Mo-Re alloy powder cold isostatic pressing forming law

Release time:

2025-06-16

Molybdenum metal has the advantages of high temperature resistance, low vapor pressure, small coefficient of thermal expansion, and good electrical and thermal conductivity. However, pure molybdenum is a typical body-centered cubic structure, there are poor low-temperature ductility, low recrystallization temperature, recrystallization is brittle and other obvious defects, due to the recrystallization brittleness directly affects the service life and reliability of the device, to a large extent, to limit the application of its high-temperature structural components [1-2]. Rhenium metal has the advantages of high melting point (3170℃), high density (21.02g-cm-3), high strength, good plasticity, high modulus of elasticity. The addition of rhenium to molybdenum will form the “rhenium effect”, which significantly improves the room temperature brittleness of molybdenum and enhances the material strength, creep resistance, processability, physicochemical and thermoelectric properties, etc. [2-5]. Molybdenum-rhenium alloys are widely used in propellers, heaters, structural jacket materials for nuclear fields, engine sealing elements and other fields [6-8]. Molybdenum rhenium alloys are mainly prepared by melting and powder metallurgy. Compared with the melting method, the powder metallurgy process of the alloy billets obtained from the fine and uniform grain, impurities in the grain boundaries of the segregation is not serious, impurities less harmful, conducive to the subsequent processing, the metal recovery rate is high. For small quantities, small specifications of products, powder metallurgy method has greater flexibility, so the vast majority of molybdenum rhenium alloy products are prepared using powder metallurgy methods.

Powder molding is one of the key processes in the powder metallurgy process, by pressing the raw material powder into a certain shape, size and density of the billet. With the increase of rhenium content in molybdenum alloy, the work hardening rate of the alloy is significantly increased, the alloy powder pressing and forming process, it is easy to appear billet cracking failure. Once the formation of cracks within the billet, there is basically no way to repair, and this will affect the final mechanical properties of the alloy. Domestic research on molybdenum-rhenium alloys focuses on low rhenium-molybdenum alloys, and less research on high-rhenium-molybdenum alloys [9-11]. Powder molding research includes two aspects: one is the theoretical derivation of mathematical equations for powder molding; the second is to reflect the degree of densification of powder in the pressing process through the powder molding process [12]. In the theory of pressing equations derived from the molding method, the “Huang Peiyun double natural logarithmic equation” applies to both soft and hard powders, and is equally applicable to isostatic pressing or uniaxial axial pressing [13]. In this paper, the differences in cold isostatic pressing of Mo-47.5%Re ball-milled alloy powder and plasma spheroidized alloy powder are compared and analyzed, and the pressing parameters are fitted by “Huang Peiyun's double natural logarithmic equation” from the theory of derivation of mathematical equations for powder forming.

1 Experimental materials and methods

molybdenum powder, ammonium rhenate as raw materials, according to the Mo-47.5% Re ratio (mass fraction) for ball milling and mixing. Mo powder selection of high-purity molybdenum powder provided by Luoyang Jianyu Limited, the purity of 99.9%, the median particle size (D50) of 5.3 μm. Ammonium rhenate selection of high-purity rhenium rhenate made by the Chongqing Institute of Materials Research Co. Ltd. with a purity of 99.9%. The preparation process of ball milling mixing alloy powder is shown in Figure 1. The molybdenum powder and ammonium rhenate crystals in the ball milling irrigation, molybdenum ball as a grinding ball for high-energy ball milling mixing, mixing time 15h. Subsequently, the mixed raw materials in a reducing atmosphere for roasting, so that the ammonium rhenate decomposition of ammonium rhenate fully, the roasting temperature of 400 ℃, time 3h. Will be roasted raw materials and then mixing, mixing time of 15h. Will be mixed again powder reduction, the reduction temperature 1100 ℃, time 3h, to obtain the ball milling mixing process. Time 3h, to get the ball mill mixing alloy powder. Take part of the ball milling mixing alloy powder in Teksphero plasma spheronizer produced by Tekna company for spheronization, in which the feeding speed of 3kg-h-1, plasma power of 40kW, the carrier gas flow rate of 4L-min-1, to get the plasma spheronization of alloy powder.

The ball-milled mixed alloy powder and plasma spheroidized alloy powder were loaded into ϕ30mm×50mm and ϕ30mm×320mm rubber die sets, respectively, and placed in Shanghai Haopouli CIP500/2000 cold isostatic press for pressing and forming, with the pressing pressure of 130-250MPa and the holding time of 300s. The relationship between the pressing pressure and the density of the briquette, as well as a comparison of the pressing effect, were analyzed, in which the density of briquettes was compared using the wax sealing. In which the density of the press blanks was tested by utilizing the drainage method after wax sealing [14]. The particle size distribution and micro-morphology of the alloy powder were analyzed by using Bettersize2000 laserparticlesizeanalyzer (LPSA) and TESCAN VEGA3 scanning electron microscope (SEM), and the particle size distribution and micro-morphology of the alloy powder were analyzed by using Hall A Hall flow meter was used to determine the powder bulk density and flow velocity.

Cold isostatic pressing forming law of Mo-Re alloy powder

Molybdenum metal has the advantages of high temperature resistance, low vapor pressure, small coefficient of thermal expansion, and good electrical and thermal conductivity. However, pure molybdenum is a typical body-centered cubic structure, there are poor low-temperature ductility, low recrystallization temperature, recrystallization is brittle and other obvious defects, due to the recrystallization brittleness directly affects the service life and reliability of the device, which largely restricts its application in high-temperature structural components [1-2]. Rhenium metal has the advantages of high melting point (3170℃), high density (21.02g-cm-3), high strength, good plasticity, high modulus of elasticity. The addition of rhenium to molybdenum will form the “rhenium effect”, which significantly improves the room temperature brittleness of molybdenum and enhances the material strength, creep resistance, processability, physicochemical and thermoelectric properties, etc. [2-5]. Molybdenum-rhenium alloys are widely used in propellers, heaters, structural jacket materials for nuclear fields, engine sealing elements and other fields [6-8]. Molybdenum rhenium alloys are mainly prepared by melting and powder metallurgy. Compared with the melting method, the powder metallurgy process of the alloy billets obtained from the fine and uniform grain, impurities in the grain boundaries of the segregation is not serious, impurities less harmful, conducive to the subsequent processing, the metal recovery rate is high. For small quantities, small specifications of products, powder metallurgy method has greater flexibility, so the vast majority of molybdenum rhenium alloy products are prepared using powder metallurgy methods.

Powder molding is one of the key processes in the powder metallurgy process, by pressing the raw material powder into a certain shape, size and density of the billet. With the increase of rhenium content in molybdenum alloy, the work hardening rate of the alloy is significantly increased, the alloy powder pressing and forming process, it is easy to appear billet cracking failure. Once the formation of cracks within the billet, there is basically no way to repair, and this will affect the final mechanical properties of the alloy. Domestic research on molybdenum-rhenium alloys focuses on low rhenium-molybdenum alloys, and less research on high-rhenium-molybdenum alloys [9-11]. Powder molding research includes two aspects: one is the theoretical derivation of mathematical equations for powder molding; the second is to reflect the degree of densification of powder in the pressing process through the powder molding process [12]. In the theory of pressing equations derived from the molding method, the “Huang Peiyun double natural logarithmic equation” applies to both soft and hard powders, and is equally applicable to isostatic pressing or uniaxial axial pressing [13]. In this paper, the differences in cold isostatic pressing of Mo-47.5%Re ball-milled alloy powder and plasma spheroidized alloy powder are compared and analyzed, and the pressing parameters are fitted by “Huang Peiyun's double natural logarithmic equation” from the theory of derivation of mathematical equations for powder forming.

2 Results and analysis

2.1 Alloy powder morphology and particle size distribution

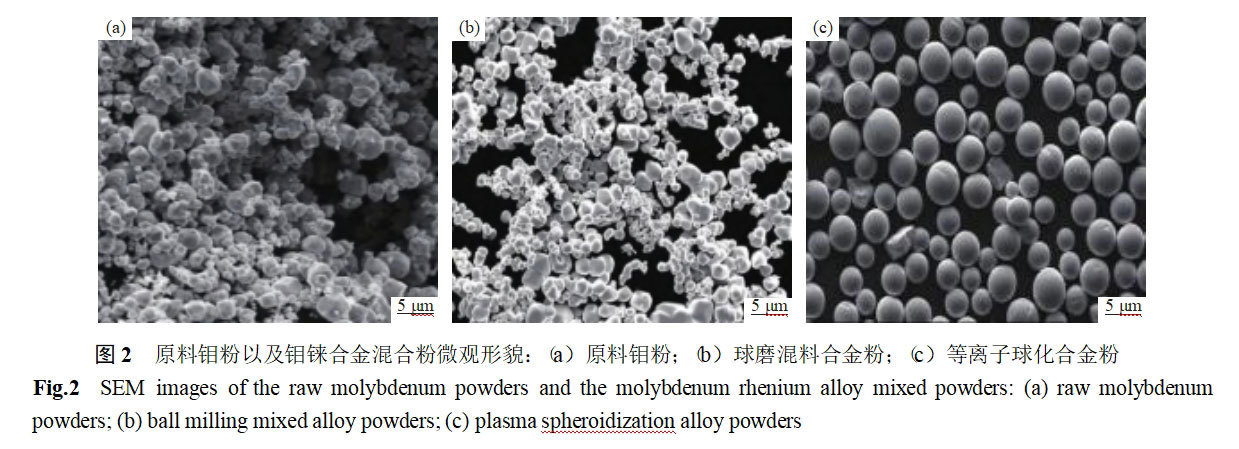

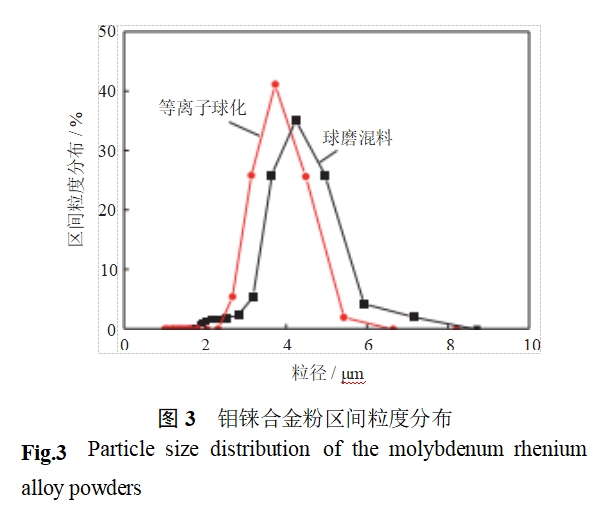

The micro-morphology of raw material powder and alloy powder is shown in Figure 2. Figure 2 (b) for the ball milling mixing alloy powder, as can be seen from the figure, the powder is irregular shape with corners, compared with Figure 2 (a) molybdenum powder, the corners are obviously reduced, and some agglomeration bonding phenomenon. This is because in the process of high-energy ball milling, the powder particles and grinding ball for intense impact, collision and accompanied by inter-particle cold welding and fracture [15], so that the inter-particle stress concentration occurs at the abrasion and the angularity of the reduction of the inter-particle surface energy of the higher agglomerative bonding occurs. Combined with the interval particle size distribution in Figure 3, it can be seen that the median particle size D50 of the alloy powder of the ball milling mix is 4.2 μm, which is lower than that of the molybdenum powder in the raw material of 5.3 μm. This is due to the collision and abrasion of particles with particles as well as between particles and milling balls in the process of high-energy ball milling, so that some of the larger particles are broken, which in turn reduces the average particle size of the powder. Figure 2(c) shows the microscopic morphology of the plasma spheronized alloy powder. From the figure, it can be seen that after plasma spheronization, the particles have high sphericity, which is closely related to the plasma power and powder feeding speed [16]. In addition, combined with Figure 3, it can be seen that the median particle size D50 of the powder after plasma spheronization is slightly smaller, 3.8 μm, and the particle size distribution interval is slightly narrower. This is due to the plasma spheronization process, large particles melt into large droplets when entering the plasma high temperature zone, and when moving with the working gas, they are decomposed into multiple droplets under their own surface tension and the action of external gases, and then cooled into multiple small spherical particles, so that the average particle size decreases. At the same time, part of the very fine powder in the plasma area directly melting gasification, with the working gas migration to the back end of the spheronizer collector, so the performance of the spheronization of the powder after the narrowing of the particle size distribution area.

2.2 Comparison of pressing effect

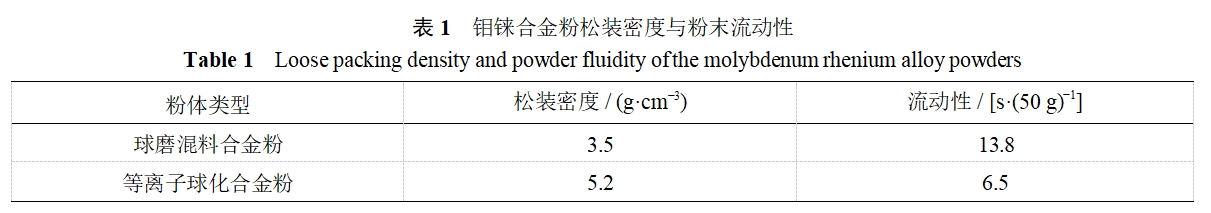

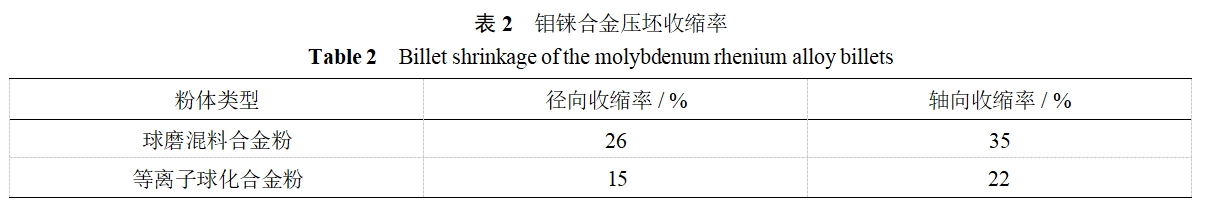

The ball milling mix alloy powder and plasma spheroidizing alloy powder are placed in a rubber die sleeve of ϕ30mm×320mm, and cold isostatic pressing is carried out at 250MPa for 300s, and the morphology of the pressed briquettes after pressing is shown in Fig. 4. From Fig. 4, it can be seen that the plasma spheroidized alloy powder is complete and uncracked after pressing, while the ball-milled alloy powder is fractured with multi-segmented bamboo joints after pressing. The two alloy powders were tested for loose packing density and fluidity and the results are shown in Table 1. From Table 1, it can be seen that after plasma spheroidization of the ball-milled blended alloy powders, the bulk density and fluidity of the alloy powders were significantly increased. This is due to the spheroidization, the powder morphology from the angular irregular shape to a spherical shape, the contact area between the particles is reduced, the frictional resistance is reduced, and the stacking is denser. Table 2 shows the test results of the shrinkage of the compression billet. From Table 2, it can be seen that the axial shrinkage is greater than the radial shrinkage in the pressing process of both alloy powders. This is due to the fact that when the length-diameter ratio is larger, the pressure acts with more powder along the axial direction and is accompanied by the displacement and deformation of the powder particles, which reduces the inter-pore space between the powders. After plasma spheroidization, both radial and axial shrinkage were significantly lower than that of the ball-milled blended alloy powders, which was due to the spherical shape of the spheroidized powder, fewer inter-particle pores, larger contact area, increased bulk density, and more spherical powder loaded into the die sleeve.

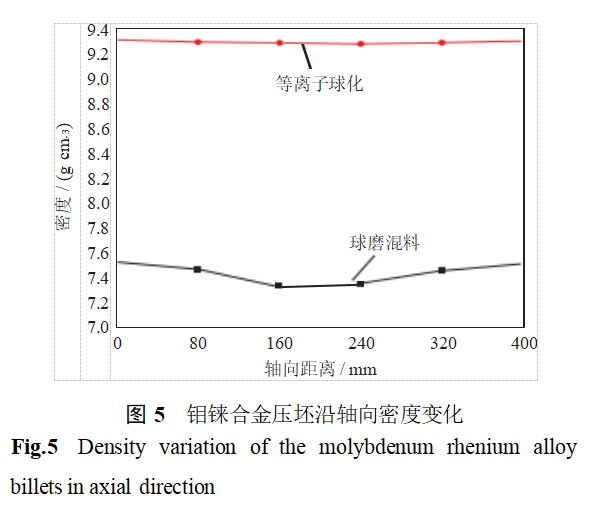

The briquette is cut along the axial direction and the density of each section of the briquette is analyzed, and the change in the density of the briquette along the axial direction is shown in Figure 5. From the figure, it can be seen that the density of plasma spheroidized alloy powder briquette varies less along the axial direction, and the density of the core is slightly lower than the density of the ends. The density of ball-milled blended alloy powder billet has a large variation along the axial direction, and the core density is significantly lower than the density at both ends. There is a change in the density of the billet along the axial direction because there is a longer transfer of pressure along the axial direction during the cold isostatic pressing process, accompanied by internal friction between the powder and friction between the powder and the mold wall, resulting in a larger pressure loss along the axial direction. For plasma spheroidized alloy powder, due to its high sphericity, small inter-particle gap, and large contact area, the powder in the pressing process gradually becomes surface contact from the initial point contact, and the powder particles form a mechanical engagement between them. And because the contact area between the powder is larger, the pressure loss caused by the friction between the particles is reduced, which in turn is manifested in the high strength of the press blank and the density of the press blank along the axial change is small. For ball milling mixing alloy powder, the inter-particle pores are more, the pressing process along the axial direction to produce a larger pressure loss, while the elastic internal stress accumulated in the powder along the axial direction there is also a large difference. When the pressing pressure is unloaded, the elastic internal stress relaxes, changing the molybdenum rhenium powder particle shape and contact state, so that the billet expansion occurs. For Mo-47.5% Re pre-alloyed powder, due to the elastic modulus of Re (463 GPa) and Mo's elastic modulus (329 GPa) there are large differences in the axial direction due to elastic aftereffects of deformation there are also large differences. When the force formed by mechanical meshing between the particles cannot offset the stress generated by axial elastic aftereffects, the bamboo-like fracture will occur.

2.3 Alloy Powder Forming Laws

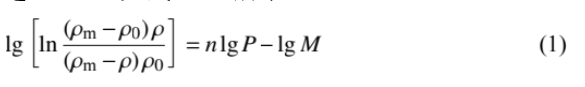

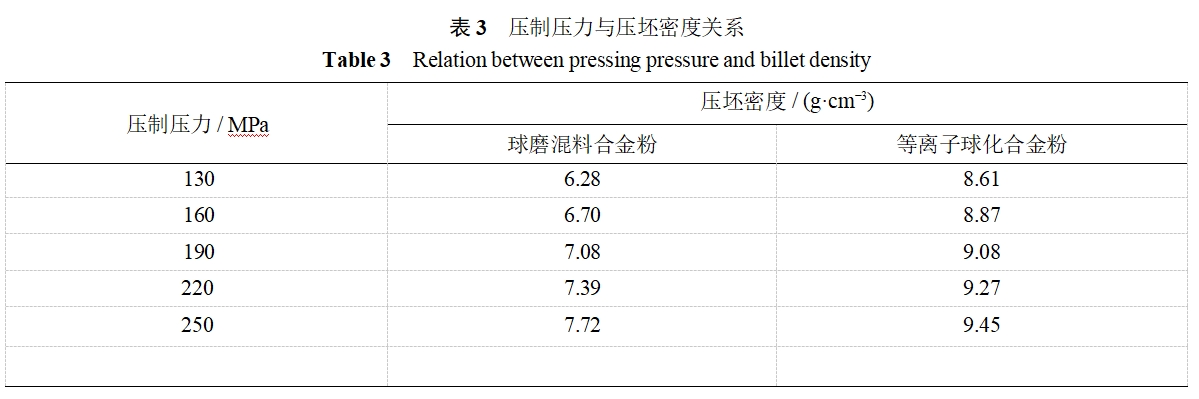

The cold isostatic pressing of ball-milled alloy powder and plasma spheroidized alloy powder with different pressures was carried out, and the relationship between the pressing pressure and the density of the briquettes is shown in Table 3. It can be seen that with the increase of the pressing pressure, the briquette densities of the two kinds of alloy powders show a tendency to become larger. In order to further investigate the relationship between the pressing pressure and the density of the billet, the “Huang Peiyun double logarithmic pressing theory” is used to analyze, which takes into account the non-elastic characteristics of the powder body and the large changes in strain during the pressing and forming. The isostatic pressing pressure and the density of the billet can be described by the pressing double logarithmic equation [13-14,17], as shown in equation (1).

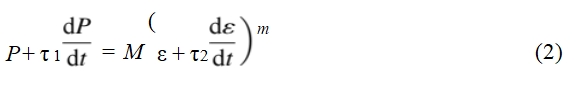

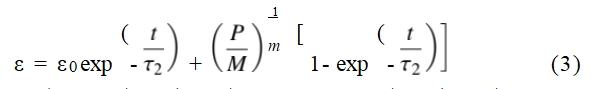

where: ρ0 is the original density of the briquette, g-cm-3; ρ is the density of the briquette, g-cm-3; ρm is the density of the dense metal, g-cm-3; P is the pressing pressure, MPa; n is the inverse of the hardening exponent, and no hardening occurs when n=1; M is the pressing modulus, MPa Professor Huang Peiyun further developed the double logarithmic equation and analyzed the equation (1), pointing out that the magnitude of M is the same as that of Pn, and it is difficult to compare the magnitude of M of different powders due to the different values of n and M, and thus the different powders are different. If the mathematical model of Eq. (2) is used instead, the above equation is solved under the condition of maintaining constant pressure (dP/dt=0), and Eq. (3) can be obtained.

Where: τ1 is the stress relaxation time, s; τ2 is the strain relaxation time, s; t is the pressing time, s; ε is the strain, %; ε0 is the initial strain, %; m is the hardening index.

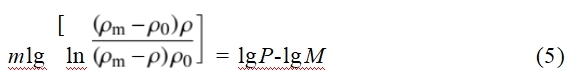

In the case of full relaxation, exp(-t/τ2) → 0, which has the relationship shown in Eq. (4), where ε = ln[(ρm-ρ0)ρ/(ρm-ρ)ρ0].

After taking logarithms on both sides of Eq. (4) and applying the natural strain concept, Eq. (5) is obtained. From Eq. (5), lg{ln[(ρm-ρ0)ρ/(ρm-ρ)ρ0]} is in a linear relationship with lgP, and if the former is taken as the horizontal coordinate and the latter is taken as the vertical coordinate, the slope of the resulting straight line will be the value of m, and the intercept between the straight line and the vertical axis will be the value of lgM.

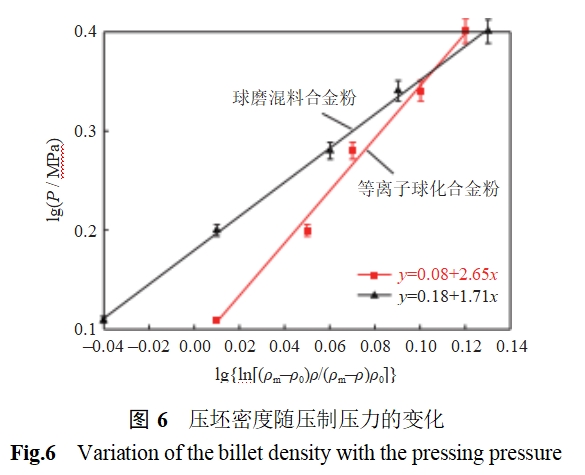

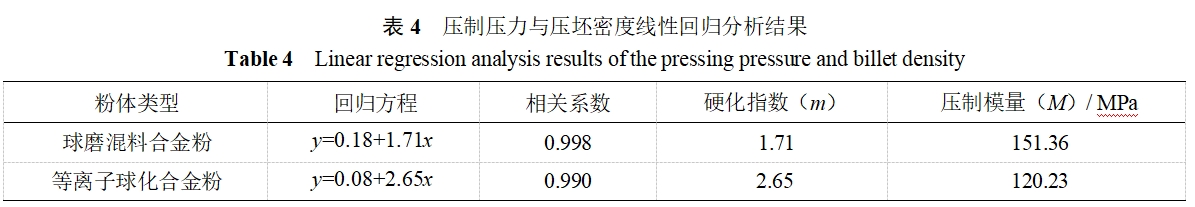

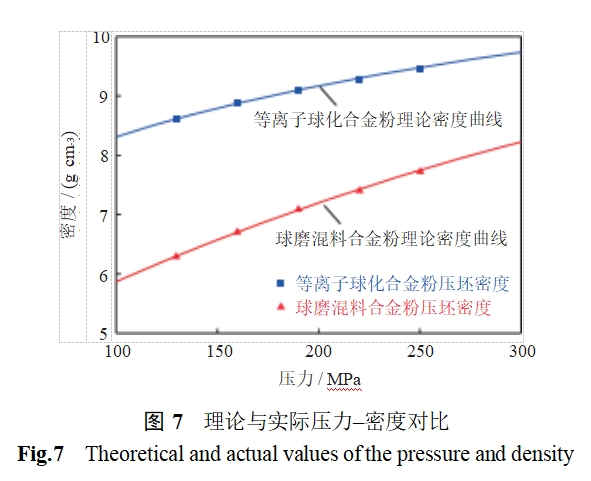

The data in Table 3 were applied to Eq. (5) for linear fitting, where ρ0 is the initial density of the alloy powder, and the charge was not vibrated for this experimental loading, so the loading density was treated as the loosely loaded density, and the loosely loaded densities of the ball-milled blended alloy powder and the plasma spheroidized alloy powder were 3.5 g-cm-3 and 5.2 g-cm-3, respectively, and ρm= 13.52 g-cm-3. The fitting results are shown in Fig. 6. From Fig. 6, it can be seen that the two kinds of alloy powders are in good conformity with the “double logarithmic equation”. The results of the linear regression analysis between the pressing pressure and the density of the briquette of the two alloy powders are shown in Table 4. From the table, it can be seen that the correlation coefficient of the regression equation is between 0.990 and 0.998, indicating that the straightness of the fit is good. Among them, the hardening index of plasma spheroidized alloy powder is slightly higher than that of ball-milled blended alloy powder, indicating that the hardening tendency of plasma spheroidized alloy powder is greater, which indicates that during the pressing process of plasma spheroidized alloy powder, the powder particles, in addition to the relative movement and pore filling, have greater plastic deformation. This is due to the large contact area between the spherical powders, less inter-particle voids, when the pressure is transferred to the spherical powders, the displacement space of the powder is limited, and more plastic deformation of the powder is produced, which in turn leads to a higher hardening index of the spherical powders. This is consistent with the law reflected by the fact that spherical powders have a high bulk density, large contact area between particles in the pressing process, and less change in the density of the pressurized blank along the axial direction. In addition, the pressing modulus (M) of plasma spheroidized alloy powders is lower than that of ball-milled blended alloy powders, indicating that they are easier to press compared to ball-milled blended alloy powders [18]. Pressing modulus includes pressure loss, and during the pressing deformation process, spherical powders have fewer inter-pore spaces, larger inter-particle contact area, and less pressure loss due to friction during the pressing process. Pressure loss is the main reason for the uneven density distribution of the briquette, and also the main reason for the briquette cracking, the spherical alloy powder in the pressing process less pressure loss makes it easier to press molding compared with the mechanical mixing alloy powder. Figure 7 converts the “double logarithmic equation” into a pressure-density curve and compares it with the actual density of the briquette. As can be seen from the figure, the two powder pressure-density curve are nearly parabolic, which is consistent with the empirical law of the pressing process, and the actual billet density distribution in the vicinity of the curve, indicating that the theoretical curve better responds to the changing law of billet pressure density.

3 Conclusion

(1) cold isostatic pressing in the larger diameter mold, ball mill mix and plasma spheroidized molybdenum rhenium alloy powder after pressing are shown in the billet axial shrinkage is greater than the radial shrinkage. Two kinds of powder in 250MPa, holding pressure after 300s, ball milling mix alloy powder radial shrinkage of 26%, axial shrinkage of 35%; plasma spheroidized alloy powder radial shrinkage of 15%, axial shrinkage of 22%.

(2) in the length and diameter of the larger mold for cold isostatic pressing, plasma spheroidized molybdenum rhenium alloy powder billet complete, not cracked, billet density along the axial change is less, the core density is slightly lower than the density of the two ends. Ball milling mix alloy powder billet was bamboo fracture, billet density along the axial direction, there are large changes in the core density is significantly lower than the density at both ends.

(3) The relationship between the pressing pressure and the density of the briquette was analyzed by using the “Huang Peiyun double logarithmic pressing theory”, and it was found that the hardening index of the plasma spheroidized alloy powder was slightly higher than that of the ball-mill mixture alloy powder, and the pressing modulus was lower than that of the ball-mill mixture alloy powder, which indicated that the hardening tendency of the plasma spheroidized alloy powder was greater, and the plasma spheroidized alloy powder was more easy to be pressed than that of the ball-mill mixture alloy powder.

Ref: February 2025, Volume 43, Issue 1 Powder Metallurgy Technology Cold Isostatic Pressing Forming Laws for Mo-Re Alloy Powders

Spherical molybdenum rhenium alloy powders have a high melting point, excellent high-temperature strength, and creep resistance, which makes them suitable for industrial applications in extreme environments. Its uniform spherical particle morphology improves flowability and packing density, which is outstanding in the fields of 3D printing, aerospace engine parts and electronic packaging. Stardust Technology (Guangdong) Co., Ltd. focuses on the research, development and production of high-performance metal powders, providing customers with stable and reliable material solutions through stringent quality control and customized services, helping precision manufacturing and technological innovation. For any inquiries about rare refractory metal powders, please feel free to contact our professional technicians (Manager Zheng +86 13318326187), we will be happy to answer your questions.