-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Study on the recrystallization annealing temperature of Ta-10W alloy

Release time:

2025-06-05

1 Introduction

Ta and W are both high-density, rare and refractory metals, among which Ta has the advantages of high melting point, good mechanical properties, high thermal conductivity, good chemical stability and strong corrosion resistance [1]. The Ta-10W alloy developed by combining the characteristics of the two has the advantages of high density, high strength, high temperature resistance, low plastic-brittle transition temperature and stable chemical properties. It has been successfully applied to high-temperature aerospace structural materials, high-temperature vacuum furnace components, high-temperature springs, thermal shielding and liquid fuel rocket nozzles that need to withstand temperatures up to 3316℃. In addition, it can also be used to make spring valves for various water treatment and chlorination equipment and acid-resistant springs in petrochemical equipment, which has a good application prospect.

The preparation methods of Ta-10W alloy mainly include powder metallurgy and electron bombardment melting [1]. Since the electron bombardment melting method can effectively remove various impurities in the material (especially harmful low-melting point impurities) and the relative density of the ingot is significantly higher than that of the ingot produced by the powder metallurgy method [2], it is often used in the industrial production of Ta-10W alloy ingots. However, the coarse grains of the ingots produced by the electron bombardment melting method are not conducive to the mechanical properties of the material. It is necessary to refine the grains through processing deformation and combined with recrystallization annealing to improve the material's organizational structure and improve the processing performance and mechanical properties [3].

This paper specifically studies the recrystallization annealing process of the alloy bars of Ta-10W ingots produced by electron bombardment melting after extrusion, blanking and cold processing.

2 Experimental process

2.1 Preparation of Ta-10W alloy ingot

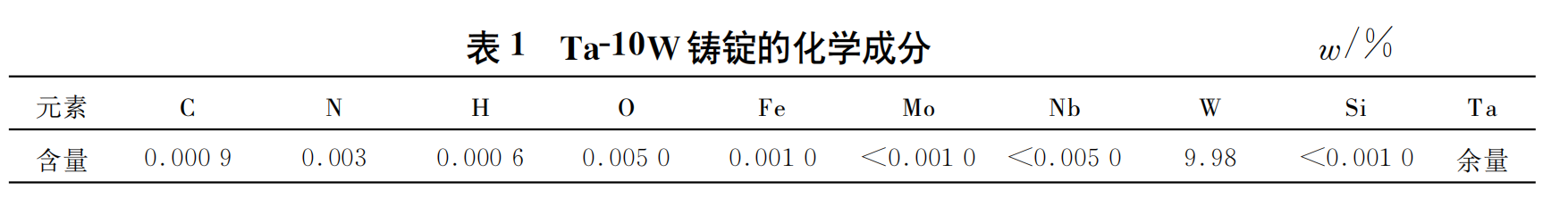

The preparation process of Ta-10W alloy ingot can be briefly summarized as: tantalum powder + tungsten powder → mixing → isostatic pressing → vacuum vertical melting sintering → electron bombardment melting → D100mm Ta-10W ingot The grains of the ingot obtained are relatively coarse, and the average surface grain size is 4-6mm. The chemical composition analysis results of the ingot are shown in Table 1.

2.2 Ta-10W alloy ingot blanking

Because the grains of Ta-10W alloy ingot obtained by electron bombardment melting are coarse, in order to fully break the coarse casting structure for subsequent processing. This experiment uses high-temperature extrusion blanking with large deformation. It is well known that tantalum and its alloys are very sensitive to hydrogen and oxygen at high temperatures. Therefore, heating must be carried out in a neutral or inert atmosphere. However, due to equipment limitations, this experiment uses high-temperature glass powder as a protective coating and a medium-frequency segmented rapid heating method to control the oxidation absorption layer. During the heating process, the temperature is monitored by an infrared non-contact thermometer. When the ingot temperature rises to 1200-1250℃, it is kept warm for 10-15 minutes and then extruded by a 1600-ton extruder to obtain a D32mm extruded rod, which is then peeled by a lathe to obtain a D30mm rod blank.

Ta-10W alloy hardens quickly. If the extrusion is carried out at a low heating temperature, the extruder may be blocked due to excessive resistance to deformation; if the heating temperature is too high, the grains inside the material will grow and even the grain boundaries will melt, resulting in a decrease in the plasticity of the material. Therefore, the heating temperature of the ingot should be strictly controlled to avoid changes in the material processing performance and comprehensive material performance caused by too high or too low temperature.

2.3 Recrystallization annealing of Ta-10W alloy

Five samples were taken from D30mm bar billets and vacuum annealed at 1350℃, 1400℃, 1450℃, 1500℃ and 1550℃ respectively. The holding time was 60min. Then the samples were tested for hardness and metallographic observation. The recrystallization of Ta-10W alloy was analyzed based on the hardness change trend and metallographic structure. In order to study the effect of cold working on the recrystallization of Ta-10W alloy, the D30mm bar billets after vacuum annealing at 1500℃×60min were cold deformed to D14mm with a total processing rate of 78%. Samples were taken from this D14 mm bar and vacuum annealed at 1350℃, 1400℃, 1450℃, 1500℃ and 1550℃ respectively. The holding time was still 60min. Then the mechanical properties of the samples were tested and the recrystallization was analyzed by metallographic observation.

3 Results and discussion

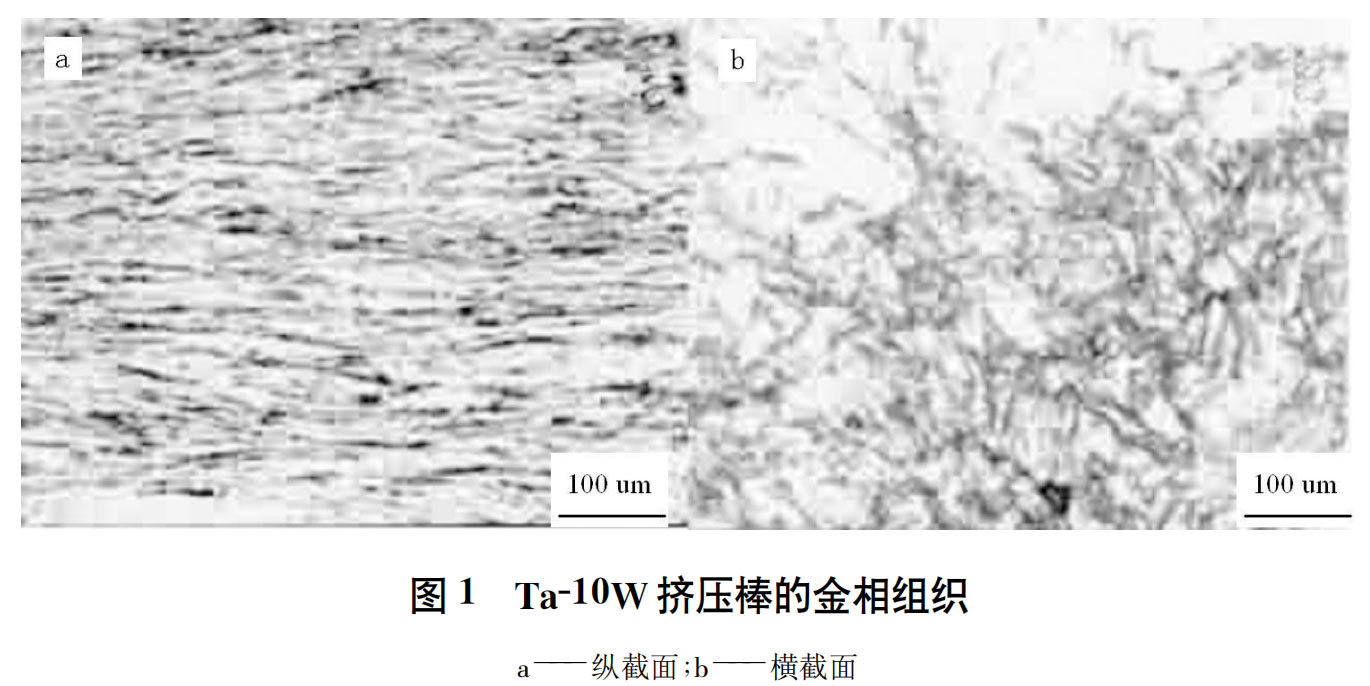

3.1 Recrystallization annealing temperature of Ta-10W alloy extruded rod Figure 1 is a metallographic microstructure photo obtained by analyzing the D30mm extruded rod billet. It can be seen that the longitudinal and cross-sectional structures of the billet are fibrous, that is, the Ta-10W alloy did not undergo recrystallization when extruded in the range of 1200-1250℃, but maintained an obvious processed state group.

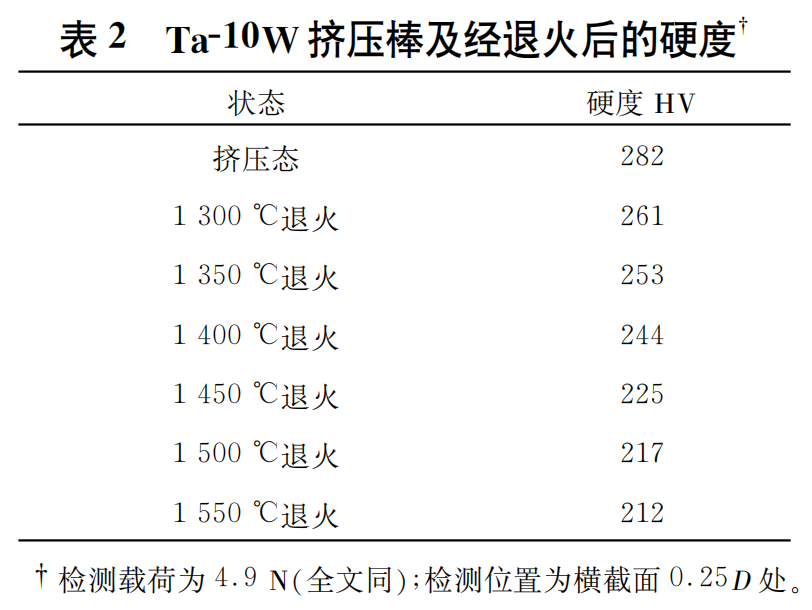

The hardness test results of the D30mm extruded rod and the samples after annealing at different temperatures are shown in Table 2.

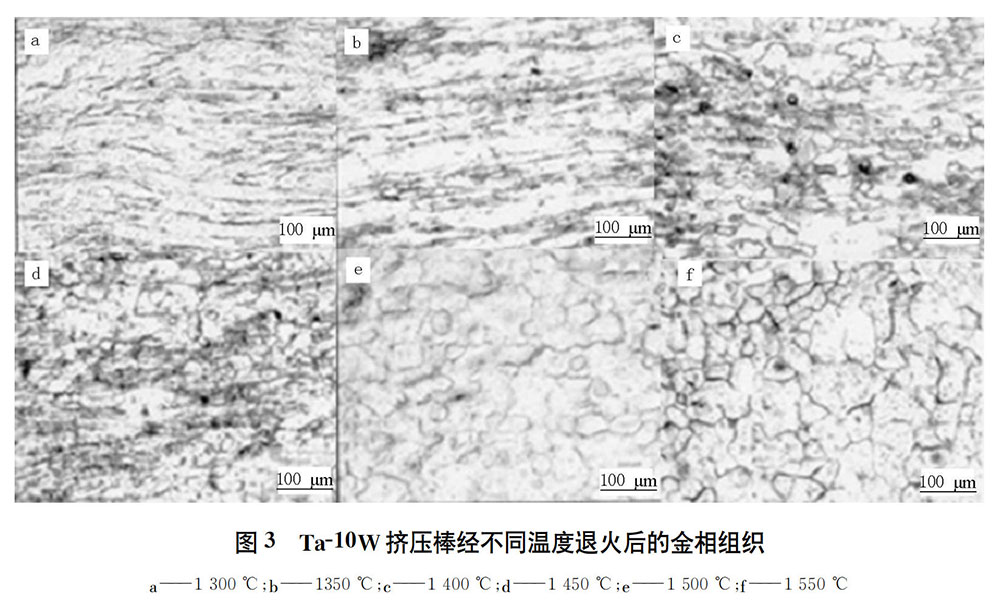

According to the data in Table 2, the annealing temperature-hardness relationship curve is drawn, as shown in Figure 2. It can be seen from the figure that the hardness of the extruded rod drops sharply in the range of 1400-1500℃, so it is determined that the sample may begin to recrystallize in this range. In order to further analyze the recrystallization of the sample structure, the metallographic microstructure at different annealing temperatures was observed, and the results are shown in Figure 3. As can be seen from Figure 3, after annealing at 1300-1350℃, there is almost no change in the microstructure of the sample. The grains still maintain the elongated fibrous structure; after annealing at 1400-1450℃, new small grains have appeared in the elongated fibrous structure, but some processed structures are still retained, indicating that the structure has begun to partially recrystallize within this temperature range; after annealing at 1500-1550℃, the fibrous structure is completely changed into new equiaxed grains, indicating that the structural recrystallization has been completed.

According to the data in Table 2, the annealing temperature-hardness relationship curve is drawn, as shown in Figure 2. It can be seen from the figure that the hardness of the extruded rod drops sharply in the range of 1400-1500℃, so it is determined that the sample may begin to recrystallize in this range. In order to further analyze the recrystallization of the sample structure, the metallographic microstructure at different annealing temperatures was observed, and the results are shown in Figure 3. As can be seen from Figure 3, after annealing at 1300-1350℃, there is almost no change in the microstructure of the sample. The grains still maintain the elongated fibrous structure; after annealing at 1400-1450℃, new small grains have appeared in the elongated fibrous structure, but some processed structures are still retained, indicating that the structure has begun to partially recrystallize within this temperature range; after annealing at 1500-1550℃, the fibrous structure is completely changed into new equiaxed grains, indicating that the structural recrystallization has been completed.

It can be seen that the recrystallization annealing temperature of the Ta-10W rod heated at 1200-1250℃ and extruded and blanked is 1500℃.

3.2 Recrystallization annealing temperature of Ta-10W alloy cold-deformed rod

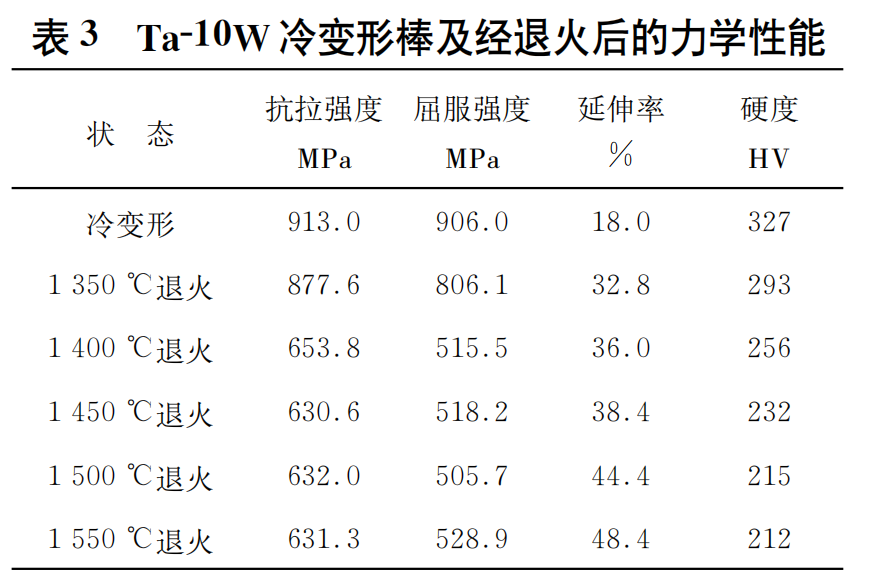

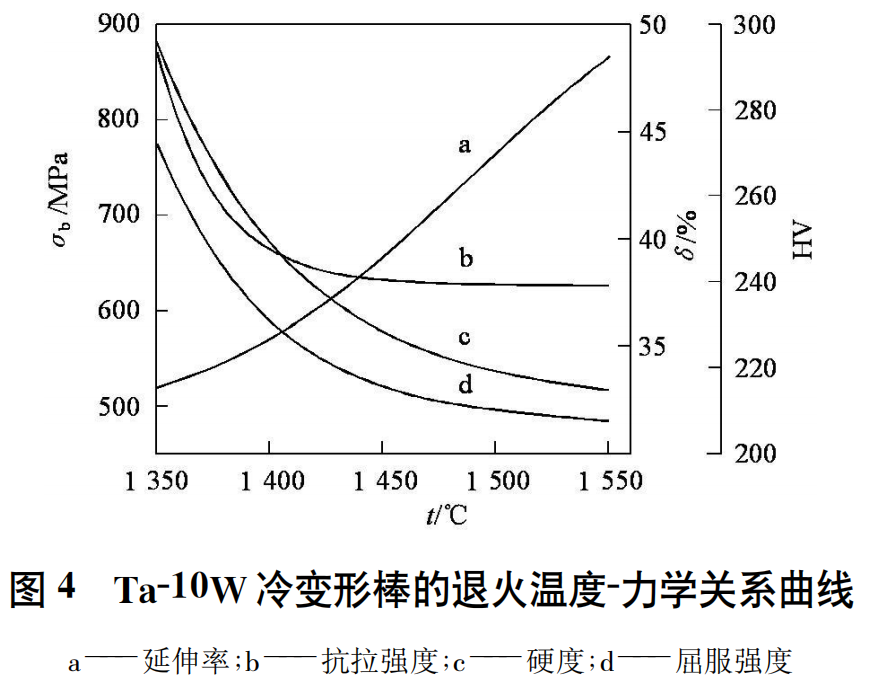

The mechanical properties test results of the D14mm Ta-10W alloy rod cold-deformed with a total processing rate of 78% and the samples after annealing at different temperatures are shown in Table 3. According to the data in Table 3, the annealing temperature-mechanical relationship curve is plotted as shown in Figure 4. From Table 3 and Figure 4, it can be seen that after the cold-deformed rod is annealed at 1350-1400℃, its tensile strength, yield strength and hardness decrease rapidly, and the elongation increases greatly. It can be determined that the cold-deformed rod begins to recrystallize at this temperature; and after annealing at 1450℃, its strength and hardness changes tend to be gentle, so it can be determined that the cold-deformed rod has reached a complete recrystallization state at this temperature.

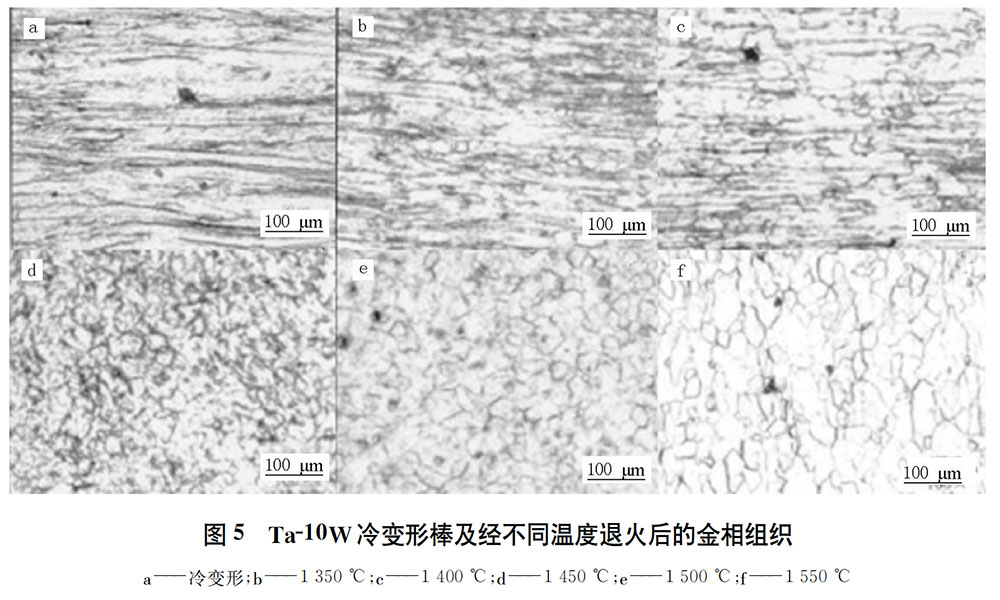

Similarly, the metallographic structure of the cold-deformed rod after different annealing processes was observed, and the results are shown in Figure 5. As can be seen from Figure 5, after the sample is annealed at 1400℃, new small grains appear in the fiber structure after cold working, which indicates that the structure has partially recrystallized, but the crystallization is not sufficient; after annealing at 1450℃, the processed structure after cold working has been completely eliminated, and all of them have formed fine equiaxed crystals, which indicates that the recrystallization has been basically completed. Therefore, after the Ta-10W alloy extruded rod is cold deformed by 78%, its recrystallization annealing temperature is 1450℃.

Similarly, the metallographic structure of the cold-deformed rod after different annealing processes was observed, and the results are shown in Figure 5. As can be seen from Figure 5, after the sample is annealed at 1400℃, new small grains appear in the fiber structure after cold working, which indicates that the structure has partially recrystallized, but the crystallization is not sufficient; after annealing at 1450℃, the processed structure after cold working has been completely eliminated, and all of them have formed fine equiaxed crystals, which indicates that the recrystallization has been basically completed. Therefore, after the Ta-10W alloy extruded rod is cold deformed by 78%, its recrystallization annealing temperature is 1450℃.

4 Conclusion

4 Conclusion

Through this test and the analysis of the test results, the following

two conclusions can be drawn:

(1) The recrystallization annealing temperature of the Ta-10W rod that is heated at 1200-1250℃ and extruded is 1500℃.

(2) After the Ta-10W alloy extruded rod is cold deformed with a total processing rate of 78%, its recrystallization annealing temperature is 1450℃.

Paper citation information

Volume 36, Issue 2, June 2008 Rare Metals and Cemented Carbides

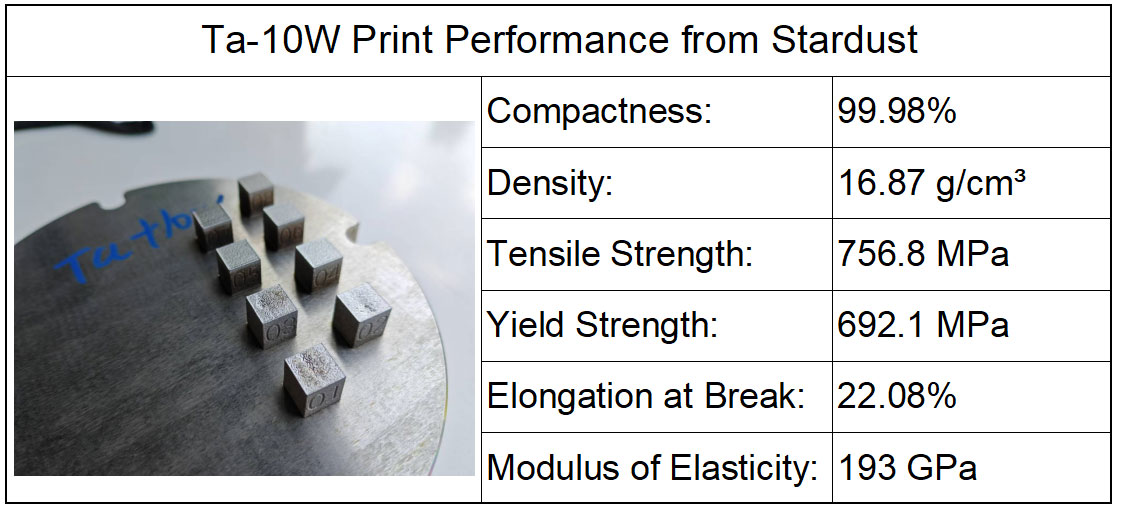

Tantalum-tungsten alloy is a high-density material with high melting point, high tensile strength, good dynamic ductility and corrosion resistance. It is used in chemical corrosion protection, machinery, aerospace and military fields.

The spherical Ta-10W alloy powder produced by Stardust Technology is made by radio frequency plasma spheroidization process, with the characteristics of high purity and low oxygen, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flowability, high bulk density and tap density.http://en.stardusttech.cn/products/57.html

For more refractory metal spherical powder products, please contact Vicky at +86-13318326185

News

-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Stardust Technology (Guangdong) Co., Ltd.

101, Building 1, Liandong Youzhi Zone, Senshuji Road, Nansha Community, Danzao Town, Nanhai District, Foshan City,Guangdong Pro.,China

QR code