Study on Mechanical Properties and Fracture Behavior of 93W-4.9Ni-2.1Fe Alloy

Release time:

2025-06-18

High-density tungsten alloy is an alloy with tungsten as the matrix (tungsten content is 85%~99%) and a small amount of Ni, Fe, Co, Cu, Mo, Cr, Mn and other elements added. Its density is as high as 16.5~19.0 g/cm3. It has a series of excellent properties such as high density, high strength, good toughness, good machining performance, good electrical and thermal conductivity, small thermal expansion coefficient, good corrosion resistance and oxidation resistance. Therefore, it has been widely used in modern scientific fields, national defense, aerospace and civil industries [1-3].

High-density tungsten alloy is a typical liquid phase sintered two-phase structural material. The microstructure is high-strength tungsten grains and high-ductility bonding phase. The mechanical properties of tungsten alloys are closely related to the tungsten grain size, the bonding between tungsten grains and between tungsten grains and the binder phase, the presence of pores and inclusions, the precipitation of intermetallic compounds, and other characteristics. These characteristics are related to the raw material powder, alloy composition, sintering process, and post-sintering heat treatment [4]. Domestic and foreign scholars have conducted a lot of research on high-density tungsten alloys. Studies have shown that sintering temperature has a significant effect on the structure and properties of high-density tungsten alloys. Wu Enxi [5] and others found that high-density tungsten alloys with different compositions can obtain the best performance at the appropriate sintering temperature of 1470~1510℃, and lower or higher temperatures will reduce their mechanical properties. L.L. Bourgujgnon [6] and others found that when the 93W-4.9Ni-2.1Fe alloy prepared from tungsten powder with a Fehler particle size of about 3 μm was sintered at 1465~1580℃, the strength decreased and the elongation increased with the increase of sintering temperature. Other scholars have found that alloys can only have higher strength and plasticity when sintered at higher temperatures [7]. The sintering atmosphere of high-density tungsten alloys generally uses hydrogen in order to fully remove impurity elements such as O and C in the alloy. However, the residual hydrogen will cause hydrogen embrittlement in the alloy. However, heat treatment in nitrogen atmosphere, argon atmosphere or vacuum after sintering can effectively eliminate hydrogen embrittlement and greatly improve the performance of the alloy [7-8]. Guan Mo [9], Li Xiaoqiang [10] and others also found that the contact between tungsten grains in high-density tungsten alloys will gradually decrease with the increase of heat treatment times. After cyclic heat treatment of 93W-Ni-Fe alloy, the hardness, bending strength, fracture deflection and other properties of the alloy are correspondingly improved. At present, there are few studies on the effect of raw tungsten powder particle size on the mechanical properties of high-density tungsten alloys. The experiment took 93W-4.9Ni-2.1Fe high-density tungsten alloy as the research object, systematically studied the influence of factors such as raw material tungsten powder particle size, sintering temperature, heat treatment process on the mechanical properties of high-density tungsten alloy, and conducted an in-depth analysis of its room temperature tensile fracture behavior.

1 Experimental part

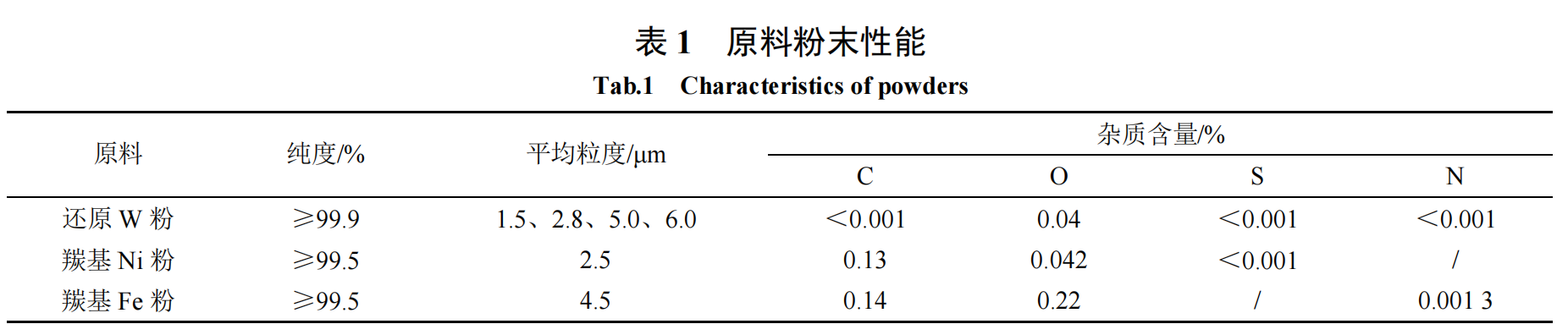

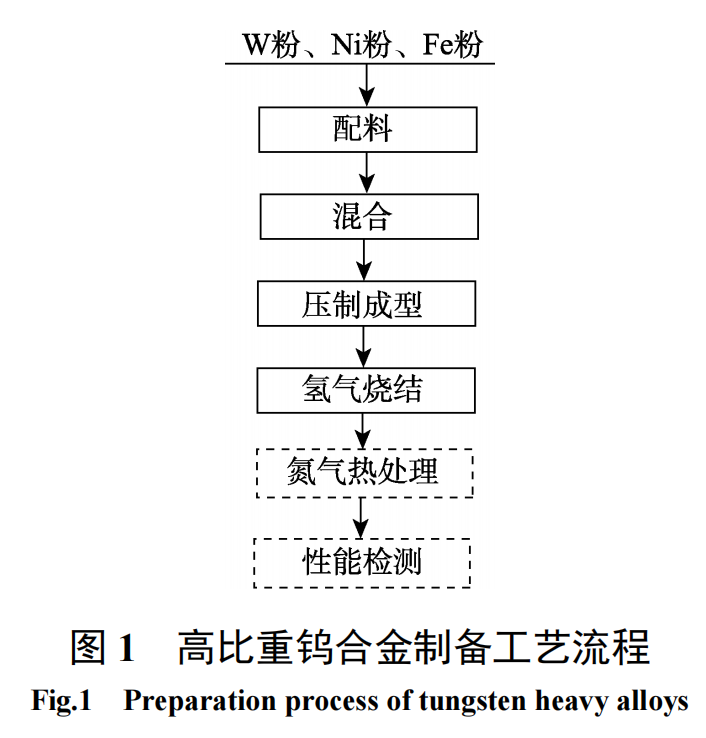

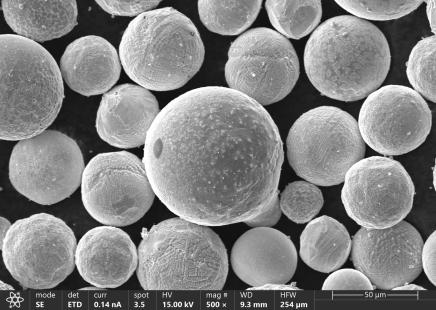

The experiment used reduced W powder, carbonyl Ni powder and carbonyl Fe powder of different particle sizes as raw materials. The raw material powder properties are shown in Table 1. The preparation process is shown in Figure 1: the raw material powder is mixed according to the mass ratio of W:Ni:Fe=93:4.9:2.1, mixed in a mixer for 16 hours and then pressed into a green compact with a diameter of 14 mm×200 mm and a pressing pressure of 4.0 MPa; then sintered in a sintering furnace with a hydrogen atmosphere, a sintering temperature of 1415~1550℃ and a sintering time of 2 hours; solid solution + quenching heat treatment is carried out in a nitrogen atmosphere with a heat treatment temperature of 1240±10℃ and a heat treatment time of 3.0 hours.

The density of tungsten alloy was determined according to GB/T 3850-2015 "Determination of density of dense sintered metal materials and cemented carbide", and the sintering density was the ratio of the sintering density of the sample to the theoretical density; the room temperature tensile test was determined according to GB/T 28.1-2010 "Metallic materials Tensile test Part 1: Room temperature test method", with a loading rate of 5 mm/min; the fracture morphology of the alloy was observed using a German Zeiss EVO618 scanning electron microscope.

2 Results and analysis

2.1 Effect of tungsten powder size and sintering temperature on sintering density

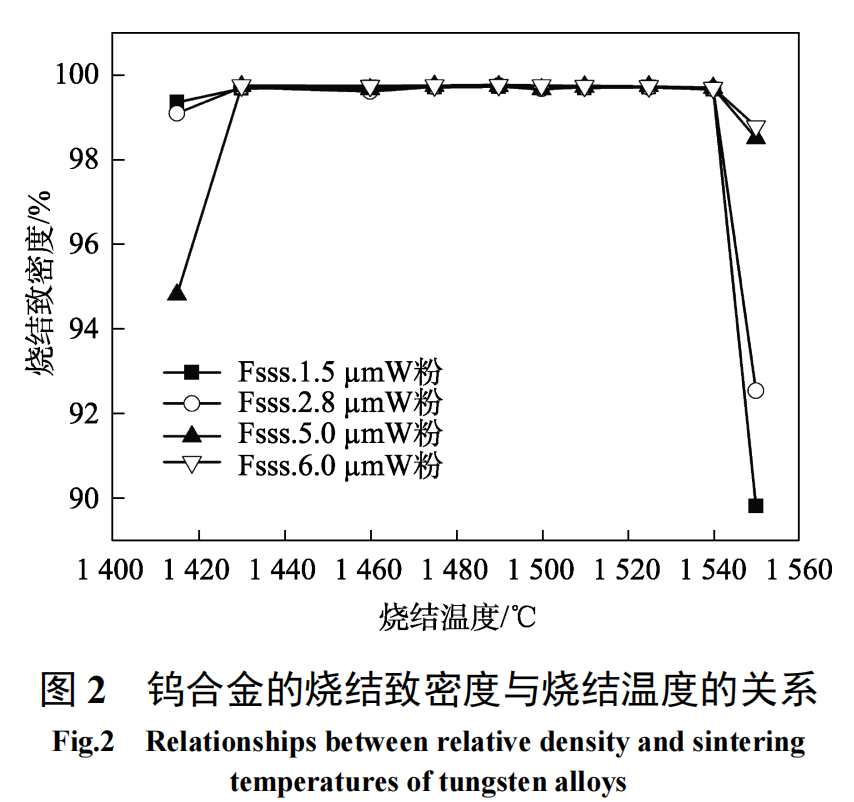

Figure 2 shows the relationship between the sintering density of 93W-4.9Ni-2.1Fe alloy prepared from raw tungsten powder of different particle sizes and sintering temperature. As can be seen from Figure 2, when the sintering temperature is 1415℃, the tungsten alloys prepared from the four tungsten powders are not dense, and the sintering density decreases with the increase of the tungsten powder particle size. Among them, the tungsten alloy prepared from the 6.0 μm tungsten powder has a slight water absorption phenomenon. This is because the finer the original particles of the raw tungsten powder, the higher its surface energy and the greater its sintering activity[11]. Therefore, when sintering at a lower temperature, the tungsten alloy is not completely dense. At this time, the sintering activity of the fine tungsten powder raw material is greater than that of the coarse tungsten powder raw material, and the sintering density of the tungsten alloy prepared is also higher. When the sintering temperature is 1430~1540℃, the tungsten alloys prepared from the four tungsten powders are basically fully dense, and the sintering density is ≥99.6%. When the sintering temperature is increased to 1550℃, the sintering density of the tungsten alloys prepared from the four tungsten powders begins to decrease, and the smaller the particle size of the raw tungsten powder, the lower the sintering density. This is because when high-density tungsten alloy is sintered at too high a temperature, the liquid phase formed in the alloy evaporates to form bubbles, which remain in the alloy after cooling, resulting in pores and a decrease in density. The finer the particle size of the raw tungsten powder, the greater the sintering activity, the more bubbles are formed, and the lower the density. BAEK W H believes that when the sintering temperature is too high, a large amount of liquid phase will trap the sintering gas in the pores and prevent them from closing, thereby inhibiting the densification of the alloy [12].

2.2 Effect of tungsten powder particle size and sintering temperature on mechanical properties

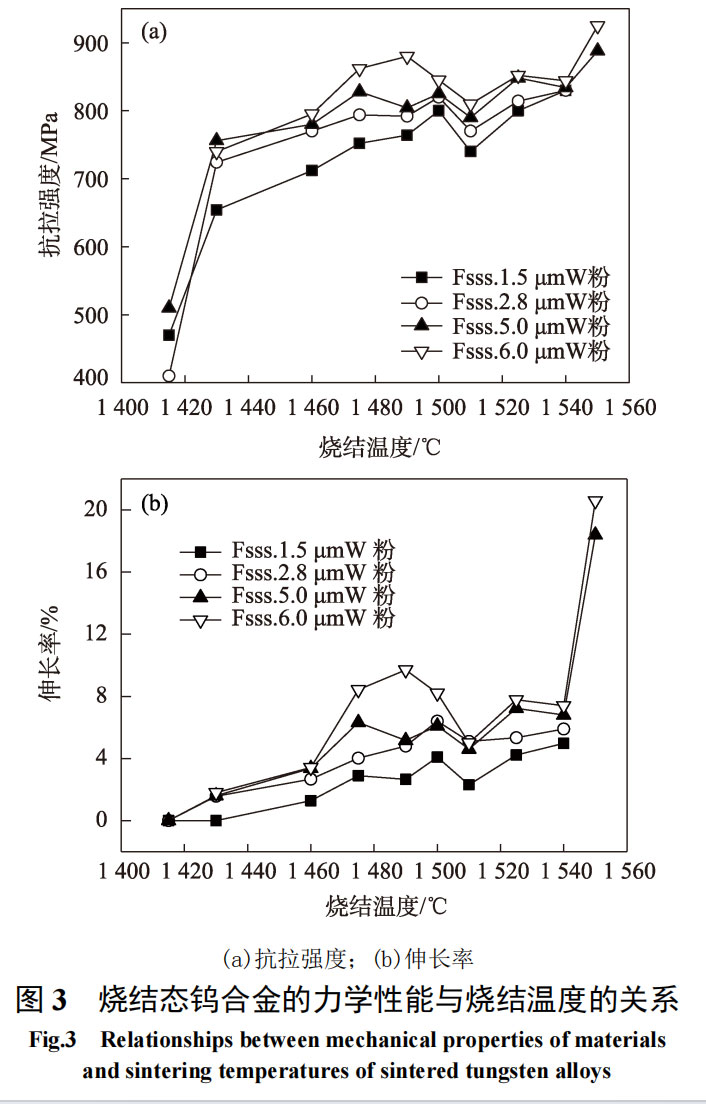

Figure 3 shows the relationship between the mechanical properties of the sintered 93W-4.9Ni-2.1Fe alloy prepared from raw tungsten powder of different particle sizes and the sintering temperature. As shown in Figure 3, when sintered in the temperature range of 1 415-1 550 ℃, the change rules of the tensile strength and elongation of the 93W-4.9Ni-2.1Fe alloy prepared by the four kinds of tungsten powder with sintering temperature are basically the same, which can be divided into three stages: when the sintering temperature is 1 415 ℃, the tensile strength and elongation of the tungsten alloy are very low, showing obvious brittleness, and then with the increase of sintering temperature, the tensile strength and elongation of the tungsten alloy gradually increase. When the sintering temperature is 1 500-1 510 ℃, the mechanical properties of the tungsten alloy decrease significantly. When the sintering temperature is further increased to about 1 525 ℃, the mechanical properties of the tungsten alloy begin to increase gradually, among which the tensile properties of the tungsten alloy prepared by 5.0 μm and 6.0 μm coarse tungsten powder are significantly improved when sintered at about 1 550 ℃. This is because the sintering mechanism of 93W-4.9Ni-2.1Fe alloy is a typical liquid phase sintering. When the alloy compact is heated to a certain temperature, the low melting point components Ni and Fe in the alloy form a liquid phase. On the one hand, the capillary force formed by the pores between the tungsten particles and the viscous flow of the liquid phase itself make the liquid phase fill the gaps between the tungsten particles; on the other hand, small tungsten particles and the edges and protrusions on the surface of the tungsten particles are preferentially dissolved in the liquid phase. When the tungsten dissolved in the liquid phase reaches the saturated solubility, it will precipitate on the surface of the large tungsten particles with lower surface energy [4,13]. As the sintering temperature increases, the liquid phase formed in the alloy flows fully under the action of capillary force, so that it is more evenly distributed between the tungsten particles, and promotes the dissolution and precipitation of tungsten in the liquid phase, so that a stronger metallurgical bond is formed between the tungsten grains and the bonding phase, which is beneficial to improving the mechanical properties of the alloy. The reason why the mechanical properties of tungsten alloys prepared from tungsten powders of different particle sizes decreased when sintered in the temperature range of about 1500-1510 ℃ is related to the isothermal transformation of nickel and tungsten near this temperature, which affected the sintering process [14].

In addition, when other conditions are the same, the mechanical properties of tungsten alloys prepared from coarse tungsten powder raw materials are generally higher than those of tungsten alloys prepared from fine tungsten powder raw materials at the same sintering temperature. This is because when the sintering temperature is low, the sintering activity of tungsten alloys is low, and the mechanical properties of the alloy are mainly related to the uniformity of the distribution of the bonding phase. The coarse tungsten powder raw materials have less powder agglomeration than fine tungsten powder, which is more conducive to the flow of the sintering liquid phase. When the sintering temperature is high, the activation energy of the coarse tungsten powder has been significantly improved, and it can quickly dissolve and precipitate in the liquid phase. In addition, the viscosity of the liquid phase is low at high temperature, which is also conducive to the dissolution and precipitation of coarse tungsten particles, so that the coarse tungsten particles grow to obtain coarser tungsten particles, and finally exceed the tungsten particle size prepared by fine tungsten powder at the same sintering temperature [13]. As the tungsten particles grow, the specific surface area decreases, and the bonding phase becomes thicker, the strength of the bonding phase is improved, and thus it has higher mechanical properties.

2.3 Analysis of tensile fracture morphology

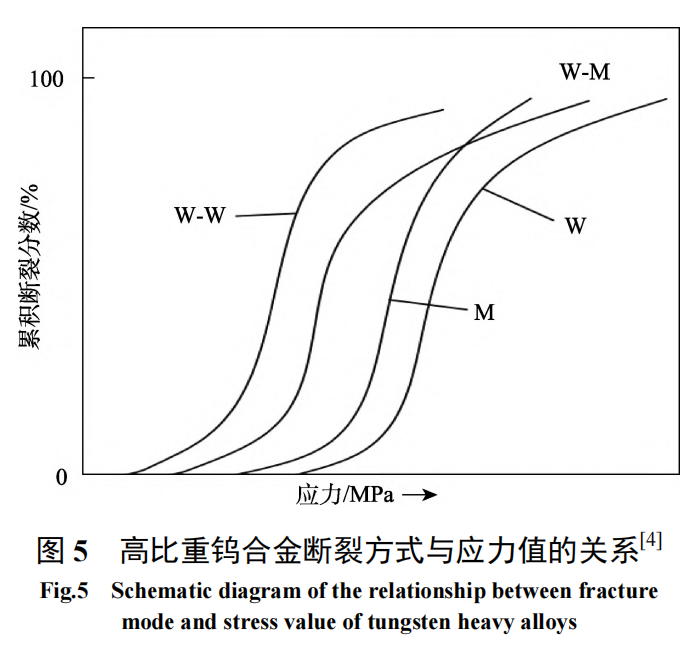

High-density tungsten alloy is a two-phase structure composed of high-strength tungsten grains and high-ductility bonding phase. There are four fracture modes [15-16], namely cleavage fracture of tungsten grains (W), bonding phase fracture (M), interface separation of tungsten-tungsten grains (W-W), and interface separation of tungsten grains-bonding phase (W-M). The fracture morphology is determined by the relative strength of the four fracture modes.

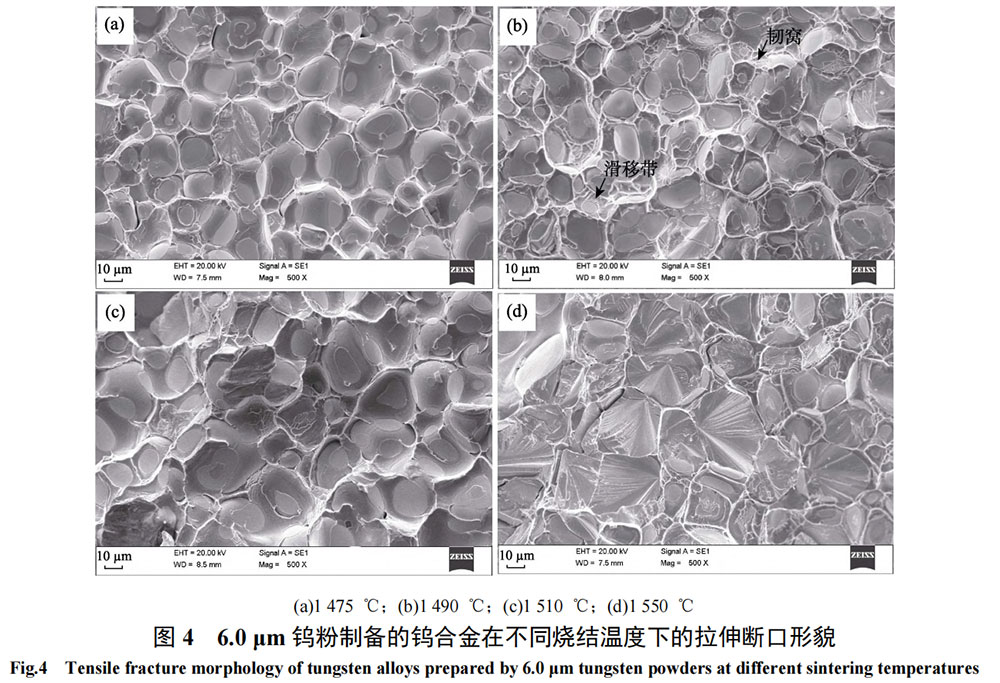

Figure 4 shows the tensile fracture morphology of 93W-4.9Ni-2.1Fe alloy prepared from 6.0 μm tungsten powder after sintering at different temperatures. As can be seen from Figure 4, the tensile fracture morphology of tungsten alloy sintered at 1475℃ is mainly the interface separation of tungsten-tungsten grains and tungsten grains-bonding phase, as well as a small amount of tungsten grain cleavage fracture. When the sintering temperature is 1490℃, it shows obvious tungsten-tungsten grain interface fracture and ductile fracture of the bonding phase, indicating that the interface bonding strength of tungsten grains-bonding phase increases with the increase of sintering temperature. When the applied tensile stress increases, the tungsten-tungsten grain interface is first destroyed, and the bonding phase hinders the expansion of cracks. With the increase of load, the bonding phase undergoes plastic deformation to produce slip bands or dimples, so the alloy has higher tensile strength and elongation at this time. When the sintering temperature reaches 1510℃, the ductile fracture of the bonding phase is significantly reduced, while the interface fracture of tungsten grains-bonding phase is increased. This is related to the isothermal transformation reaction of nickel and tungsten near the sintering temperature, which affects the dissolution and precipitation process of tungsten in the bonding liquid phase, resulting in a decrease in the interfacial bonding strength between tungsten grains and bonding phase. When the sintering temperature is 1550℃, the fracture morphology of tungsten alloy shows a high degree of tungsten grain transgranular cleavage fracture, ductile fracture of bonding phase and a small amount of tungsten-tungsten grain interface fracture. Since the stress value of tungsten grain transgranular cleavage fracture is much greater than the fracture stress value of bonding phase, tungsten-tungsten grain interface, and tungsten grain-bonding phase interface, the presence of a certain proportion of tungsten grain cleavage fracture will increase the macroscopic fracture resistance, thereby improving the tensile strength of tungsten alloy. At the same time, the presence of a large number of ductile dimples in the bonding phase on the fracture indicates that the bonding phase has undergone obvious ductile fracture. At this time, the tungsten alloy has higher tensile strength and elongation.

Figure 5 is a schematic diagram of the relationship between the four fracture modes and stress values of high-density tungsten alloys. As can be seen from Figure 5, the interface between tungsten grains is the weakest link in high-density tungsten alloys. During the tensile test, cracks preferentially initiate at the tungsten-tungsten grain interface. The bonding phase plays an important role in preventing the expansion of interface cracks. When the stress is high enough, the bonding phase will undergo plastic deformation. When the applied load continues to increase, the tungsten grains will eventually deform and transgranular cleavage fracture will occur. Therefore, the interface bonding strength of tungsten grains and bonding phase is the key factor in determining the mechanical properties of high-density tungsten alloys. When the fracture mode of tungsten alloys is transgranular cleavage fracture of tungsten grains and ductile fracture of bonding phases, the strength and plasticity of the alloy are good [17-20].

2.4 Effect of heat treatment process on alloy properties

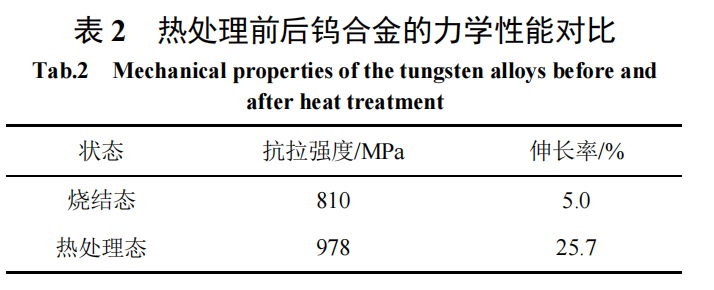

The previous research results show that when 93W-4.9Ni-2.1Fe alloy is sintered in a hydrogen atmosphere, except for the significant improvement of the tensile properties of the alloy when sintered at 1550℃, the tensile strength of the sintered tungsten alloy generally does not exceed 900 MPa when sintered at other temperatures, and the elongation is generally less than 10%. Combined with the fracture morphology analysis, in the sintered tungsten alloy, cracks initiate from the tungsten-tungsten grain interface during the tensile process and then mainly extend along the tungsten-tungsten grain and tungsten grain-binder phase interface. This is because tungsten alloys absorb hydrogen when sintered at high temperature in a hydrogen atmosphere, and the formation of intermetallic compounds in the alloy leads to a decrease in the interface bonding strength of the tungsten grain-binder phase. The 93W-4.9Ni-2.1Fe alloy prepared from 6.0 μm tungsten powder was sintered in a hydrogen atmosphere at about 1 510 ℃, and then subjected to solid solution + quenching heat treatment in a nitrogen atmosphere. The tensile properties before and after heat treatment are compared in Table 2. As shown in Table 2, the tensile strength and elongation of the 93W-4.9Ni-2.1Fe alloy were significantly improved after heat treatment, reaching 978 MPa and 25.7%, respectively, which is consistent with the research results of Ai Xuan [21].

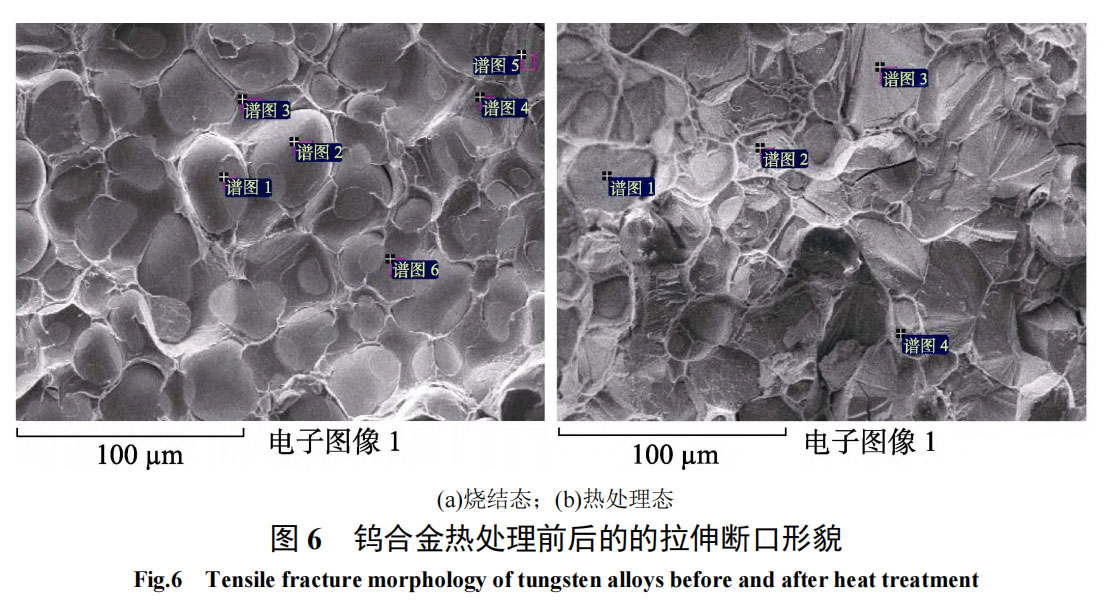

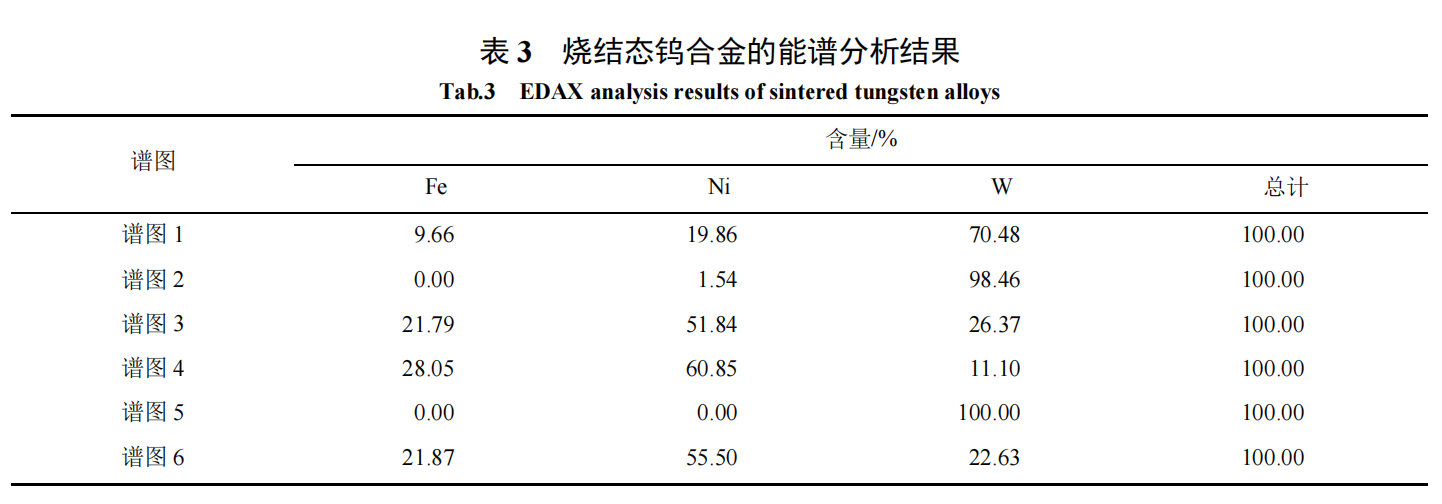

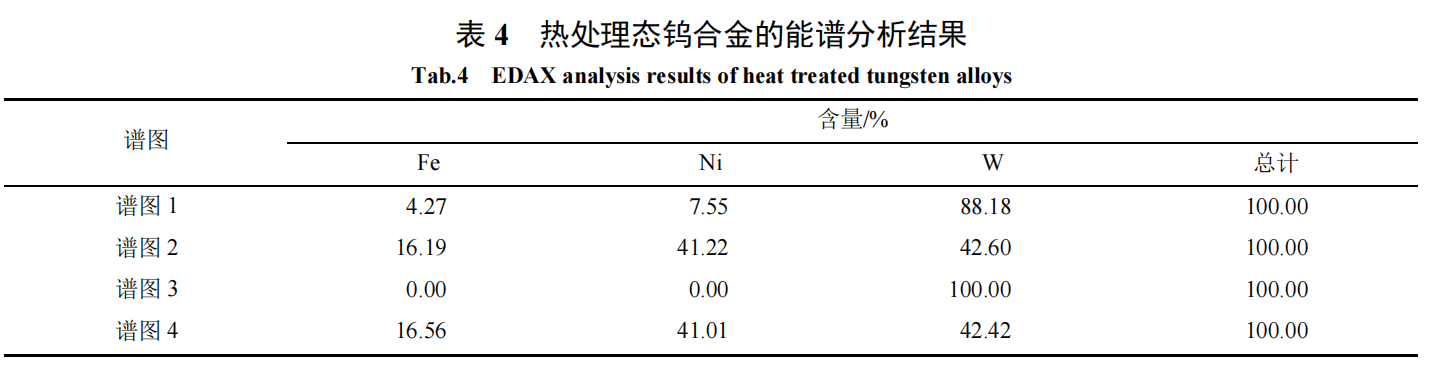

Figure 6 shows the tensile fracture morphology of the tungsten alloy before and after heat treatment, and Tables 3 and 4 are the energy spectrum analysis results of the sintered and heat treated tungsten alloys, respectively. It can be found that after heat treatment, the fracture morphology of the tungsten alloy is transgranular cleavage fracture of tungsten grains, interface separation of tungsten-tungsten grains, and ductile fracture of the bonding phase, and there is basically no interface separation of tungsten grains-bonding phase. From the graphs 3 and 4 in Table 3, it can be seen that the tungsten content of the solid solution in the bonding phase of the sintered tungsten alloy does not exceed 30%; from the graphs 2 and 4 in Table 4, it can be seen that the tungsten content of the solid solution in the bonding phase of the heat-treated tungsten alloy is as high as about 42%, indicating that the tungsten content of the solid solution in the bonding phase of the tungsten alloy is also significantly increased after heat treatment. This shows that the 93W-4.9Ni-2.1Fe alloy can be dehydrogenated and eliminate hydrogen embrittlement by sintering in a hydrogen atmosphere and then undergoing a solid solution treatment in a nitrogen atmosphere. Combined with quenching treatment, the strength of the bonding phase can be improved, thereby significantly improving the mechanical properties of the sintered tungsten alloy.

3 Conclusion

(1) When the 93W-4.9Ni-2.1Fe alloy is sintered in the temperature range of 1 415~1 550 ℃, as the sintering temperature increases, the mechanical properties of the sintered tungsten alloys prepared from the four tungsten powders with average particle sizes of 1.5 μm, 2.8 μm, 5.0 μm and 6.0 μm all show a pattern of first increasing, then decreasing and then increasing again. When sintered at about 1 500~1 510 ℃, the mechanical properties of the tungsten alloy suddenly decrease; the mechanical properties of the tungsten alloy prepared from the coarse tungsten powder are generally higher than those of the tungsten alloy prepared from the fine tungsten powder at the same sintering temperature.

(2) The mechanical properties of high-density tungsten alloys are related to their fracture behavior. Ductile fracture indicates that the tungsten grains have a high degree of transgranular cleavage fracture and bonding phase ductile fracture, while brittle tungsten alloys tend to show more tungsten grain-bonding phase interface separation. Tungsten crystalThe grain-bonding phase interface bonding strength is the key factor that determines the mechanical properties of tungsten alloy. The higher the tungsten grain-bonding phase interface bonding strength, the better the mechanical properties of tungsten alloy.

(3) After sintering in a hydrogen atmosphere, high-density tungsten alloy is subjected to solid solution + quenching heat treatment in a nitrogen atmosphere, which can effectively eliminate hydrogen embrittlement and precipitation of intermetallic compounds, improve the tungsten grain-bonding phase interface bonding strength and bonding phase strength, thereby significantly improving the tensile strength and elongation of tungsten alloy.

Paper citation information

China Tungsten Industry Vol. 37 No. 2 April 2022

W-Ni-Fe alloy powder (tungsten-nickel-iron alloy powder) is mainly used in the following fields due to its high specific gravity, excellent mechanical properties and corrosion resistance:

1. Counterweight and balancing materials

- Aerospace: used for aircraft engine blades and gyroscope counterweights to ensure balanced operation.

- Petroleum industry: manufacturing drilling tool counterweights to enhance equipment stability.

2. Radiation shielding materials

- Medical field: replace lead, make shielding parts for CT machines and radiotherapy equipment, with both environmental protection and high strength advantages.

- Nuclear industry: used for radiation protection shells of nuclear reactors.

3. Military industry and high-end manufacturing

- Armor-piercing core: use high hardness and density to make kinetic cores to penetrate armored targets.

- Precision molds: manufacture die-casting molds to adapt to high temperature and high pressure conditions.

4. Electronics and thermal management

- Heat sink materials: used for chip heat dissipation substrates, using high thermal conductivity to quickly export heat.

- Electrical contact parts: make high-reliability relay contacts and resist arc corrosion.

5. 3D printing and powder metallurgy

- Metal additive manufacturing: as printing raw materials, directly forming complex structural parts (such as aircraft engine parts).

- Sintered products: prepare high-density mechanical parts through powder metallurgy process to reduce processing losses.

- http://en.stardusttech.cn/products/107.html

For more powder details, please contact Vicky at +86-13318326185

News