-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

The choice of additive manufacturing in the high-end aerospace sector: titanium, aluminum alloy

Release time:

2023-10-09

Performance and cost are the two eternal driving forces for the development of material technology, and lightweight, integrated, structural and functional integration are common challenges faced by aircraft structural design, material application and manufacturing technology. In the past few decades, near-net forming technologies such as hot isostatic pressing, injection molding, and discharge plasma sintering have made great progress in the field of titanium alloys, but the bottleneck problems such as oxygen content and porosity have still not been effectively solved, which restricts its application in the manufacture of aviation titanium alloy structures.

From the perspective of scientific exploration and development, modern industry needs structural materials with high strength, fracture toughness and stiffness, while reducing weight as much as possible. Therefore, lightweight high-strength alloys such as titanium and aluminum and load-bearing heat-resistant alloys such as Ni-based superalloys have become the focus of new material research and development programs in various countries. In addition, these materials are also important application materials in laser additive manufacturing.

Advantages and differences of titanium alloy and aluminum alloy

Titanium alloy has high specific strength, specific stiffness and good corrosion resistance, which meets the design needs of high maneuverability, high reliability and long life of aircraft, and its application level has become an important symbol to measure the advanced degree of aircraft material selection.

Titanium alloy and aluminum alloy are widely used in aerospace, automotive, mechanical manufacturing and other fields because of their excellent low density and structural strength. Especially in the aviation industry, they play a very important role and are the main structural materials of the aviation industry. Although titanium alloys are about two-thirds heavier than aluminum alloys, their inherent strength means that less amount can be used to achieve the desired strength. Because of its strength and low density, titanium alloy has become an important material to reduce fuel costs, and is widely used in aircraft jet engines and various spacecraft. Aluminum alloy is the most widely used and most common automotive lightweight material at this stage, and its density is only one-third of that of steel. Studies have shown that aluminum alloy can be used up to 540kg in the vehicle, in which case the car will lose 40% of its weight. Audi, Toyota and other brands of vehicles using all-aluminum body is a good example.

Since both materials have high strength and low density, other factors must be considered when selecting alloys.

In critical situations where high strength and low weight are required, every gram counts, but if higher strength parts are required, titanium is the best choice. Therefore, titanium alloys are used in the manufacture of medical devices/implants, complex satellite components, fixtures and stents.

In terms of cost, aluminum is the most cost-effective metal for machining or 3D printing; The cost of titanium is higher, but the fuel saved by lightweight parts for aircraft or spacecraft will bring great benefits, and the service life of titanium parts is longer.

In terms of thermal properties, aluminum alloy has a high thermal conductivity and is often used to make radiators; For high temperature applications, the high melting point of titanium makes it more suitable, and aircraft engines contain a large number of titanium alloy components.

Titanium's corrosion resistance and low reactivity make it a biocompatible metal that is widely used in the medical field (such as surgical instruments). Ti64 is also very resistant to salt environments and is often used in Marine applications.

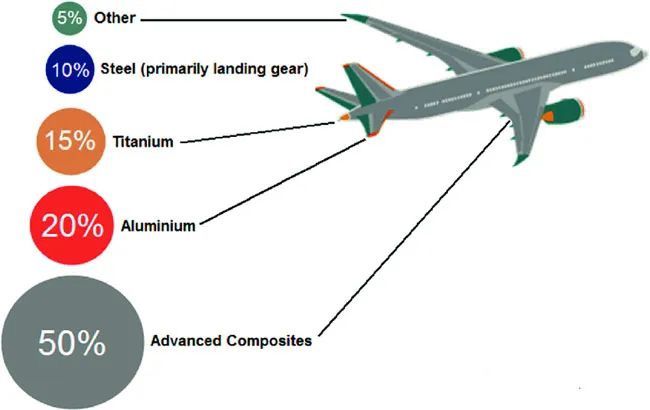

In the aerospace field, aluminum and titanium alloys are widely used. Titanium alloy has the advantages of high strength and low density (only about 57% of steel), and its specific strength (strength/density) is far more than other metal structural materials, which can make parts with high unit strength, good rigidity and light weight. The engine components, skeleton, skin, fasteners and landing gear in the aircraft are all made of titanium alloy. In addition, it was found that aluminum alloy is suitable for working in an environment below 200 ° C, and the aluminum used in the fuselage of Airbus A380 accounts for more than 1/3, while the C919 also uses a large number of conventional high-performance aluminum alloy materials. Aluminum alloy is used in aircraft skin, spacer frame, wing ribs and other parts.

Titanium alloy has become one of the most expensive metal materials due to its high melting point and difficult to process properties. However, the lightweight, high strength and high temperature resistance characteristics of Ti6Al4V titanium alloys have made them attractive in the aerospace field. Its application range includes the blades, discs, cartridges and other parts of the engine fan and compressor working in the low temperature section, and the operating temperature range can reach 400-500℃. In addition, it is used to manufacture fuselage and capsule components, rocket engine cases, and helicopter rotor hubs. However, due to its poor electrical conductivity, titanium is not an ideal choice for electrical applications. Although the price of titanium alloy is relatively high, its high temperature and corrosion resistance can not be replaced by other lightweight metals.

铝 Aluminum-based alloys are widely used in industry because of their excellent physical and mechanical properties such as low density, high specific strength, strong corrosion resistance and good formability. However, from the perspective of the additive manufacturing forming process, the density of aluminum alloy is small, the powder fluidity is relatively poor, the uniformity of laying on the SLM forming powder bed is poor or the continuity of powder transport in the LMD process is poor, so the precision and accuracy of the powder laying/feeding system in the laser additive manufacturing equipment is high.

铝 Aluminum-based alloys are widely used in industry because of their excellent physical and mechanical properties such as low density, high specific strength, strong corrosion resistance and good formability. However, from the perspective of the additive manufacturing forming process, the density of aluminum alloy is small, the powder fluidity is relatively poor, the uniformity of laying on the SLM forming powder bed is poor or the continuity of powder transport in the LMD process is poor, so the precision and accuracy of the powder laying/feeding system in the laser additive manufacturing equipment is high.

At present, the main aluminum alloys used in additive manufacturing are Al-Si alloys, among which AlSi10Mg and AlSi12 with good fluidity have been extensively studied. However, because Al-Si alloy is a cast aluminum alloy, despite the use of optimized laser additive manufacturing process to produce, but its tensile strength is still difficult to exceed 400MPa, limiting its use in the aerospace and other fields of service performance of the more demanding bearing components.

Modern aerospace components face a series of demanding requirements, including lightweight, high performance, high reliability and low cost. This complex structure is very difficult to design and manufacture. By innovating and developing laser additive manufacturing technology for aerospace typical aluminum, titanium, and nickel-based components, we can not only achieve lightweight and high performance on material selection, but also reflect the development trend of precision and net forming of additive manufacturing technology. By realizing the integration of material-structure-performance additive manufacturing, we can apply additive manufacturing technology to major projects in the aerospace field.

Stardust Technology (Guangdong) Co., LTD., using advanced equipment technology, research and development of spherical titanium alloy powder, with high purity, high sphericity, excellent fluidity, no satellite ball, loose density, no hollow powder and other characteristics. It has a high satisfaction evaluation in the industry. Welcome to consult: Cathie Zheng (+86-13318326187).

Statement: This article is from [titanium industry], reprinting this article must be approved by the author. If there is any copyright problem with the content or pictures, please contact us for processing

News

-

-

-

National Titanium and Rare Metal Powder Metallurgy Engineering Technology Research Center

-

Guangdong Metal Powder Material Engineering Technology Research Center

-

Guangdong Powder Metallurgy Industry Technology Innovation Alliance

-

Guangzhou Powder Materials and Precision Parts Manufacturing Engineering Technology Research Center

-

Stardust Technology (Guangdong) Co., Ltd.

101, Building 1, Liandong Youzhi Zone, Senshuji Road, Nansha Community, Danzao Town, Nanhai District, Foshan City,Guangdong Pro.,China

QR code