃ and at room temperature, and there are no obvious furrow marks on the abrasion tracks at high temperatures, which show a smoother pattern.

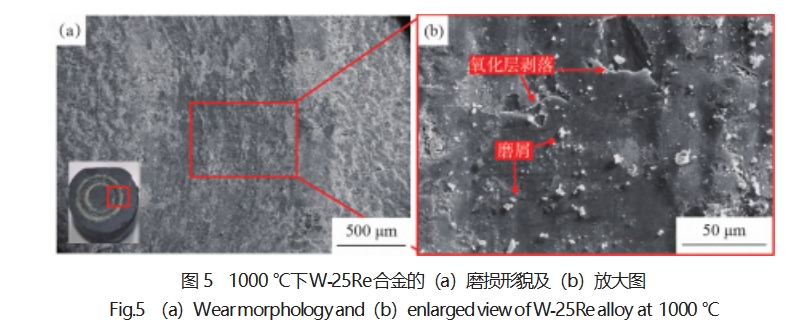

The wear morphology of W-25Re alloy at high temperature of 1000°C is further characterized and the results are shown in Fig. 5. It can be seen that there are obvious oxide layer flaking and enamel layer generation phenomenon on the surface of W-25Re, and the main characteristics of the wear morphology are oxide layer flaking and abrasive wear, while there is no obvious plough furrow morphology, which speculates that the wear mechanism is mainly oxidative wear and adhesive wear [17-18]. This may be the high temperature environment of 1000 ℃ exacerbated the oxidation process on the surface of tungsten rhenium alloy, resulting in the formation of loose oxide layer. These oxide layers are highly susceptible to flaking off during friction and are carried into the contact area by the friction vice, and eventually transformed into enamel layers under the action of squeezing force.

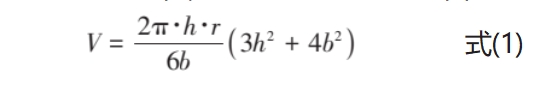

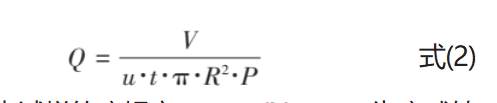

Wear volume and wear rate are important parameters for assessing wear resistance. Wear volume characterizes the size of the volume of the abraded material during the friction process, which is calculated as in equation (1), and wear rate is calculated as in equation (2).

where: v represents the wear volume of the specimen, mm3; h is the depth of the abrasion mark, μm; b is the width of the abrasion mark, mm; and r is the radius of the abrasion track, mm.

where: q represents the wear rate of the specimen, mm3/N-m; u is the rotational speed of the abrasive ball, r/min; t is the friction time, min; R is the radius of the abrasive ball, mm; and P is the load, N.

Based on the 3D abrasion surface profile in Fig. 4 of the depth and width information, the wear volume and wear rate of W-7Re and W-25Re alloys were calculated at room temperature and 1000°C high temperature (see Table 1), which shows that the wear volume and wear rate of tungsten rhenium alloys in high temperature environment are significantly higher than those in room temperature environment. This phenomenon can be attributed to the tungsten rhenium alloy at high temperatures are prone to produce oxidized skin layer, these oxidized skin layer not only increases the wear area, but also strengthen the wear process, resulting in an increase in the wear rate. At the same time, the hardness of tungsten rhenium alloys decreases at high temperatures, which makes the surface of the material more prone to plastic deformation and aggravates wear. By comparing the wear volume and wear amount of W-7Re and W-25Re alloys at room temperature and 1000°C high temperature environment, it is found that the wear volume and wear amount of W-25Re alloy are smaller. Combined with the friction coefficient results in Fig. 3, it can be concluded that the friction and wear performance of W-25Re alloy is significantly better than that of W-7Re alloy. This is because with the increase of rhenium content, the strength and hardness of tungsten rhenium alloys are significantly improved, making them more resistant to deformation and damage during frictional wear. In addition, the increase in rhenium content also makes the grain size of tungsten rhenium alloy finer, higher recrystallization temperature, which helps the alloy to maintain high strength at high temperatures. More importantly, high rhenium content of tungsten rhenium alloy has a stronger oxidation resistance, in the high temperature and frictional wear process is not easy to form an oxide layer, thus effectively slowing down the occurrence of oxidative wear [19-20].

3 Conclusion

(1) The rhenium content in tungsten rhenium alloy has a significant effect on its grain size, the higher the rhenium content, the finer the grain size of tungsten rhenium alloy.

(2) The friction and wear performance of tungsten rhenium alloy at high temperature is reduced compared with room temperature environment. In the high temperature environment, the wear mechanism is mainly dominated by oxidative wear and adhesive wear; in contrast, in room temperature conditions the wear mechanism is mainly manifested as abrasive wear.

(3) The wear resistance of tungsten rhenium alloys increases with the increase of rhenium content, and the wear resistance of W-25Re alloy is better than that of W-7Re alloy at both room and high temperatures.

Reference:Chinese Figure Classification Number: TG146.4+ 1 Literature Identification Number: A Article Number 1009-3842(2025)02-0063-06

Stardust Technology provides high-purity spherical tungsten rhenium alloy powders (W-5Re, W-15Re, W-25Re), which are prepared by RF plasma spheronization process, with excellent sphericity (>95%) and narrow particle size distribution. Product purity ≥99.95%, oxygen content <200ppm, excellent fluidity (Hall flow rate <15s/50g), especially suitable for aerospace engine components, nuclear industry, high temperature components and electronic packaging materials for 3D printing and powder metallurgy. The addition of rhenium significantly improves the ductility and recrystallization temperature of tungsten alloys, among which W-25Re still maintains high strength at 2000℃, making it an ideal choice for extreme environmental applications. We support customized particle size ratio and surface modification services. For metal powder inquiries, please feel free to contact us at Manager Zheng 13318326187.